In the article "Table for a milling cutter" It was told how to build a table with a worktop with a milling cutter installed. In this article, we will look at how the Master made the countertop.

Tools and materials:

- Aluminum guides;

-Dust collector socket;

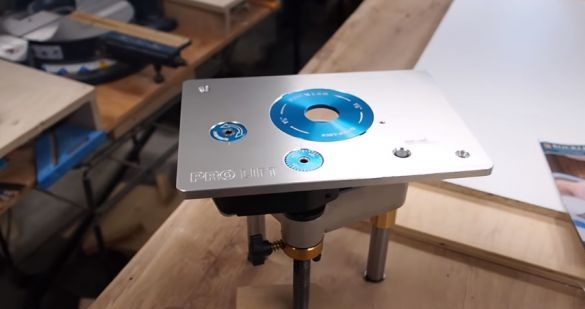

-Lift for the milling cutter;

-Fasteners;

-Wind screws;

-Furniture legs;

-Glue;

-Plywood;

-Laminated chipboard;

Milling cutter;

-Nail gun;

-Rule;

- Electric jigsaw;

-A circular saw;

-Drill;

- Clamps;

Step One: Material Procurement

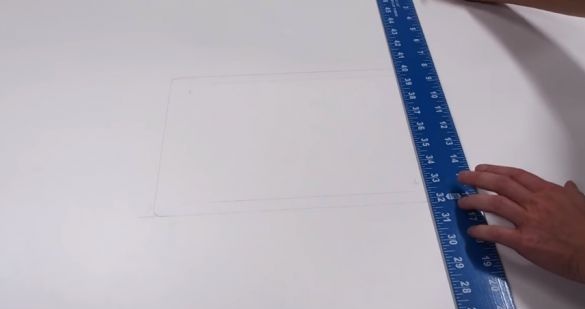

The size of the countertops is 91 * 61 cm. The top layer is laminated particleboard, the bottom plywood. On a circular, it cuts the material.

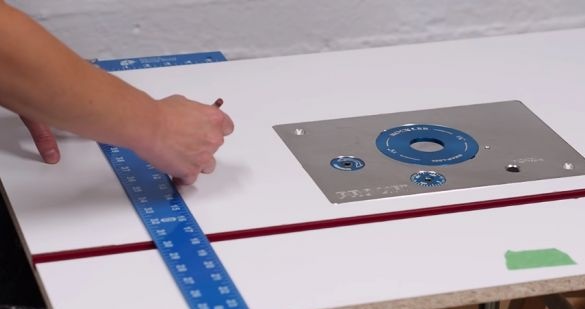

Step Two: Lift Seat

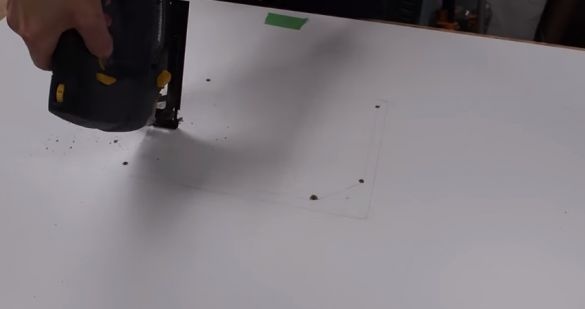

Further, the master marks the installation site of the lift. Flips it and outlines. Stepping back from the edge of the contour inward a couple of centimeters draws another contour.

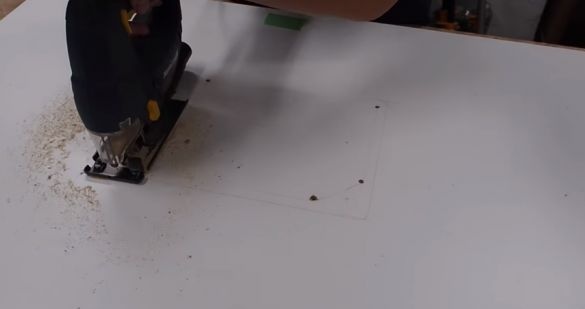

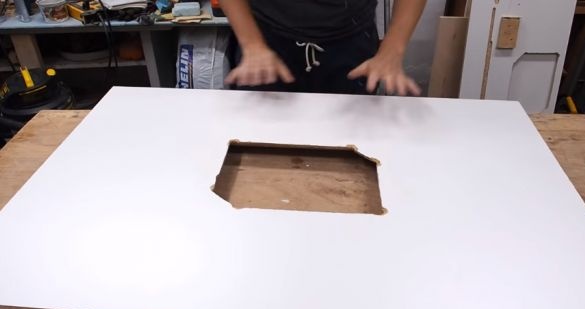

Cuts a niche around the perimeter of the inner contour.

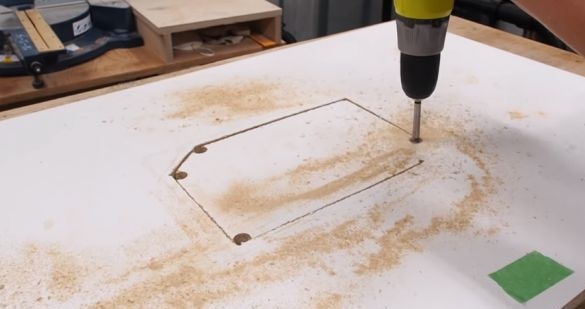

The lift table should be flush with the surface of the worktop. The master makes a side of the bar around the niche and the milling cutter selects the top layer to the thickness of the lift plate.

Installs a lift in a niche. Checks the plane.

As you can see, the plane does not coincide, but in the future the master will make them at the same level.

Step Three: Guides

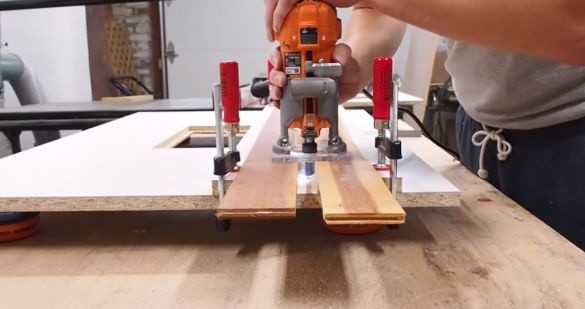

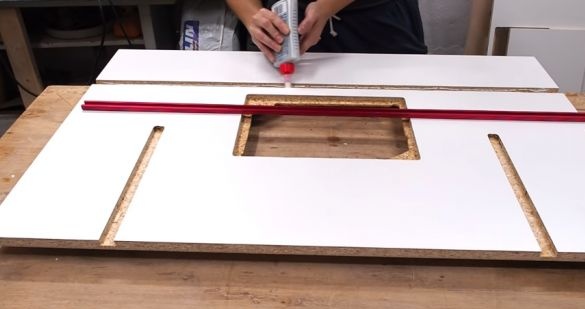

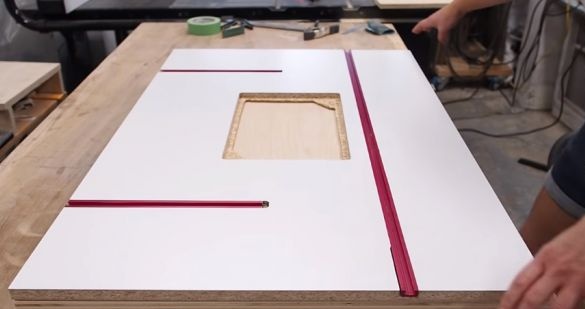

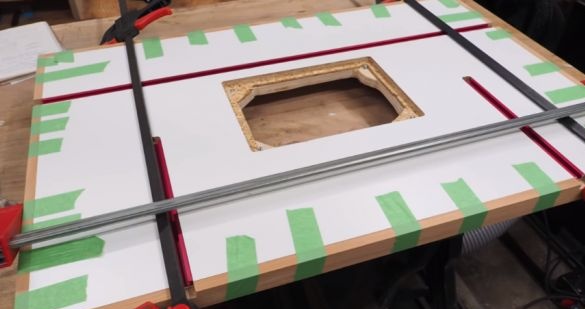

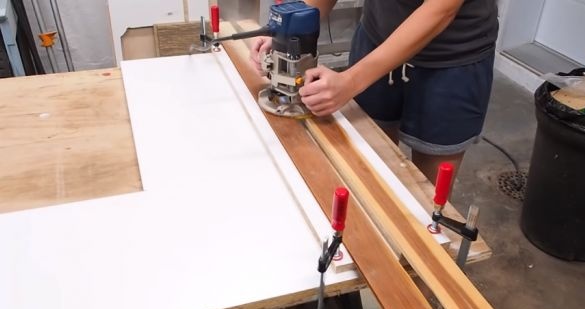

Marks the installation locations of the rails. Milling cuts out grooves.

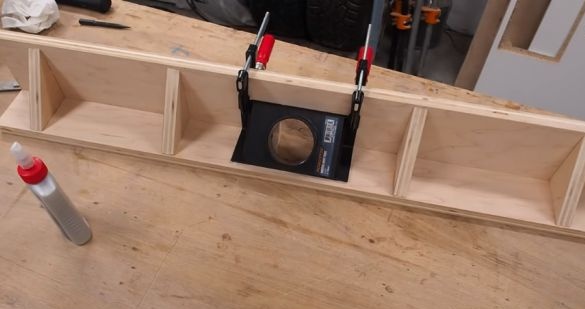

Coats the seats with glue. Sets guides. Clamps with clamps.

Step Four: Bottom Sheet

In plywood sheet cuts out the same seat for the lift.

Step Five: Build

Twists two sheets of countertops.

Handles the hem.

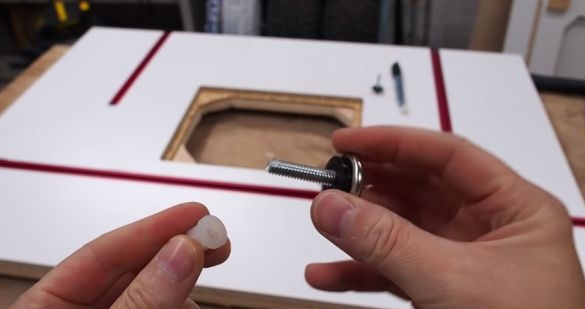

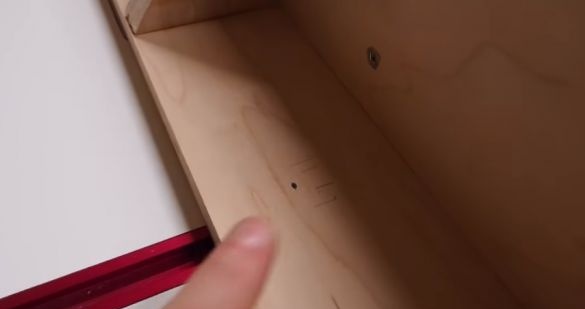

Drills holes for installing the mounting screws for the lift.

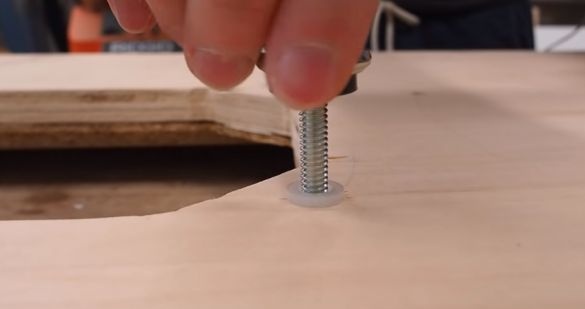

Installs screws and tightens the lift.

Screws regulates landing of the elevator in one plane with a table-top.

Installs a rail around the perimeter of the countertop.

Sixth step: focus

Now you need to make a stubborn board. Cuts boards to size. Makes a slot under the guide.

Fastens the guide.

Makes a hole for the duct.

Installs a perpendicular board and duct.

Makes a cutout for the cutter.

Installs mounting bolts.

The worktop of the milling machine is ready.

The entire process of manufacturing countertops can be seen in the video.