A simple and affordable way to make a silver ring with a nut shell and stone will be discussed in this article with the help of a master. Moreover, all these operations are not even accessible to a professional, and the machines can be replaced by manual processing. To make the ring you will need the following

Tools and materials:

-Sterling silver;

- Walnut veneer;

-Decorative rock;

- Jigsaw;

-Gas-burner;

-Pliers;

-Salt solution;

-Flux;

-Solder;

-Frame;

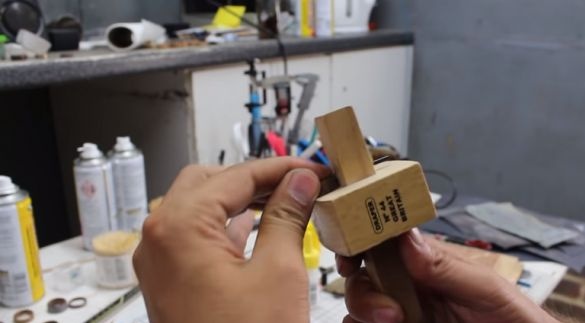

- mallet;

-File;

-Sandpaper;

-Rule;

-Scalpel;

-Super glue;

-Spray activator;

-Nadfil;

-Silver wire;

-Super glue;

-Lathe;

-Drilling machine;

-Vise;

-Tweezers;

-Wooden skewer;

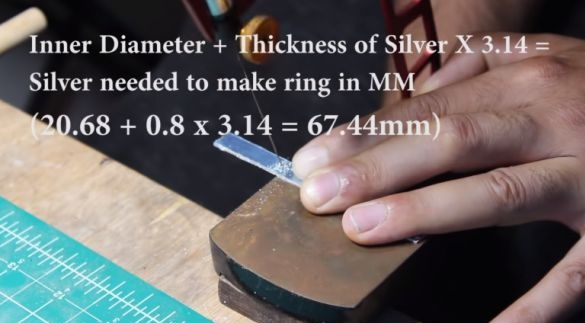

Step One: Silver Plate

The master had a silver plate. Cuts off a strip of the desired length from it (inner diameter of the ring + plate thickness * by 3.14).

For further processing, it is necessary to heat the strip.

Bends the ring.

Step Two: Soldering

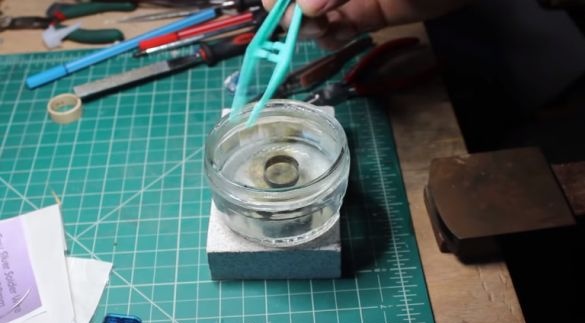

Dips the ring in saline.

Then he puts the ring seam down on the bar. A flux is placed on the seam, then solder. Heats the junction.

After soldering, the ring is again placed in saline.

Step Three: Fitting, Processing

Heats the ring again. Then it adjusts the size on the mandrel.

Sand the ring first with a file, then with sandpaper.

Step Four: Veneer

Slices a strip of veneer.

Pastes veneer on the outer surface of the ring. After gluing, veneer is ground to silver.

Step Five: Silver Wire

It cuts a groove in the veneer.

Glues a silver wire into the groove.

Grinds.

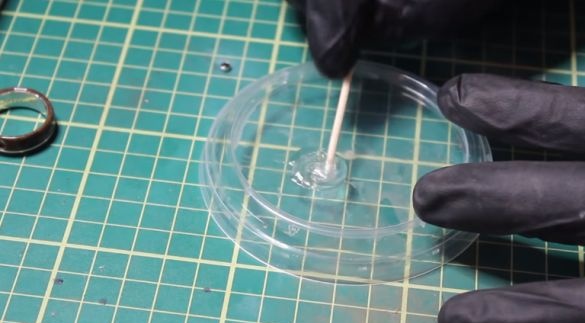

Step Six: Cover

Covers the outer surface with super glue. Apply it in several layers. Between the layers it uses a spray activator (prevents the appearance of bubbles, turbidity).

Seventh step: stone

Drills a hole in veneer (before silver). Glue a stone into the hole.

Grinds the surface again.

Fits a hole for the diameter of the pebble.

Glues a stone in the hole.

Wipe off excess glue.

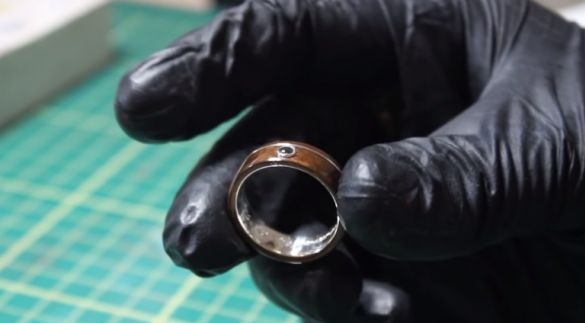

The ring is ready.

You can watch the whole process of making the ring in the video.