It will be interesting to everyone who needs to grind a large amount of solid products. Such as dried corn, wheat, and the like. For example, in the manufacture of feed.

In this article, the author of the YouTube channel "all ideas" will tell you how he made a nozzle for the grinder, which easily grinds such things.

Complex machines, tools and expensive materials are not required. Homemade can be made in 20 minutes "on the knee."

Materials

- Old pan with a lid

- Bulgarian

- A piece of steel strip

- Steel furniture corners

- Bolts for fastening to a grinder, usually M10 or M12

- Bolts with nuts M6 lamb.

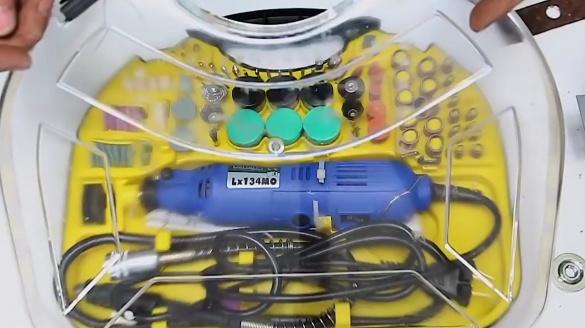

Instruments, used by the author.

- Screwdriver, step drill

- Universal key nozzle

- Engraver with nozzles, or grinder with grinding wheel

- Marker.

Manufacturing process.

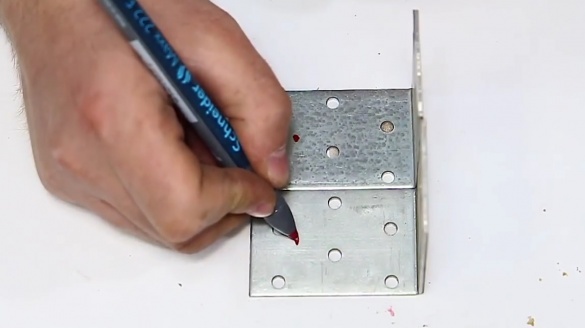

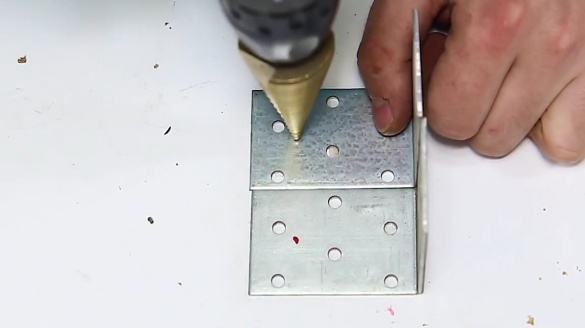

First of all, the author marks the furniture corners, and drills two holes with a diameter of 10 mm with a step drill.

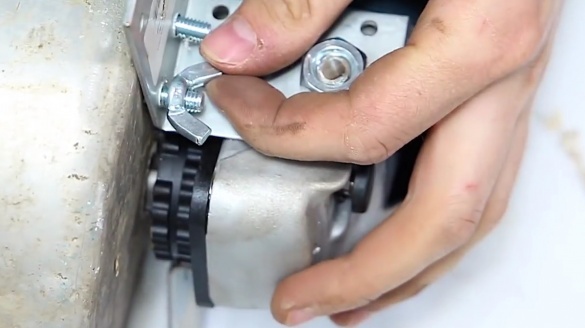

Bolts M10 corners - holders to the grinder.

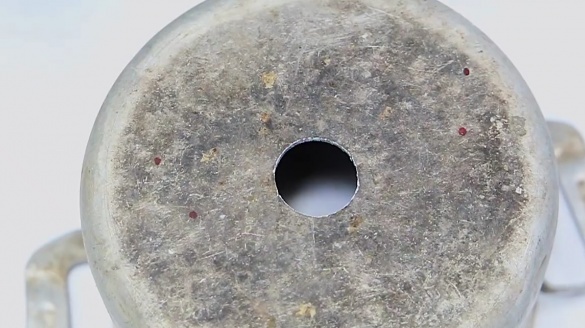

Having marked the center of the old aluminum pan, drills a hole for the flange of the grinder.

Next, removes the clamps from the shaft of the grinder, puts on a bucket and tightens the clamping nuts.

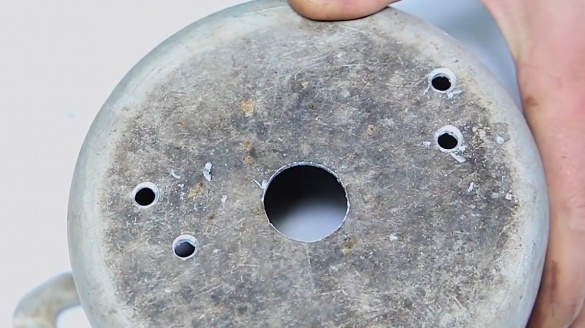

The next step marks the holes for the mounting bolts, drills holes with a diameter of 6 mm.

Inserts M6 bolts into the holes and baits the wing nuts.

Now clamps the bolts with a universal key-nozzle.

Then, in the center of a piece of steel strip, drills a hole for the shaft of the grinder.

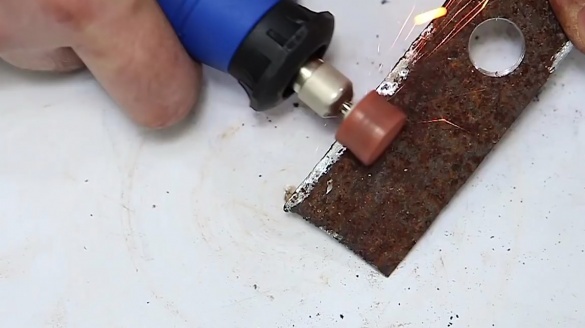

Further, the author, using an engraver with a barrel nozzle, grinds the sides of the strip, receives a knife.

Sets the knife on the shaft of the grinder, clamps the nut.

Everything is ready for testing, the author will grind the corn. Depending on the duration of operation of the device, the grinding also changes.

Here it turns out in a couple of minutes from a kilogram of corn.

Thanks to the author for interesting and useful device!

When working with this device, carefully select the groats, do not allow metal objects, nails.And follow safety precautions.

All the good tools!