This article will be interesting to everyone who deals with metal, and especially with wire. Often it is necessary to bend various figured details from a wire. Pliers are usually used for this, but this is very problematic with a stiff and fairly thick wire. Angles can be uneven.

In this article, Roman, the author of the YouTube channel "all ideas" will tell you how he made a simple but quite useful device for such work. It allows you to work with wire of various diameters and different materials.

Materials

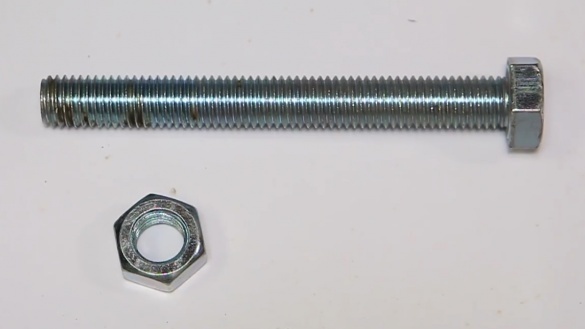

- Bolt and nut M14

- Nail 140 mm.

Instruments, used by the author.

- Bulgarian

- Welding machine

- Screwdriver

- Drill 6.5 mm

- Vise

- File

- Marker.

Manufacturing process.

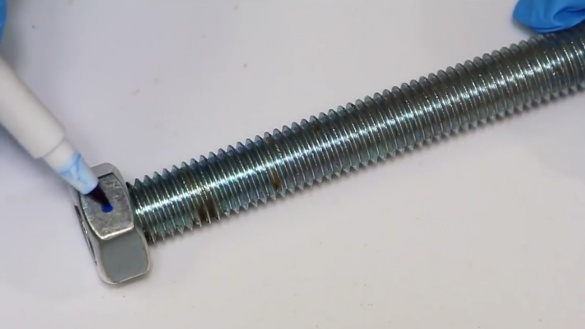

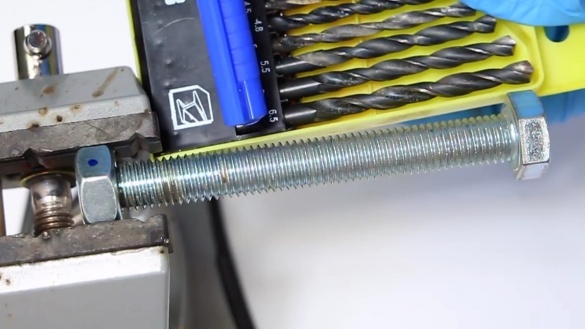

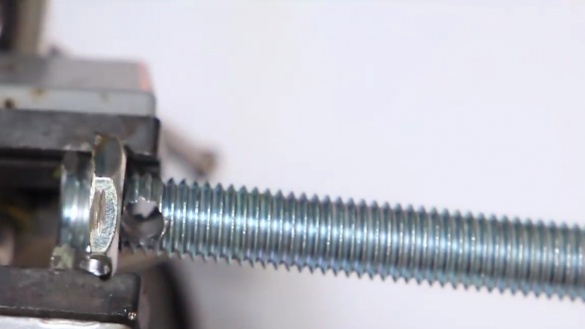

First of all, the novel tightens the nut on the edge of the bolt, and marks the center of one of the faces. Then clamps it in a vice.

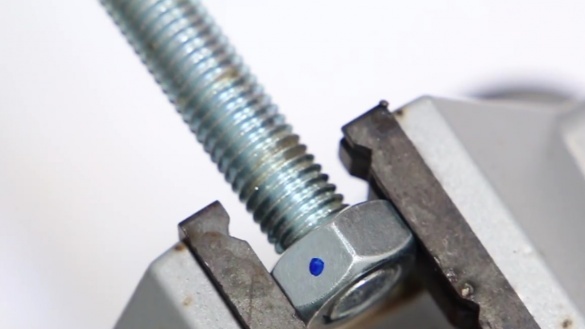

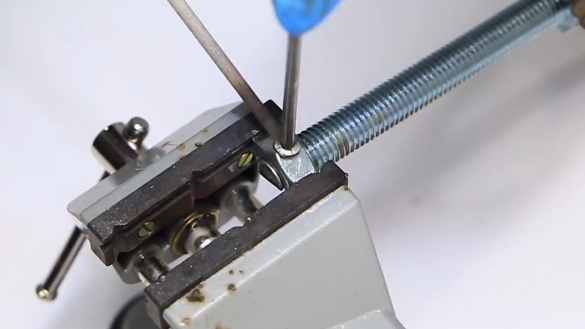

Further, having outlined a center with a thin drill, it makes a through hole with a 6.5 mm drill.

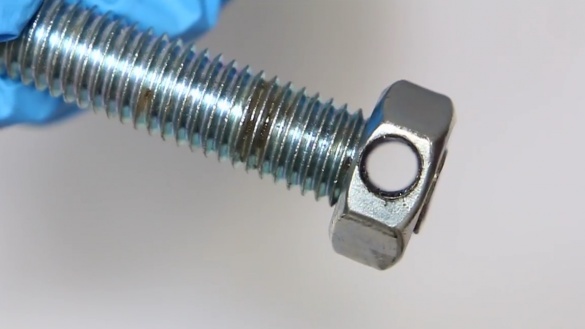

It turns out this kind of blank.

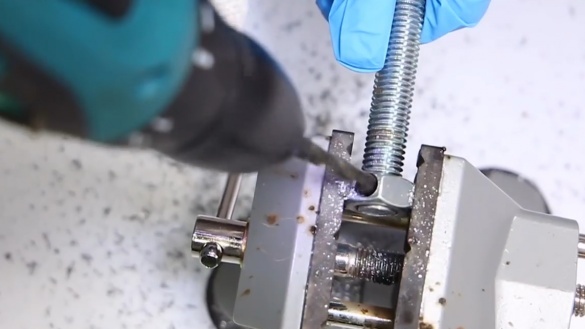

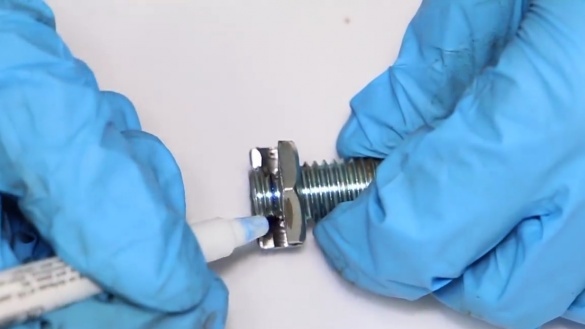

The next step in marking the nut.

Again clamps in a vice and cuts off only the nut without affecting the bolt.

Almost finished part.

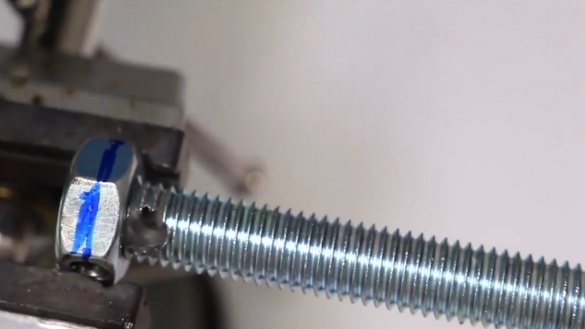

Now marks and cuts the bolt.

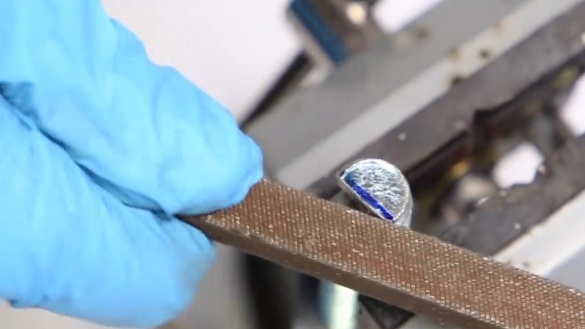

It handles faces with a file.

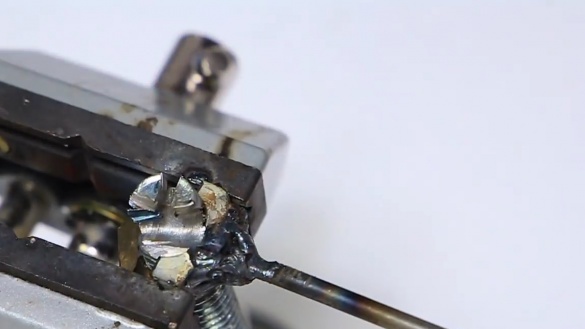

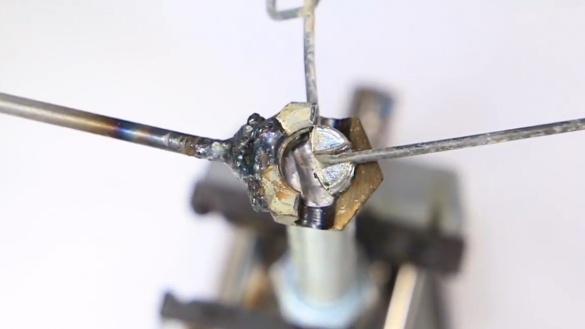

At this point, the details look like this.

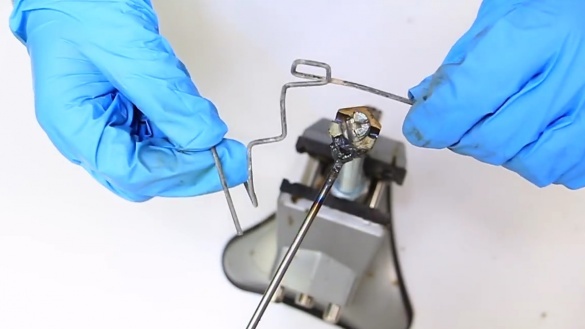

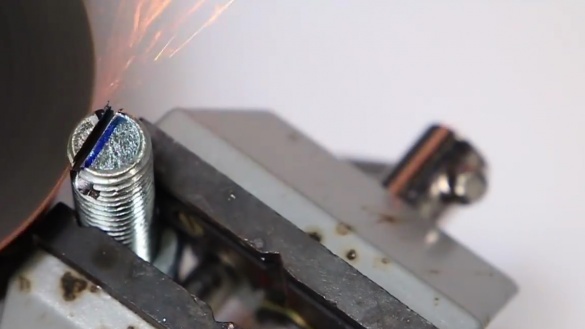

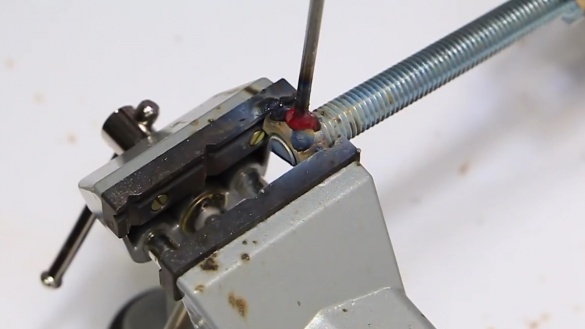

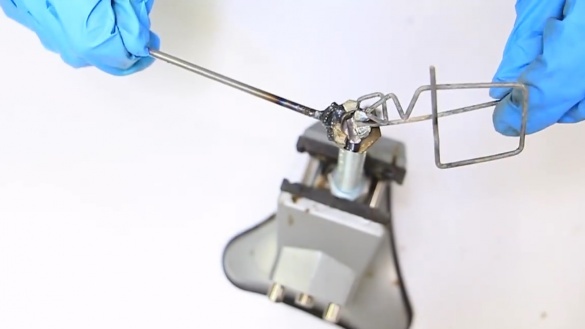

Roman begins welding work. Clutching a nut in a vice, welds a 140 mm nail to it with a hat, nut.

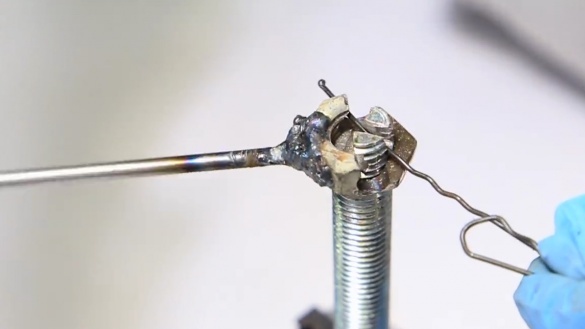

The author remains to make the last incision grinder.

So, the bending tool is ready!

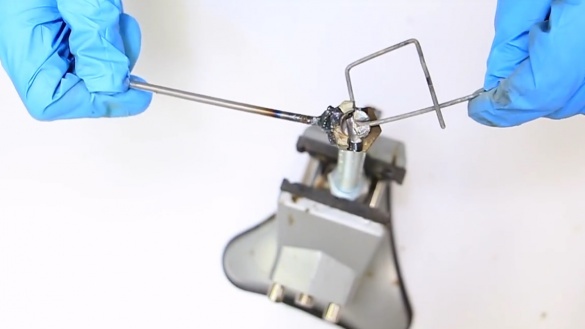

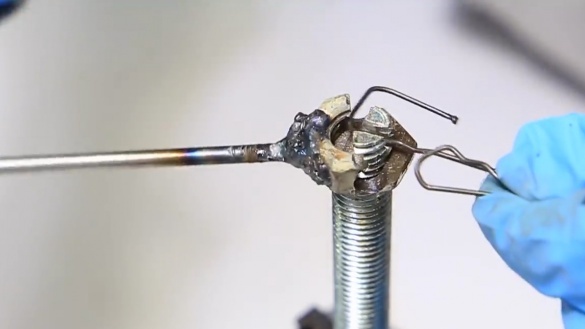

So, it's time to test the capabilities of this device. As you can see, Roman easily bent a three-dimensional figure of steel wire.

Moreover, the distance between the bends can be quite small.

With very thin materials, too, copes with excellent.

Of course, you can take the original bolt and nut and a much larger size, and instead of a nail, weld a piece of reinforcement. Then it will be possible to bend even studs and steel bars.

Thanks to Roman for an interesting and useful homemade!

Good mood to you all!