The master is fond of miniature homemade, and this time he decided to make a mini-anvil. Such an anvil will be an excellent gift to a friend of the blacksmith and not only him.

To make the anvil, the master used the following

Tools and materials:

- Beech wood;

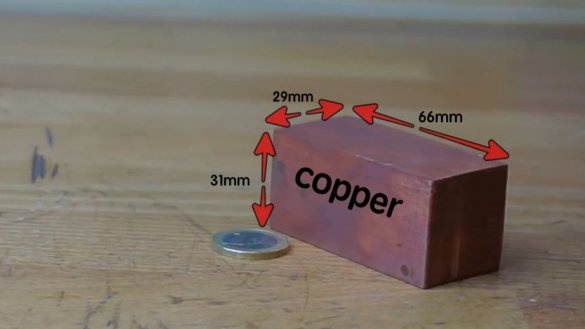

-Copper block;

-Chain;

-Rule;

-Marker;

-Paper;

-Scissors;

-Vise;

-Drilling machine;

- Hacksaw for metal;

-File;

-Dremel;

-Sandpaper;

- Clamps;

- Joiner's glue;

-Metal strip;

-Copper nails;

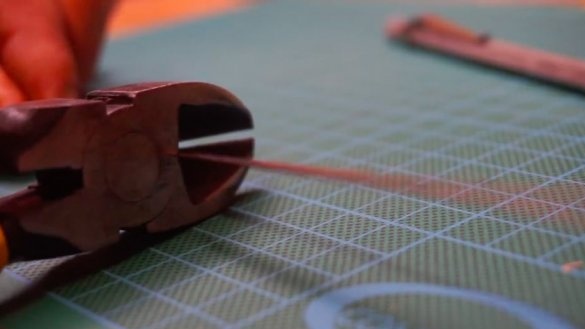

-Nippers;

-Pliers;

-Hammer;

- brush;

-Varnish;

-Screw;

-Screwdriver;

-Polishing wheel;

-Polishing paste;

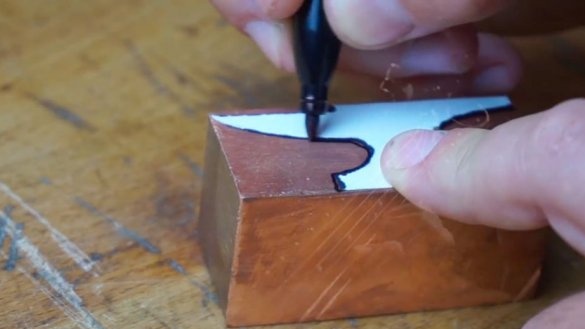

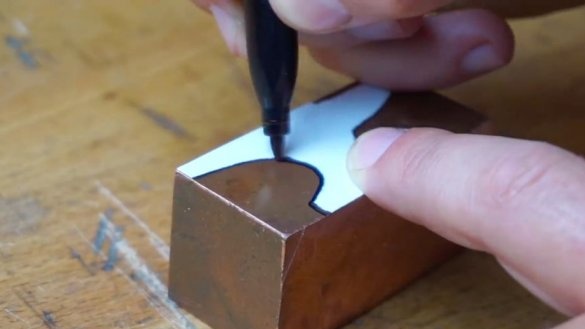

Step One: Template

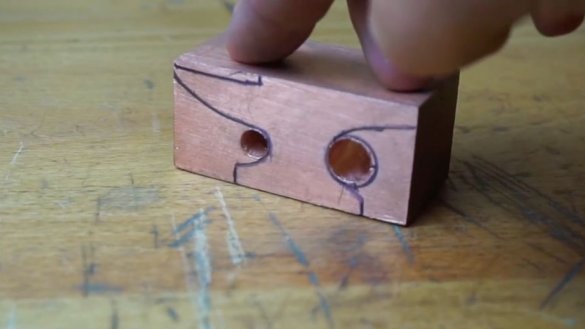

On a piece of paper draws an anvil pattern. Then transfers the drawing to the copper billet.

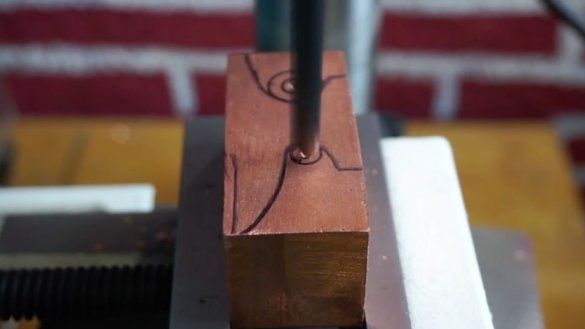

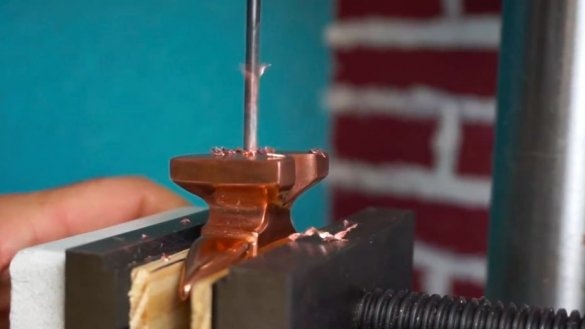

Step Two: Block Processing

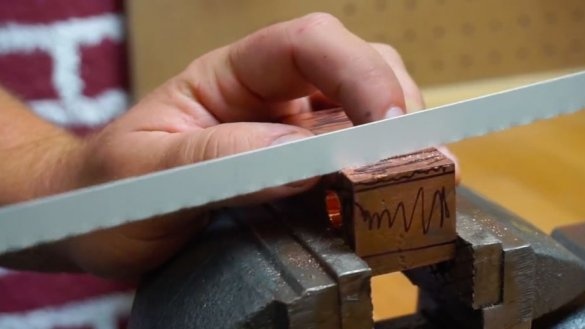

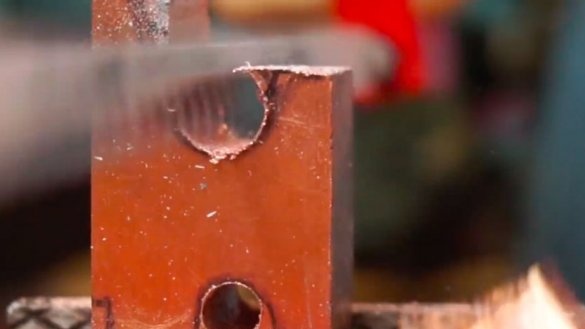

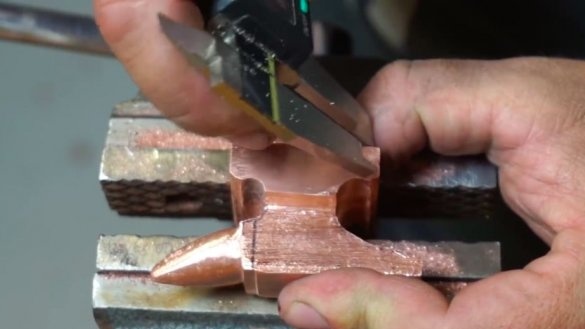

According to the pattern, it starts to cut metal. Drills holes to facilitate machining. Saw off the excess parts.

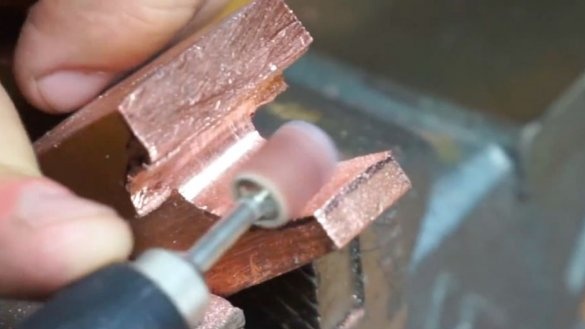

Shapes the rough top of the anvil.

Cut horn and tail.

Step Three: Polishing

Sanding with an anvil sandpaper with a grain size of 200 to 1000. Polishes with polishing paste.

Step Four: Stand

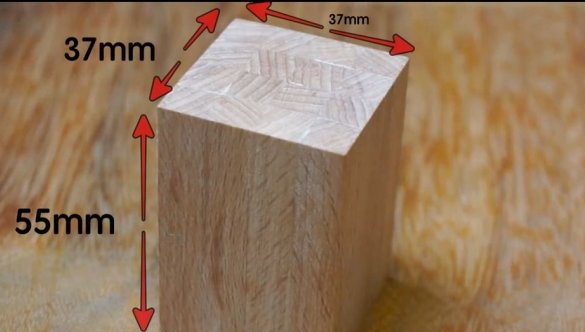

The master made a stand from pieces of beech wood. Cut pieces to size. Glued them into one block.

Covers the stand with stain. Two strips fasten on copper nails.

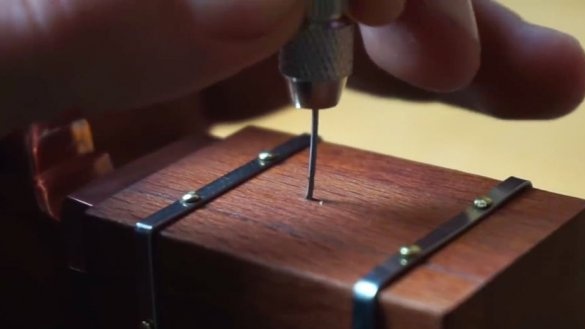

Step Five: Join Parts

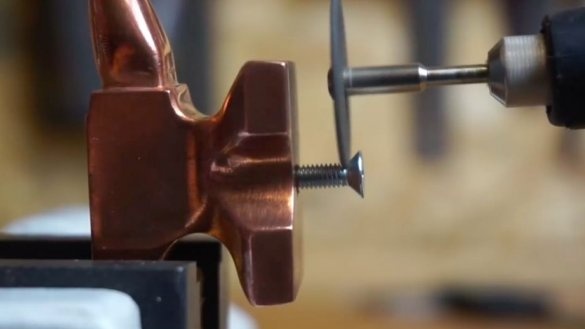

The master uses a screw to connect the anvil and the stand. Drill a hole in the lower part of the anvil, cut the thread and tighten the screw. Cuts off the screw head. At the top of the anvil, drills a hole and installs a threaded sleeve. Twists two parts together.

With the final step, the master sets the chain.

The miniature anvil is ready.

On the video you can see the manufacturing process in more detail.