According to the master, the efficiency of the internal combustion engine is 18-20%. Those. 4/5 of the energy is wasted, and part of it just flies into the exhaust pipe.

Students from India decided to convert part of the thermal energy of the exhaust gas into electrical energy. The device operates on Seebeck elements. The efficiency of the device is 3%. Considering that up to 60% of the engine’s thermal energy flies through the exhaust pipe, this is 1.3% of the engine’s energy. On the one hand, a little, but given the amount of equipment worldwide, the resource savings are huge (of course, you still need to consider the costs of manufacturing and maintaining such devices).

The device, assembled by students, is designed to charge gadgets and perfectly paid off.

Tools and materials:

-Aluminum block 12x4x4.5 cm;

- Duralumin strips of 3x50 mm and 6x20 mm;

- Seebeck Modules - 3 pcs;

USB cable

-Insulating tape;

- clamps;

-Fasteners;

- thermal paste;

-Hacksaw;

-Vise;

-Lathe;

-USHM;

-Screwdriver;

-Keys;

-Scissors;

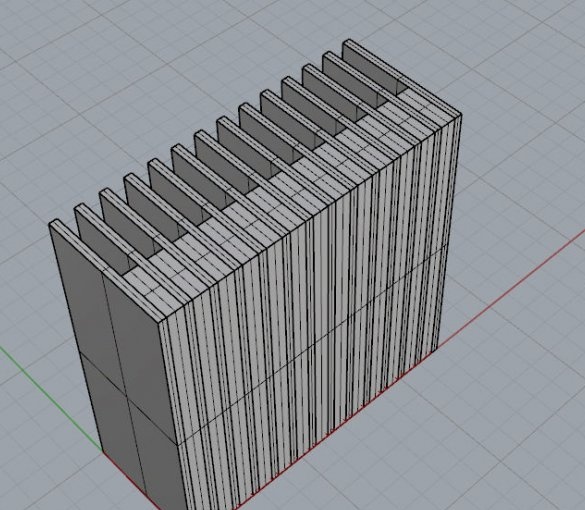

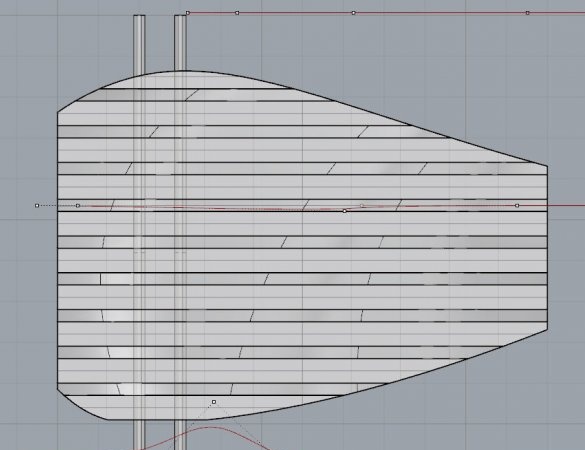

Step one: aluminum heat transfer unit

The heat transfer unit will transfer the thermal energy of the exhaust gases from the knee of the exhaust pipe to the Seebeck elements. The exhaust pipe is round, and the unit must be prepared so that it fits as tightly as possible to the pipe. The Seebeck module size is 4x4 cm. There are three modules. So you need a 12x4 block.

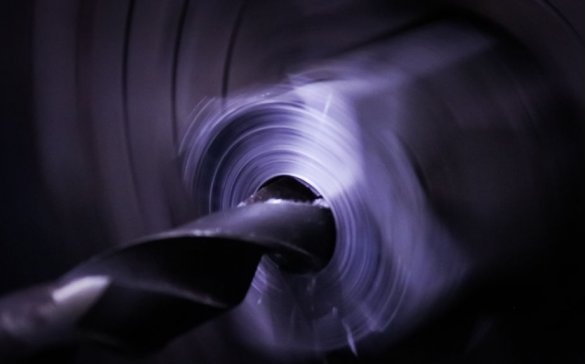

The master polishes the block. Cut the block in half. Fastens in the lathe chuck by folding both halves. Drills a through hole with a drill equal to the radius of the exhaust pipe.

Step Two: Radiator

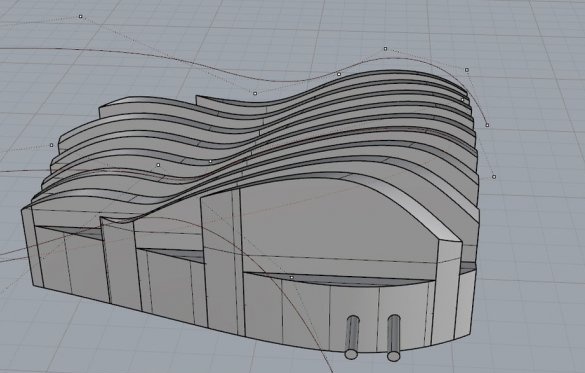

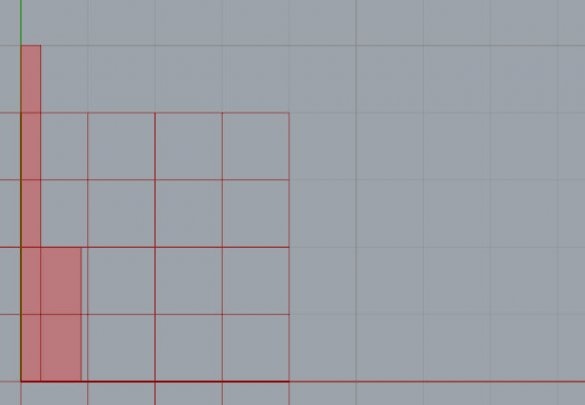

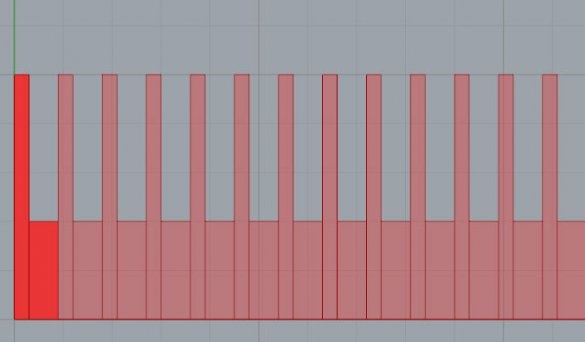

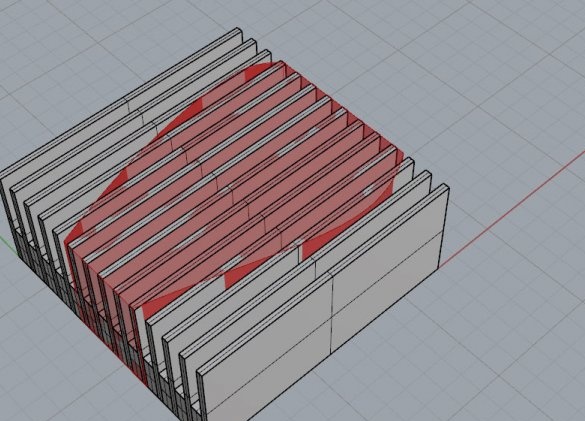

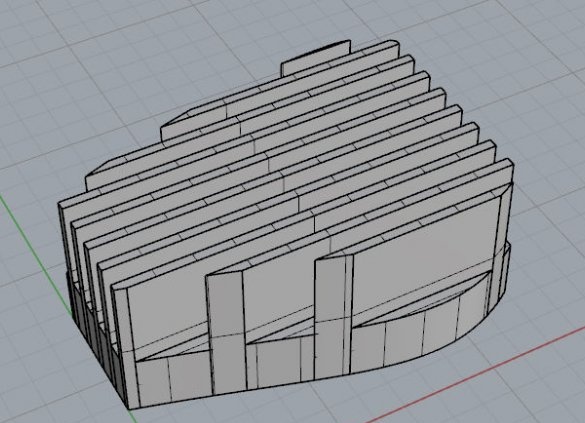

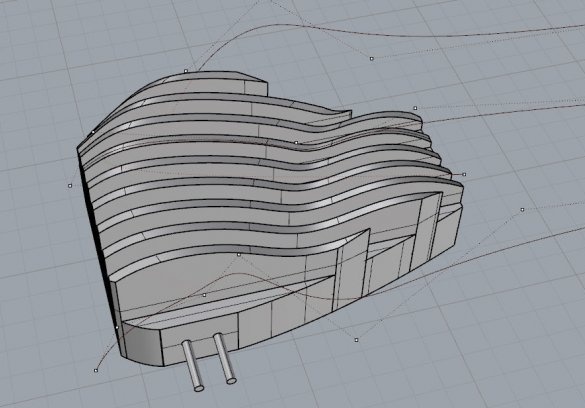

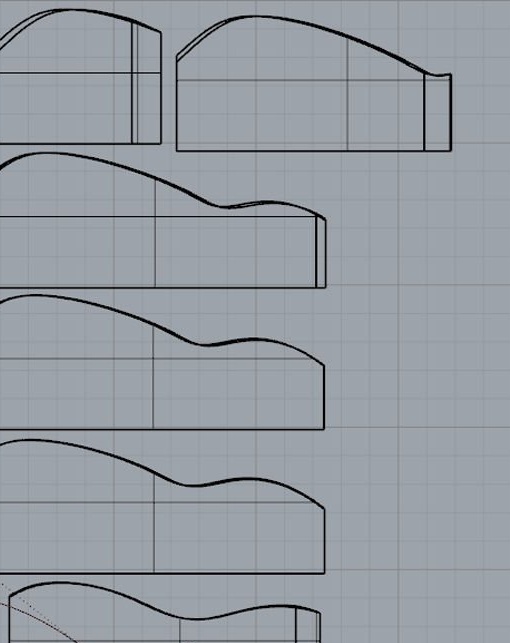

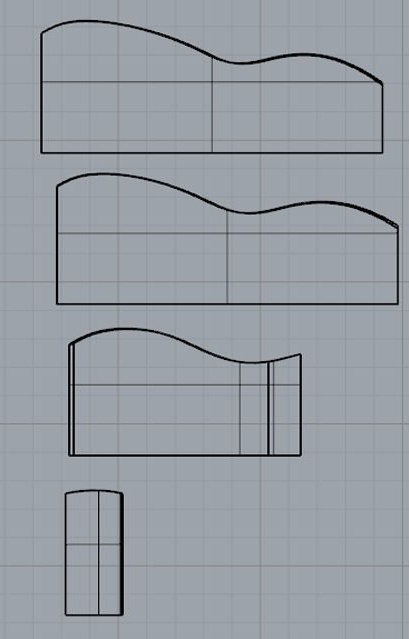

Students calculated the radiator parameters in the Grasshopper for Rhino program. Modeling radiator design.

Heat dissipation.

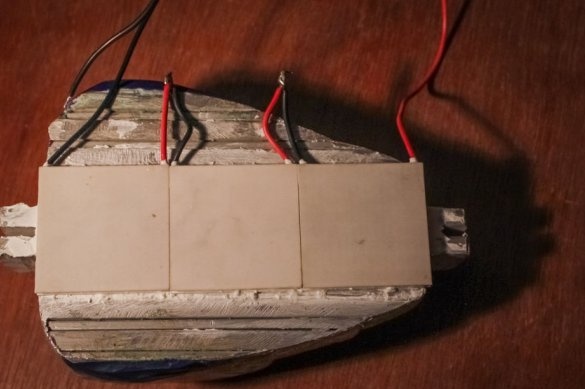

The radiator built by students is made of duralumin plates. The plates were cut to size, cut out, turned.

The prepared parts were assembled in one block.

Step Three: Testing

After assembling the radiator, students previously tested the device.Heating with an alcohol burner, the block at the output of the Seebeck elements showed 5 V.

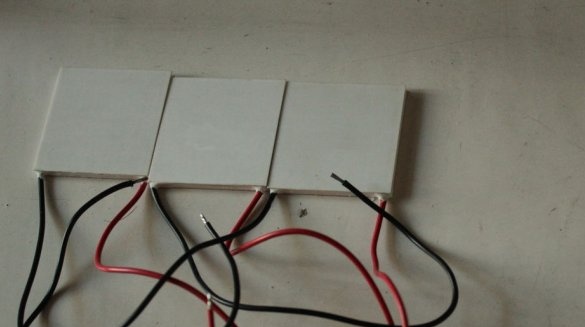

Step Four: Seebeck Modules

Seebeck modules convert thermal energy into electrical energy. When installing the modules, it is necessary to correctly orient their sides. For this, it is necessary to apply 2-3 V to each module for a short time. One side of it will be heated, the other will be cooled. It is necessary to mark one of the sides and during assembly all the hot and cold sides should be on one side.

For better thermal conductivity, prior to assembly, apply thermal grease to the mating parts.

Step Five: Installation

The assembled device is fixed on the elbow of the exhaust pipe with clamps. Connects wires to module outputs. Laying wires to the luggage compartment. Then, through the adjustable power supply, you can charge the gadgets.