Colds came, there was an urgent need for heating the working room, especially this concerns the garage. If your stove is already old, and you want to collect something new, you can take a closer look at this project.

In this project, we will look at how to make a productive and simple furnace from a profile pipe. The stove works on the principle of buleryan, all the heat generated from the combustion of firewood is immediately spent on heating the air. In fact, you burn a bonfire in the garage, only carbon dioxide and smoke goes out. The author adapted a small fan for the furnace, which will allow even more actively to remove heat from the walls of the furnace. If you are interested in the project, I propose to study it in more detail.

Materials and tools used by the author:

Material List:

- profile pipes;

- thick sheet steel;

- handle for the door;

- door hinges (or you can do it yourself from bolts and nuts);

- heat resistant paint;

- fan (optional);

- chimney.

Tool List:

- grinder;

- welding machine;

- tape measure, pencil and so on.

Furnace manufacturing process:

Step one. Fabrication of the main frame

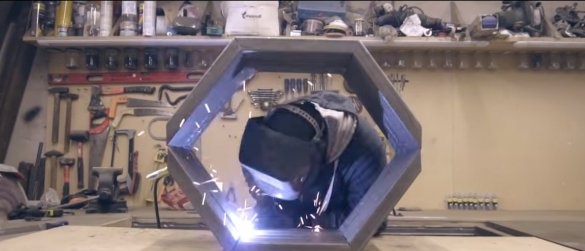

The main frame of the furnace is made of a rectangular profile pipe, we cut the desired amount depending on the length of the furnace that you need. The longer the oven is, the more heat it can produce.

In profile pipes, parts must be cut so that they can all be bent and then welded. In the author, as a result, the furnace frame is a hexagon. Cold air will enter into the pipes below, and hot will come out above. So the walls of the furnace will not overheat, and the room will be well heated.

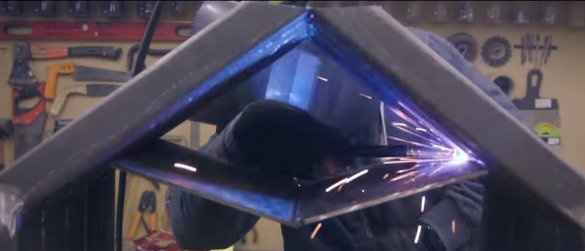

In the upper part of the furnace, the author welded a spacer. It is needed so that the fire does not directly go into the pipe, but spins in the furnace, as a result, the efficiency increases.

Step Two Walls, legs and door

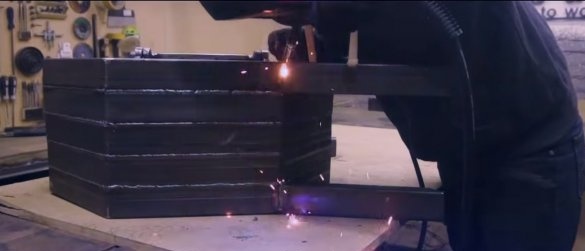

The walls of the furnace are made of thick sheet steel, since the temperature inside can be considerable. We cut hexagons and weld to the frame, welds should be of high quality so that smoke does not escape anywhere.

We also make legs from a profile pipe.

In the front part we cut a rectangular hole and weld it from the inside with steel plates, they are needed for a snug fit of the door. We make the door from the cut out part, scald it with a rectangular profile pipe. As a result, it remains to hang the door on good strong hinges, make them yourself or buy ready-made ones, you decide.

Step ThreeBlower and locking mechanism

We install a reliable locking mechanism on the door, we make the handle more authentic, since it can become very hot.

We also install a blower, the author made it from a rectangular pipe, installing a damper inside. We weld the blow to the bottom of the furnace.

Step Four Final touches and testing

At the end, we weld the exit to the chimney, the author cuts a hole using a grinder.

The oven can be painted, otherwise it will quickly rust due to heating. Paint must be used refractory.

The oven can be tested, it works perfectly, the author is satisfied. To increase performance, a blower fan can be installed in the lower part for ventilation. If everything is done hermetically, you can quite accurately control the burning rate using a blower. Now the author homemade certainly not freezing. On this project is over, I hope you liked the homemade. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!