In this article, we will consider how the author solved the problem of lighting the working area of a sewing machine. As you know, the body of the sewing machine is located on top and obscures the work area. The master installed additional lighting on the case.

Tools and materials:

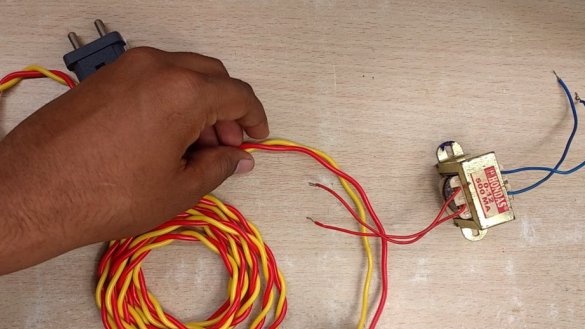

-Transformer;

-Rectifier;

-The wire;

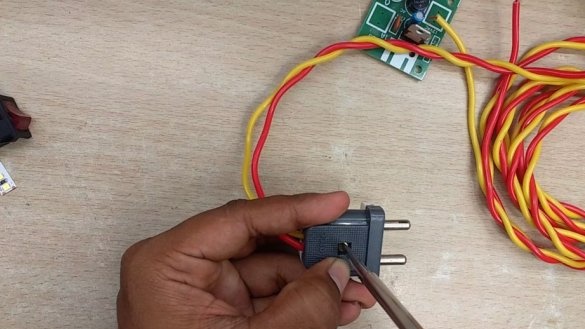

-Fork;

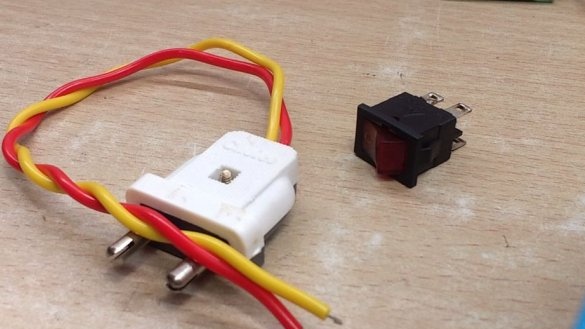

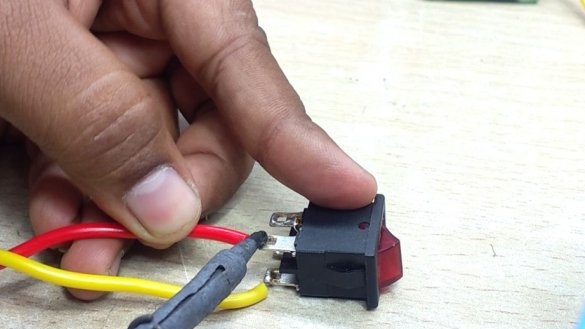

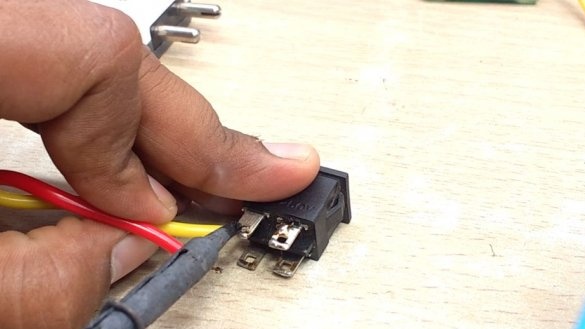

-Switch;

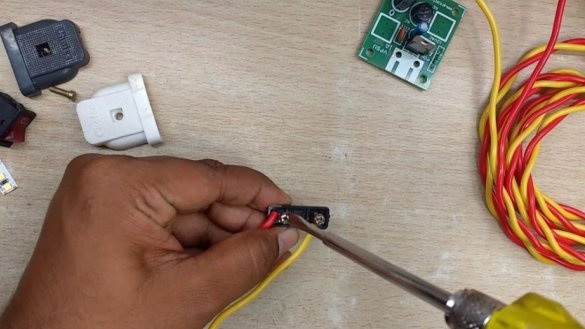

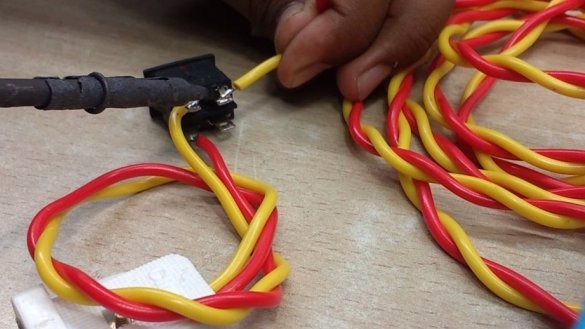

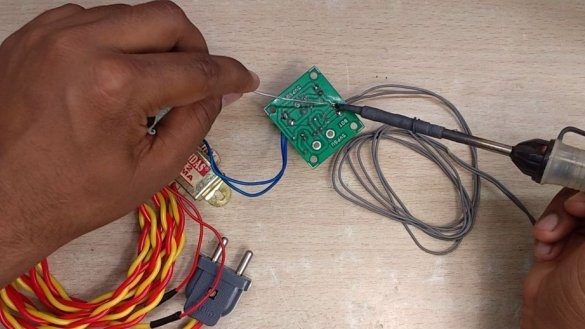

-Soldering accessories;

-Drill;

-Fasteners;

-Screwdriver;

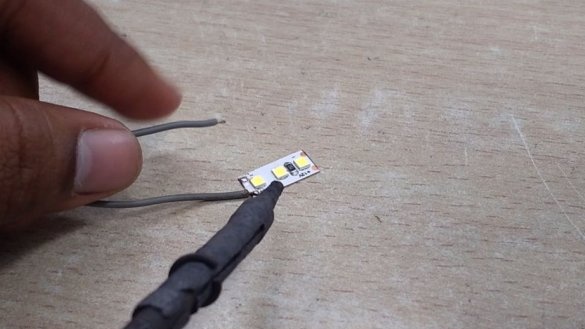

-LED Strip Light;

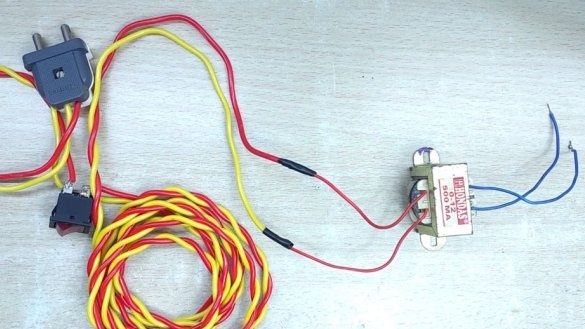

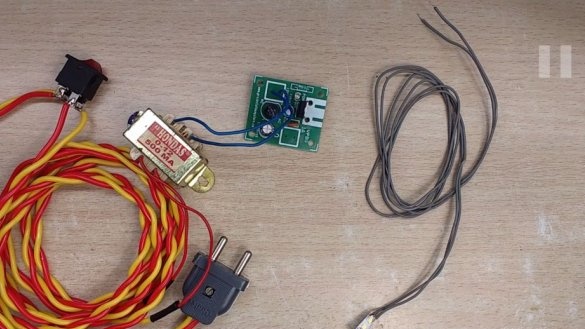

Step One: Transformer

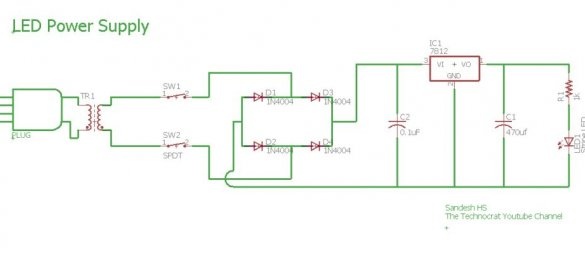

A 220 V domestic network is supplied to the primary winding of the transformer. The secondary output is 12 V. The master connects the plug, switch and transformer to the circuit.

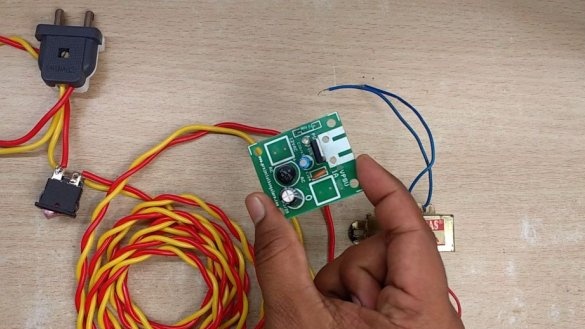

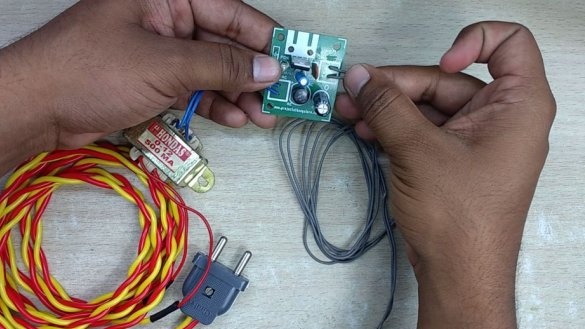

Step Two: Rectifier

The current at the transformer output is the same as on the primary winding i.e. variable, and for LEDs you need a constant. To solve this issue, the master, in the circuit between the transformer and the LED strip, installs a rectifier.

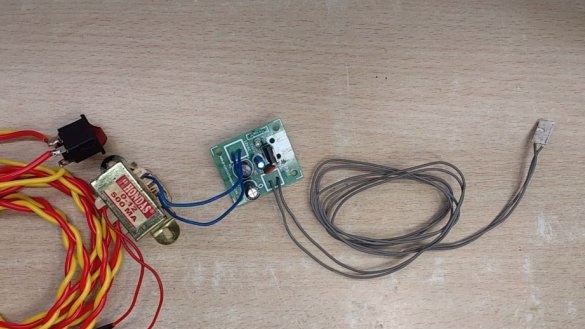

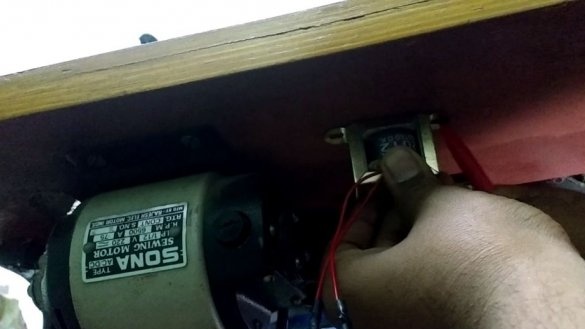

Step Three: Installation

The transformer and rectifier master fixes under the table cover. The wire from the output of the rectifier pulls up and connects to the LED strip. LED strip secures to housing

More details can be seen in the video below.