Good afternoon!

In the manufacture of various homemade very often there is a need to fix the workpieces and if it is in the same plane, you can do it with a vice or simple clamps, but if there is a need to fix the parts at a right angle ... here an angular clamp helps a lot, but not a simple one, but with a floating clamp. The floating clip is necessary for fixing workpieces of different thicknesses.

To produce this design, you need a little sheet metal or a profile pipe, several parts machined on a lathe or made from round billets, you will also need a grinder (angle grinder), a drill or a drilling machine, a welding machine.

First, take a sheet of suitable metal 3-4 mm thick and cut a workpiece of 200x200 mm

Next, mark and cut corners from opposite sides

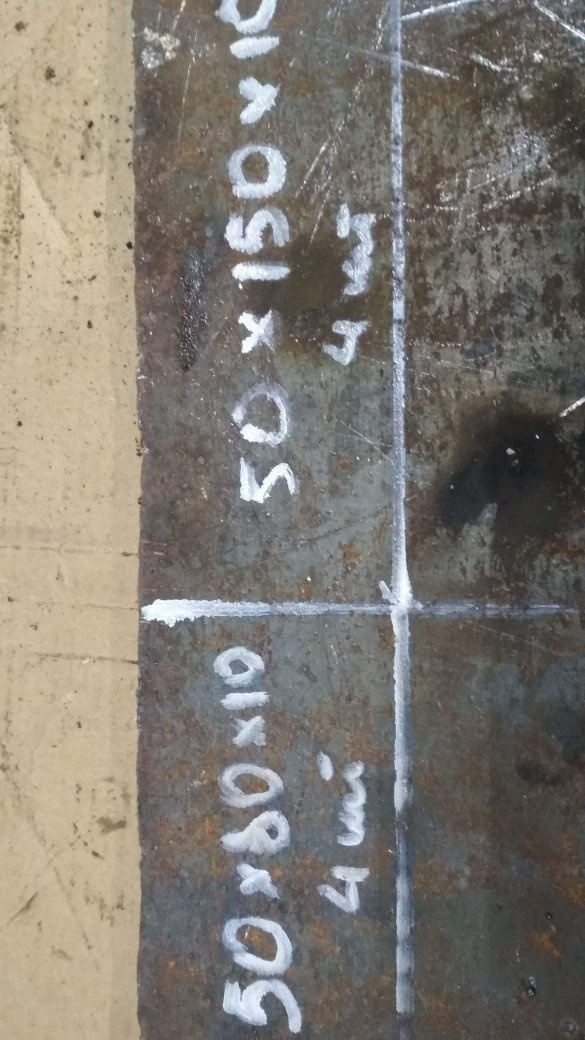

Now it's time to start manufacturing thrust pads, for this we mark out on a piece of sheet 10 mm workpieces with dimensions of 150x50 mm and 80x50, two pieces per clamp

Cut with your favorite tool - grinder

We remove chamfers for welding and we clean

We try on how you will look

Now it's up to the lathe, drew sketches and slowly everything in work

I cut out the corners of 80x80 mm from a sheet of 2 blanks, I collect a stubborn sponge of a vice

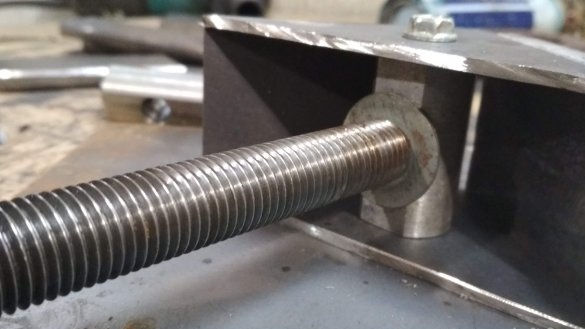

We drill a hole with a diameter of 12 mm in both plates and install a persistent barrel in them

Then I saw off a small workpiece 20x50x3 and, together with the base, drill a hole with a diameter of 12 mm and two at the edges with a diameter of 6 mm

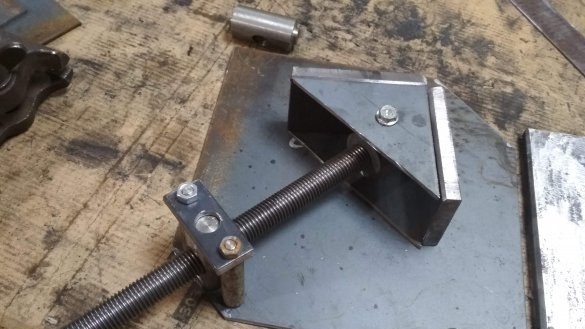

Now I proceed to the assembly-welding of parts between each other

When assembling, special care must be taken and the relative position of the parts must be constantly monitored; after tacking and checking, correct

After welding, grind all joints

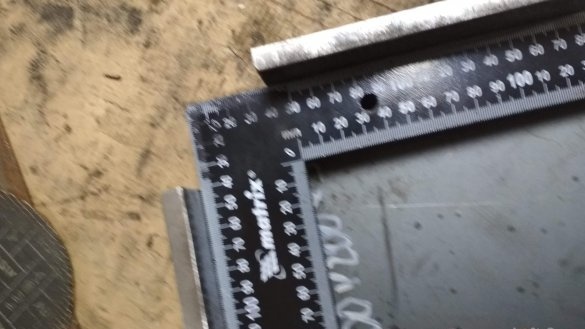

Particular attention should be paid to the seam between the stop and the base, there should be a right angle or you can even slightly drown the metal so that the rectangular part rests on both walls without a gap

Next, we assemble all the details in one common design

We try to clamp the parts, in this example, pieces of the profile pipe

I am very pleased with the result, I made two of them at once.

if something is not clear from the photos, then the video is still described in detail

Good ideas and opportunities to bring them to life.