Hi everyone, this homemade will be useful for those who have a drilling machine. The most common problem with such machines is that the drills and other drilling tools become very hot when drilling thick workpieces. And overheating leads to damage to the drill, crown or other drill nozzle. To solve this problem, the author decided to make a special automatic cooling system. A special coolant is supplied to the drilling zone, which circulates in a circle.

In addition, the table is equipped with wheels, which allows it to be conveniently and easily moved together with the drilling machine. If the homemade product interested you, I suggest that you familiarize yourself with it in more detail.

Materials and tools used by the author:

Material List:

- profile pipes;

- Sheet steel;

- two wheels that can support a weight of at least 150 kg;

- ;

- automobile or similar;

- hoses, adapters, etc .;

- a magnet (from a speaker or the like);

- screws;

- 24V power supply and cable for 220V;

- concentrated coolant;

- paint.

Tool List:

- drilling machine;

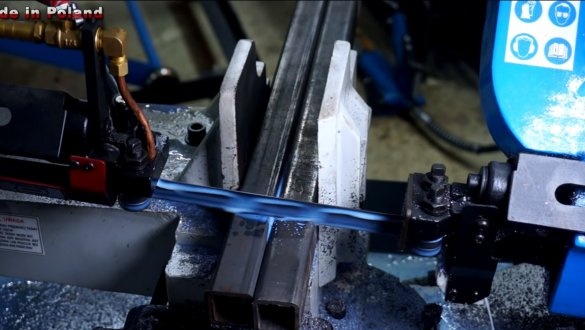

- tape cutting saw;

- grinder;

- plasma cutter;

- welding machine;

- lathe;

- vernier caliper, tape measure marker, etc.

Homemade manufacturing process:

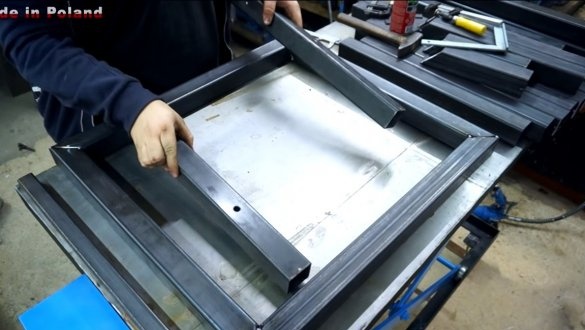

Step one. We make a table frame

We make the table frame from profile pipes, taking into account the weight of the machine and its dimensions. The design of the table is such that the author decided to install a ready-made drawer for drills and other tools in the table. Also inside will be a container with coolant. We cut the workpieces, and then we weld everything thoroughly.

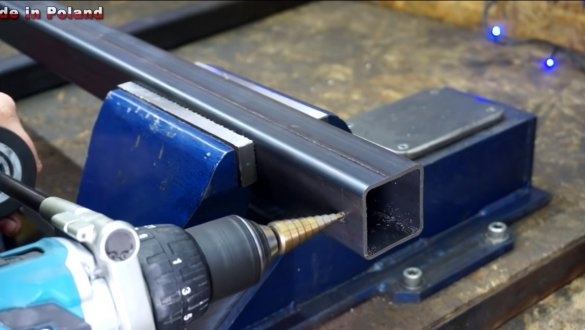

Step Two Base

The base of the table has a rather interesting design, there is a movable frame on which an axle with wheels is fixed. Turning or unscrewing the screw, we raise the table on the wheels or vice versa, fix it on the floor. The axle with wheels is fixed clearly in the center of the table frame, so that the whole table can be easily moved.

We weld a “fork” for the axle with wheels, it will be attached to the table frame through the steel axis, in which holes for screws are drilled. On the other hand, this entire structure will rest on a bolt wrapped in a nut welded to the table frame. With this bolt we will lower or raise the table on the wheels.

As for the wheels, you need to grind the axle for them, the author made it on a lathe. We fix the axis using strong ears from the steel corner. After that, our table will be able to ride.

Step Three Countertop

The table top is made of sheet metal, best of stainless steel, which can be welded. The countertops should have sides that will not allow coolant to flow out. The author bent these sides, after making the cuts with the grinder in the right places, and then we grab the whole thing with welding.

On the countertop, we organize the drain by welding a piece of steel pipe. This point should be the lowest for liquid to flow here. We make a recess by heating this area with a burner and working with a hammer. We also drill holes for the hinge tube and the mounting of the drilling machine.

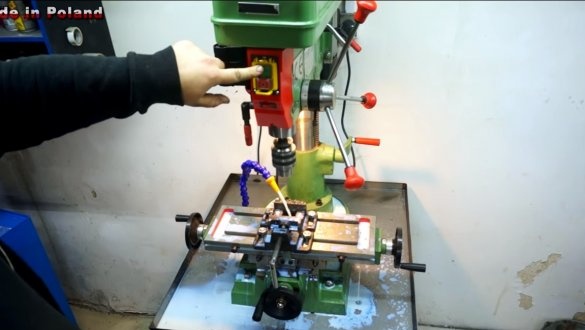

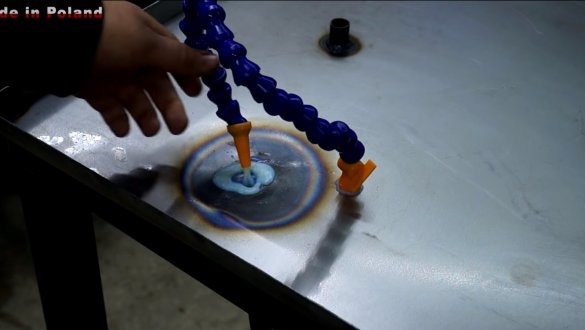

Step Four Cooling system installation

The cooling system is a tank that the author has welded from sheet steel, a pump is installed inside the tank. A pump from a car or the like is suitable, it is important that it has a rough filter on it. We install the pump from the bottom of the tank at a certain distance so that it does not suck in the chips. By the way, to capture the chips, the author installed a magnet on the bottom of the tank. But it will not help when drilling non-ferrous metals or even non-metals, so consider filtering.

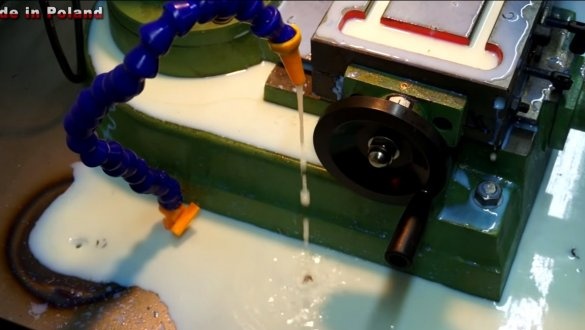

We attach the capacity to the frame and connect the supply hose to the countertop, it connects here. We connect another hose to the drain, the diameter here should be larger so that the hose does not clog with chips.

After this, we prepare and fill in the coolant, for this we need concentrated coolant for machine tools and water. When mixing substances in the right proportions, a white emulsion is obtained. Pour enough fluid to reach the pump.

We install a switch in the frame of the table, with which we can turn off the pump if necessary.

Step Five Sheathing

The table frame can be trimmed to hide all the insides. Here we need sheet steel or even plywood. It is better to choose a material easier, since the machine together with the table will weigh a lot.

In conclusion, it is useful to paint the table so that the metal does not rust, and this will occur intensively due to the coolant. That is why the countertop is best made of stainless steel.

Step Six Final assembly

We install a drilling machine on the countertop, securely fasten it with bolts and nuts. After the machine switch, where the voltage is supplied to the engine, we will need to connect another cable, it is needed to supply voltage to the 24V power supply, which will power the pump. As a result, when the machine is turned on, the pump will automatically turn on. Of course, if desired, this automation is easily turned off thanks to a switch built into the table earlier.

The machine is ready, you can try it! There is a faucet on the hinge tube that allows you to control the pressure of the coolant. As an experiment, the author decided to drill a profile pipe with a crown. Now this is done quite easily, you do not even need to lubricate anything, since there is already a lubricant in the coolant. After drilling, the author freely grasped the crown with his hand; it did not heat up as in the usual “dry” drilling.

As a result, the home-made turned out to be quite successful and useful, I hope you liked the project. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!