In this article, the YouTube author of TheDacchio will tell you how easy it is to copy a cutting tool holder for a lathe if the old one is damaged or loose.

Materials

- Steel bar

- Stud, nut, washer M8

- M6 bolts

- Thread lock.

Instruments, used by the author.

- Drilling machine with coordinate table

- Cutters for metal

- Drills, taps

- Lathe

- Allen key

- Pliers

- Cutters

- Sandpaper

- Vise, vernier caliper, hammer, core.

Manufacturing process.

So, the author decided to copy the tool holder.

To do this, he picked up a steel bar with dimensions of 77X40X27.5 mm.

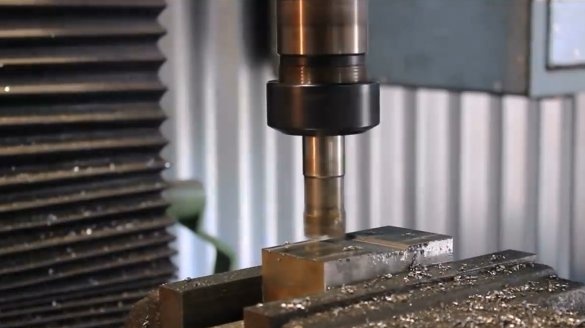

First of all, he sets the workpiece in the coordinate table, and mills all sides, adjusting the size to the original.

Then mills the transverse groove, referring to the dimensions.

Replacing the cutter with a more accurate one, adjusts the size of the groove.

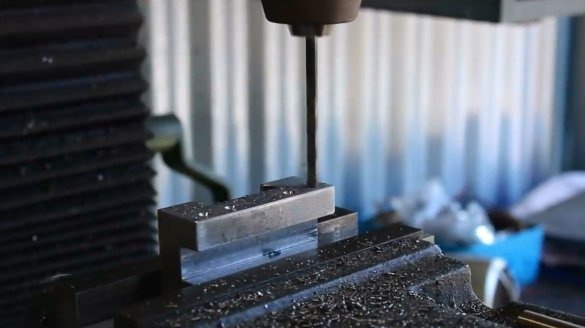

The next step is to grind the edges at an angle, creating a dovetail mount.

It fixes the workpiece in a vice, polishes the edges with a small diamond file and sandpaper.

Now cuts a longitudinal groove on the other side of the workpiece.

Having cleared the chips from the workplace, outlines four points for the mounting bolts.

Then he drills holes.

Installs a tap in the cartridge, cuts the thread.

Also drills a hole for an adjusting bolt.

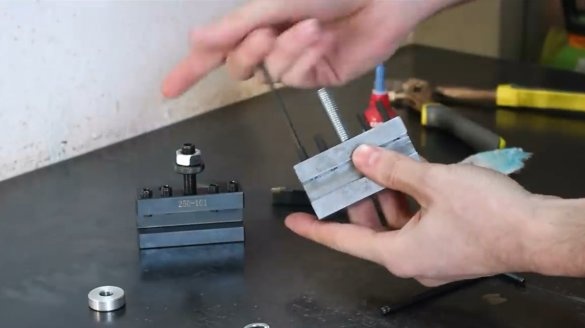

Almost perfect resemblance to the factory holder.

Using the thread lock, screw the stud, then, wrapping a rag, clamps it.

Installs clamping bolts, screw them in with a hex wrench.

Screws the support nut, tightens with a lock nut.

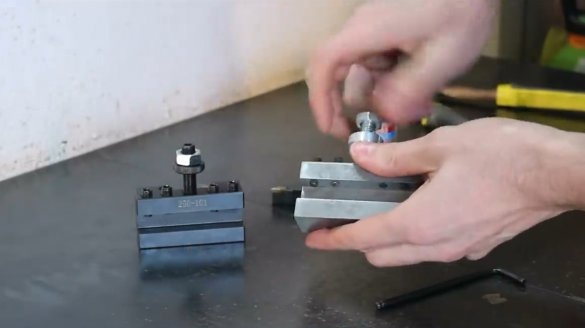

Puts device to its rightful place on the machine, and adjusts.

The machine has earned like new!

There was a small touch - it is necessary to write what has been done in Italy =). Flat core and hammer - to help.

Thanks to the author for a simple but necessary fixture for a lathe!

All good mood, good luck, and interesting ideas!