Hello everyone, today we will figure out how to make an electric scooter. For these purposes, the author used a ready-made kit with an engine, controller, control knob and other details. Such kits are sold in China, they come in different capacities, from several hundred watts to several kilowatts. Perhaps these are the most expensive parts that were used for the scooter, everything else is assembled from metal. The frame is welded from profile pipes, and the battery compartment is made of sheet steel.

At the author in homemade A 350-watt motor is used that operates on 36V. This power is enough to accelerate the Indian to 40 km / h, the scooter pulls even two Indians, but, of course, not at that speed. So, if the project interests you, I propose to study it in more detail.

Materials and tools used by the author:

Material List:

- (36V / 350 Watts);

- bicycle wheels with disc brakes;

- front fork;

- profile pipes;

- batteries;

- Sheet steel;

- paint, plastic screeds and other little things.

Tool List:

- Miter saw;

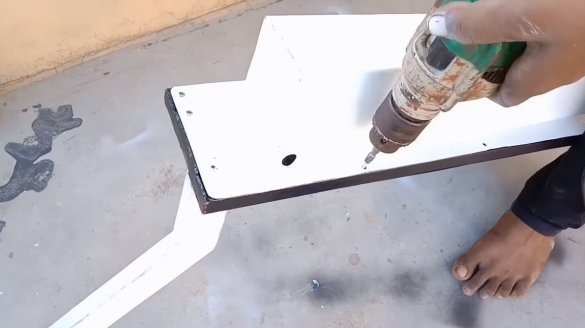

- drill;

- bending machine (if any);

- welding machine;

- grinder;

- marker, squares, etc.

Homemade manufacturing process:

Step one. Weld the frame

First we weld the frame, for this we cut profile pipes with a miter saw. Well, then the whole thing is well welded at right angles, here it is convenient to use magnetic squares. We clean the welds with a grinder so that everything looks neat.

Step Two Rear fork

Let's make the rear fork for the scooter, here we need steel corners. We cut them and weld, as a result, a design in the form of the letter "P" should be obtained. After welding, we cut off the excess to give the plug the desired shape. Well, then we drill holes and make cuts for installing the rear wheel. We securely weld the plug to the frame.

Step Three Front fork

We weld the front of the frame for installing the plug, everything here is also made of profile pipes.The author’s plug is already ready, after its installation we have a ready-made scooter, however, so far without an engine.

Step Four Battery tray

We make for the scooter a pallet in which the batteries will be located, as well as a controller for the engine. We cut the blank from sheet metal, preferably from aluminum, so the scooter will be much easier, but the structure cannot be welded.

To give the design the desired shape, the author uses a bending machine. To bend metal manually, you can make small cuts with a grinder, steel will bend clearly along the line of cuts. Well, then this whole thing will remain well cooked. Do not forget to also make a cover for the battery compartment.

Step Five Final touches with frame.

At the end, we install the footboard, since without it the scooter will constantly fall, and it weighs a lot.

We weld a bracket for installing a brake caliper to the rear fork. And also we make a damper for steering.

Step Six Painting and assembly

We clean metal surfaces well, now they can be painted. After painting, the scooter will look “like from the factory”, and even the metal will not rust.

That's all, you can assemble a scooter. If desired, you can glue the frame and rim as a decor.

We install the engine, securely fasten it with bolts and nuts to the frame. We hide the controller in a pallet, we install batteries here, the author has the most common ones. If the battery is assembled on lithium cells, the scooter will go much further and faster.

We install the speed control knob, we conduct all the wiring along the frame, fixing it with plastic ties. Do not forget to connect the brakes.

Seventh step. Test

You can test the scooter, the author starts off quite quickly, with a 350-watt engine the car accelerates to 40 km / h, which is more than enough for such a small scooter. The power of homemade is quite enough to ride a scooter together.

That's all, the project is over, good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!