The master is fond of metalworking, in particular the manufacture of knives, and for comfortable work he needs an anvil. The prices for such a product, even used ones, are high and the master decided to make the anvil on his own.

Tools and materials:

-Metal blocks;

-Welding machine;

- Band saw;

-USHM;

Reciprocating saw;

-Rule;

-Marker;

Step One: Material Selection

For the anvil, the master uses two types of steel: mild 1018 CR, for the base and, hard S7, for the upper part (steel grades are given according to US standards).

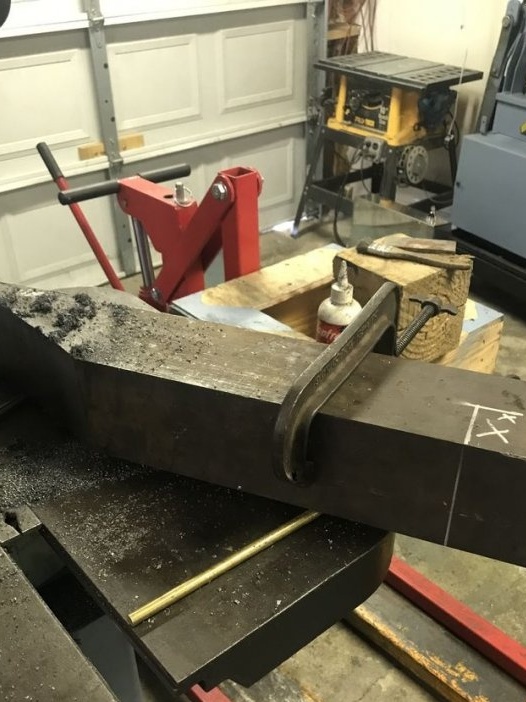

Step Two: Cutting

Marks up metal blocks.

Slices metal forming parts of the anvil.

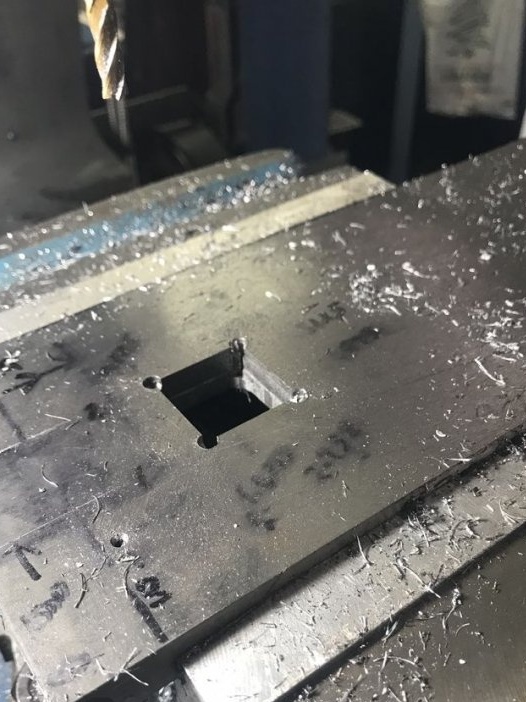

On the upper platform makes a square hole.

Step Three: Grinding

Now you need to grind the parts of the anvil.

Step Four: Welding

After processing the parts of the anvil, the master welds them together.

Step Five: Top Plate

Now you need to add the top plate of tool steel S7. The master also made a square hole in the plate, and before welding it will be necessary to combine it with the lower hole. In order to weld a plate, the master first preheats it in a gas oven. After welding, you need to warm up the weld so that it cools down slowly and does not crack. The master heats it with a gas burner.

Step Six: Painting

After the seam has cooled, the master polishes and paints the anvil.

The anvil is ready.