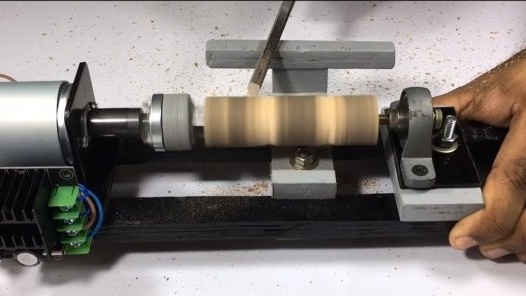

Hello fans to craft, if you have to make small wood products, this homemade just for you. Today we will look at how to make a small lathe on a 775 engine. Such a machine is almost silent, you can even work in it in an apartment, and you can power it with a battery, because the engine runs on 12-24V. The author of the homemade product provided for the installation of a speed controller, so that you can select the mode you need. The machine copes with the task without any problems, the author as an experiment made a handle for a tool from a piece of a stick. The materials and the assembly process are accessible even to a beginner, so if you need such homemade work, I suggest studying the project in more detail!

Materials and tools used by the author:

Material List:

- plywood;

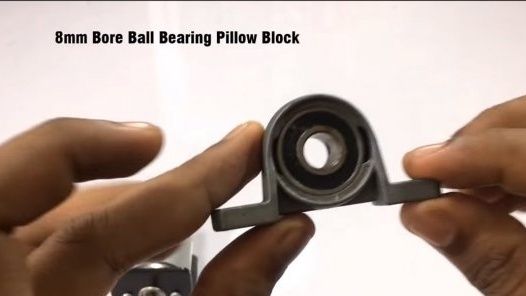

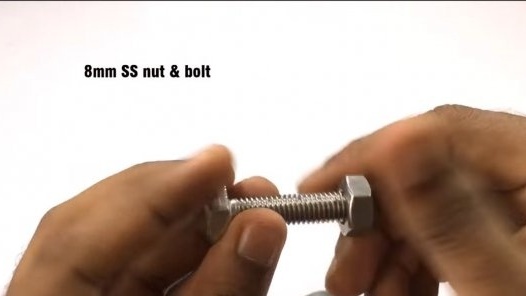

- a bearing in the housing and a bolt with a nut (for the tailstock);

- two nails, screws with nuts and washers (for the headstock);

- ;

- an arm for the engine 775;

- ;

-;

- bolts, nuts, screws and other little things.

Tool List:

- a circular saw or other tool for cutting plywood;

- drill;

- soldering iron;

- carpentry glue;

- screwdriver;

- hammer;

- pliers.

Lathe manufacturing process:

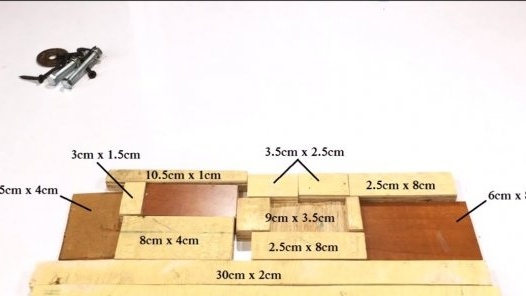

Step one. Cut the details

The first thing you have to do all the necessary calculations and cut the desired number of blanks. In order not to think for himself, the author has already presented in the photo what parts should be and what sizes they have. Of course, evenly cut the plywood is most convenient on a circular, but if this is not, you can handle a hacksaw or a jigsaw.

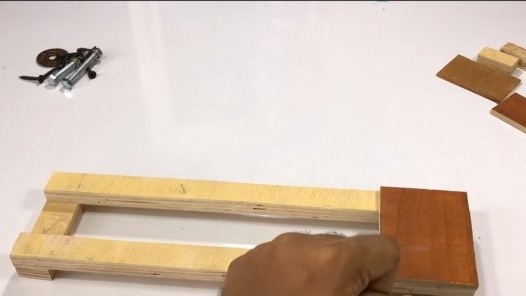

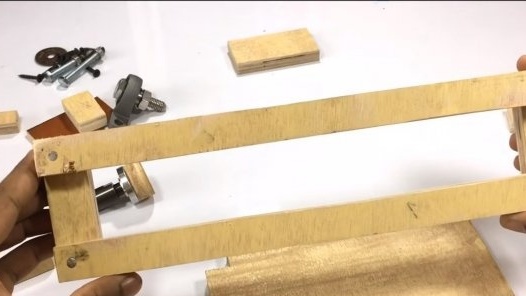

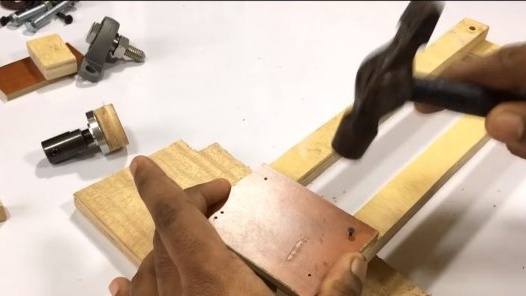

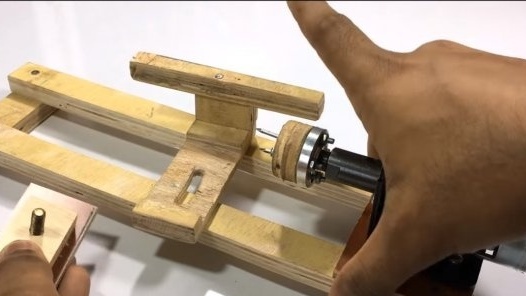

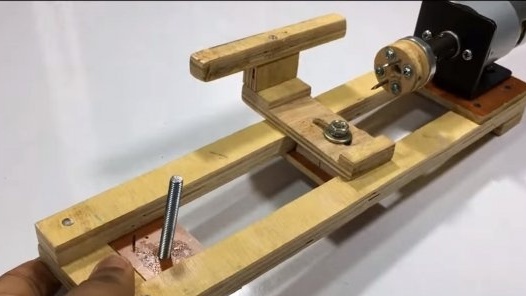

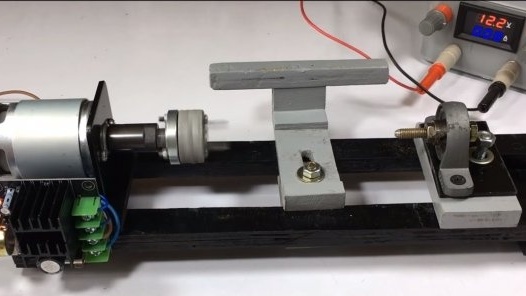

Step Two Bed assembly

We assemble the bed, here we need a drill, drill holes and collect everything on nails, and for reliability it is recommended to use carpentry glue.

As for the movable platforms, on which the tailstock and emphasis are mounted, we glue them on the carpentry glue, and then these platforms on the bed will be pulled together with a bolt and nut, so we drill holes for these purposes.

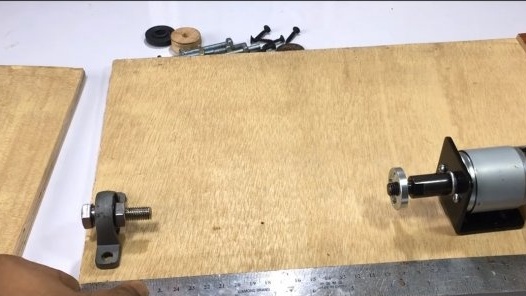

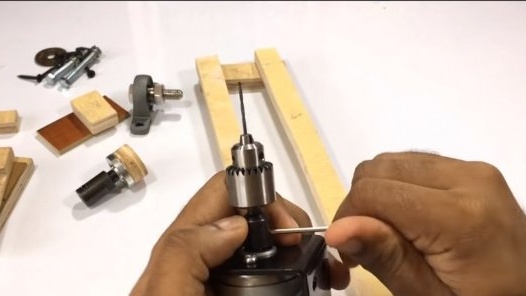

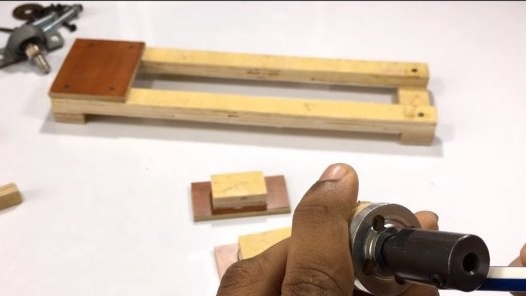

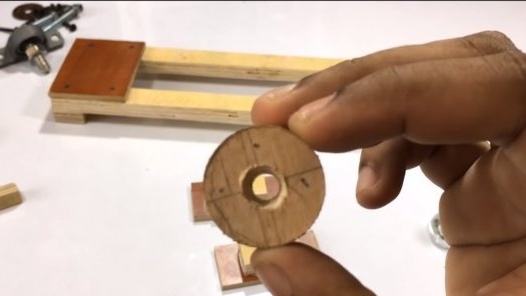

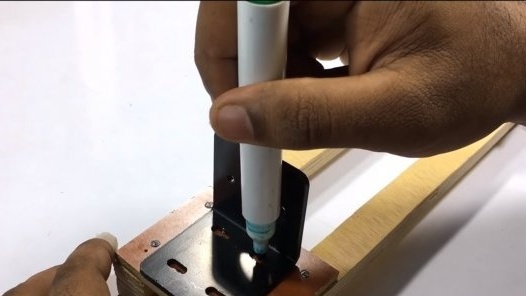

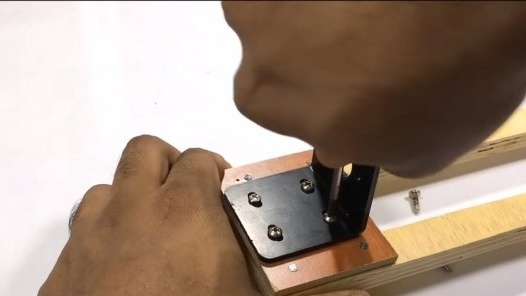

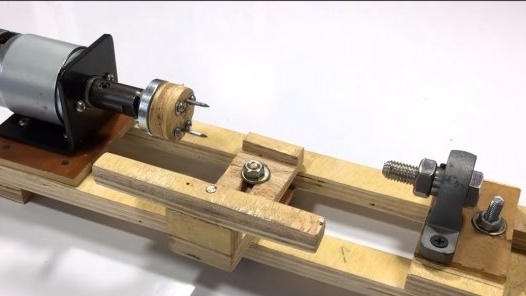

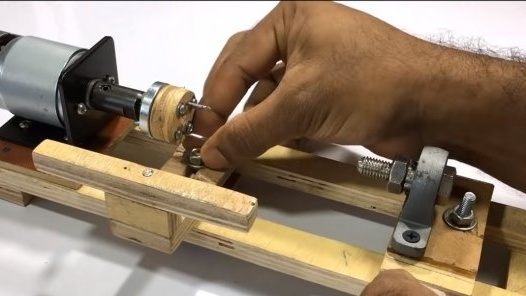

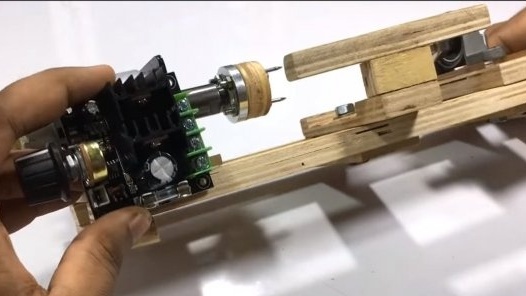

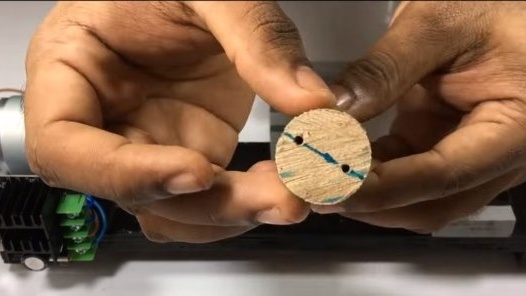

Step Three Installing the headstock and engine

The headstock is mounted on the motor shaft, for its manufacture we need the “Bulgarian” adapter, which is mounted on the motor shaft. To this adapter you need to screw a round part from plywood, this will be the headstock. To fix the product, two nails are installed in the headstock. For fastening parts from plywood, we use screws with nuts. Everything should be reliable here.

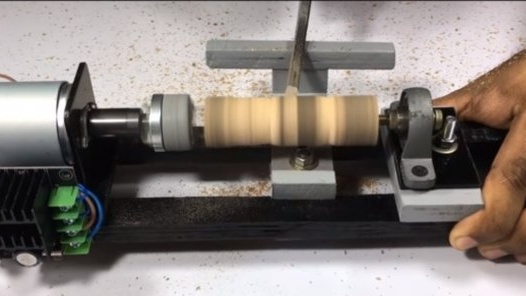

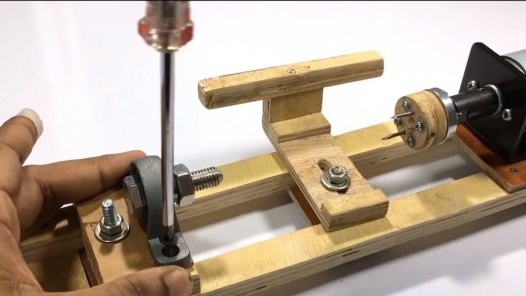

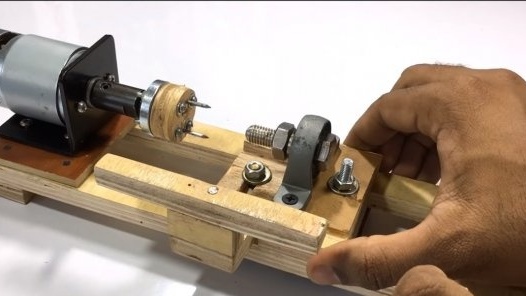

Step Four Tailstock and stop

We put the emphasis and the tailstock in its place, as the tailstock, the author used ball bearing in the housing, on which he fixed the bolt with nut. The bolt can be sharpened a little. Now the machine is ready, it remains only to paint it.

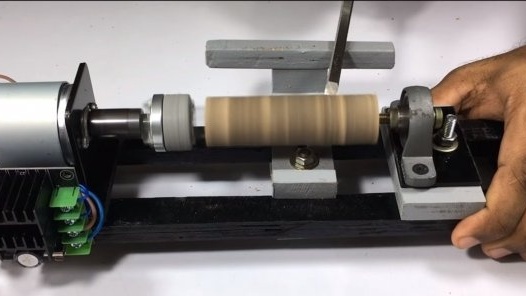

Since the revolutions of the 775 engine will be very large, here we will definitely need a speed regulator. It is important that the regulator not only can reduce revolutions, but at the same time can maintain high torque, which is very important for a lathe.

That's all, our stanochka is ready; As an experiment, the author has carved a pen from a piece of a branch, it can now be installed on a file, a screwdriver, and so on. The project can be considered successfully completed, I hope you liked it, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!