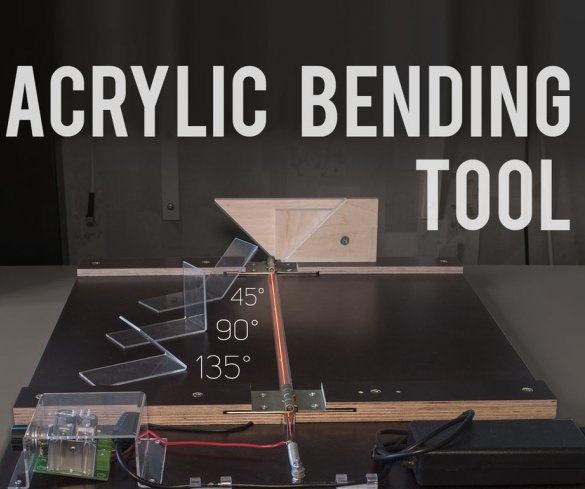

With this bending machine, you can easily perform accurate acrylic bends at 45, 90 and 135 degrees. The device has a built-in 90 W power supply from an old laptop and a built-in power control unit.

Tools and materials:

clamps;

- Electric jigsaw;

-A screwdriver;

-Manual frezer;

-Roulette;

-Gon;

-Knife;

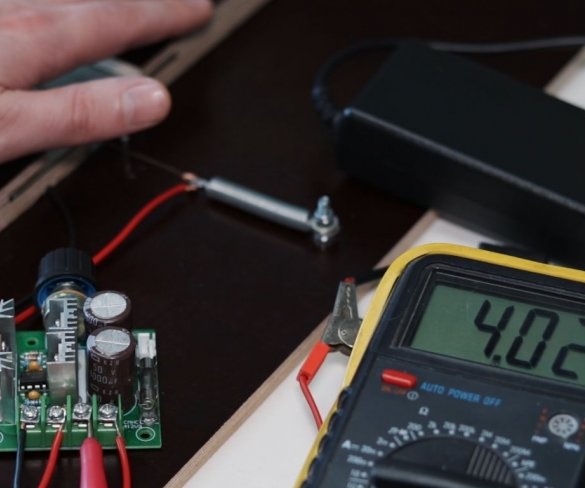

-Digital multimeter;

-Soldering accessories;

MDF;

-Acrylic;

-Aluminum profile;

-Fasteners;

-Spring;

- Loops;

-Wire;

- Power supply 19V 4.74A 90W;

Step One: Trimming MDF

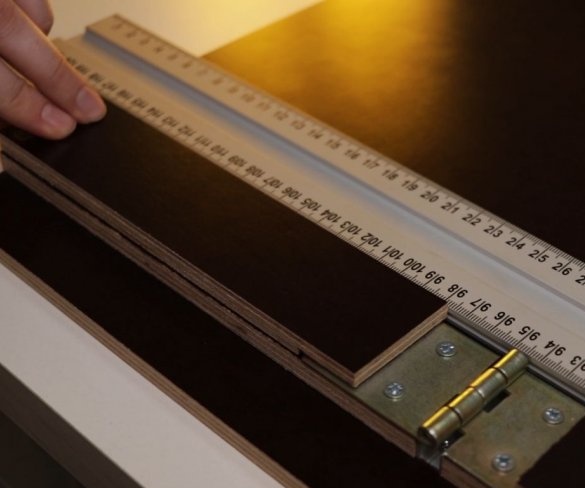

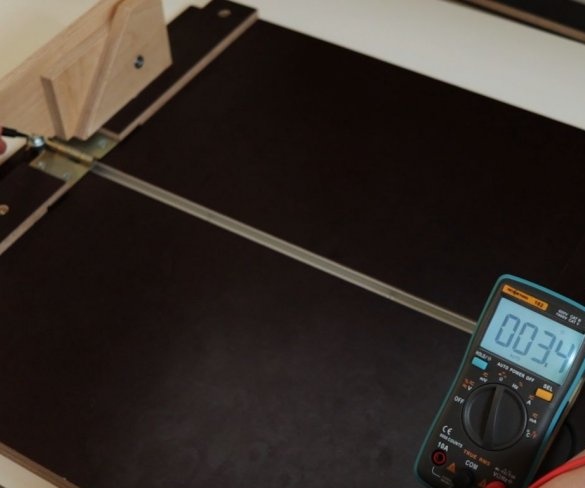

First, the master cuts the MDF sheets. One sheet is the base 45 * 60 cm, two sheets 45 * 22 cm, and four 19.5 x 4.5 cm. The length of the aluminum profile is 45 cm. After trimming the MDF, the master first estimates the location of the parts of the device.

Step Two: Groove

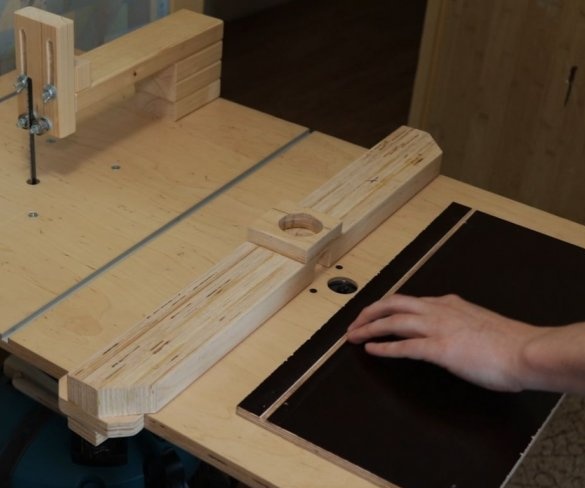

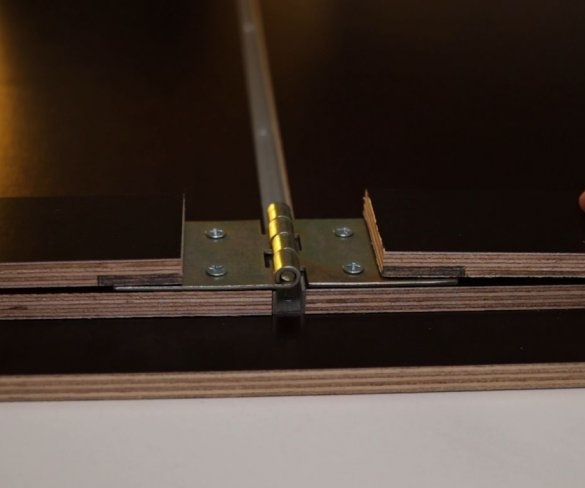

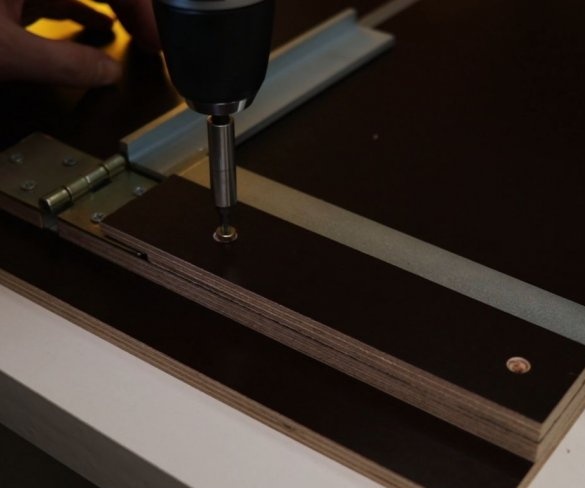

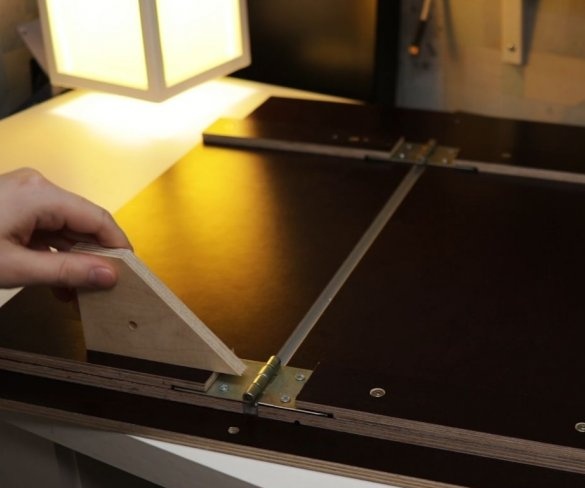

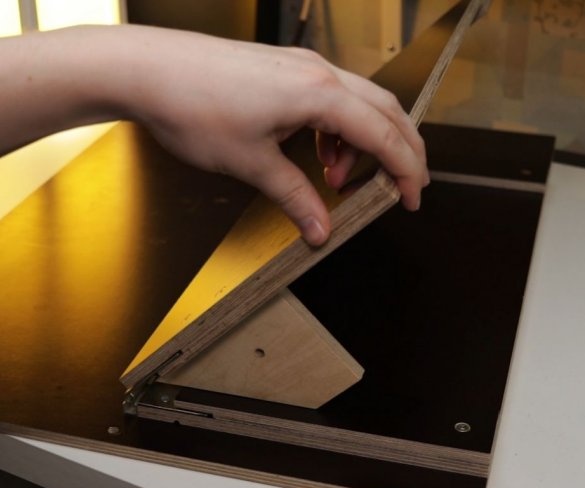

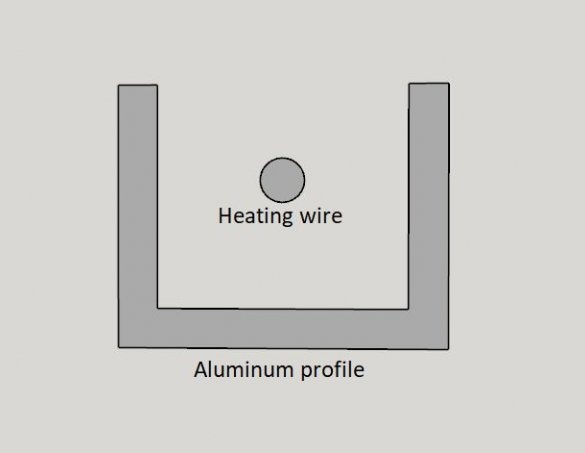

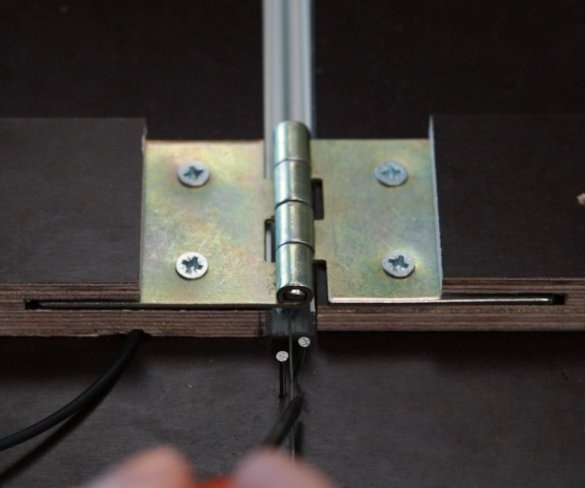

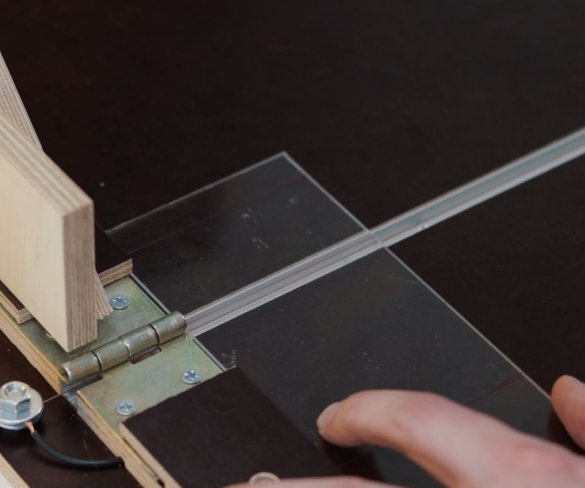

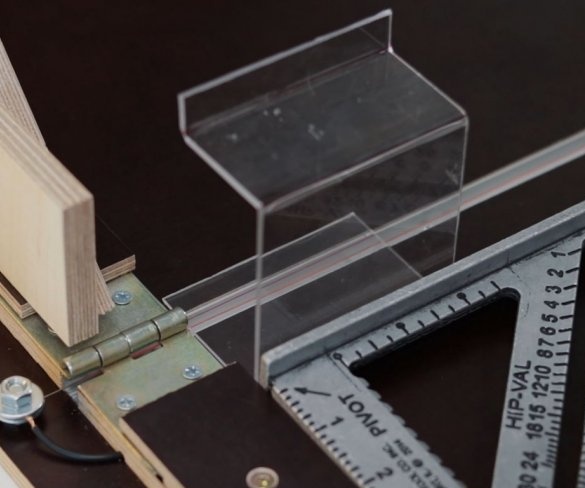

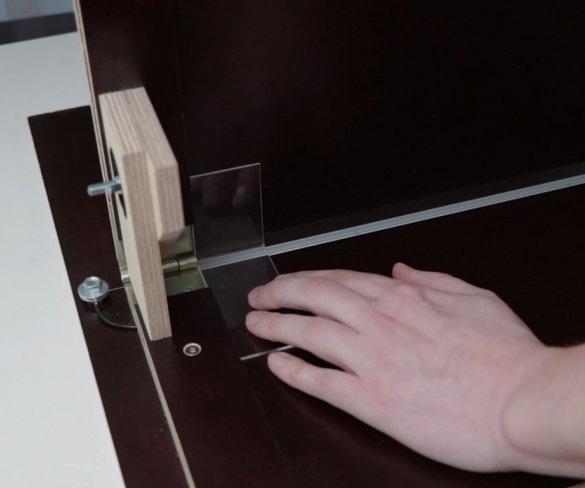

In one sheet MDF 45 * 22 cm makes a longitudinal groove for the wire. Then screw this sheet to the base. Screws the aluminum profile. By means of loops connects two 22 cm preparations. Now, on the base, one workpiece is fixed tightly, the second moves on loops.

Step Three: Guides

Now you need to fix the guides. On the blanks, material is selected for the loops.

Secures the guides.

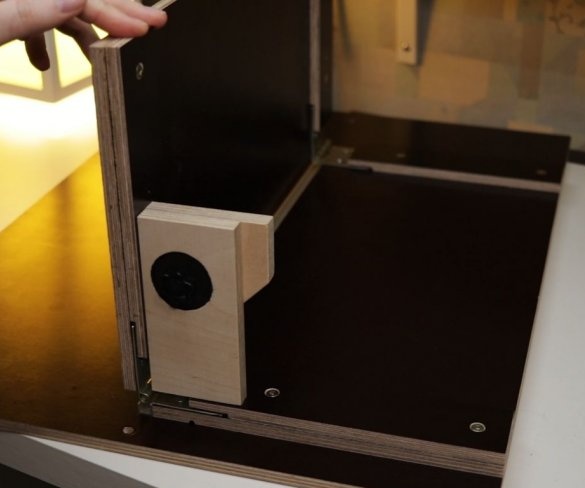

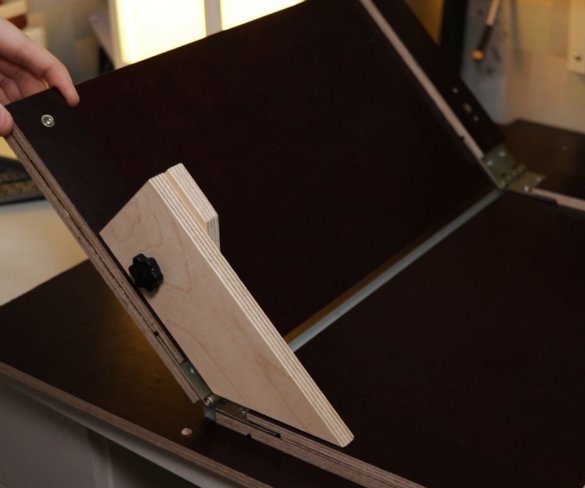

Step Four: Stops

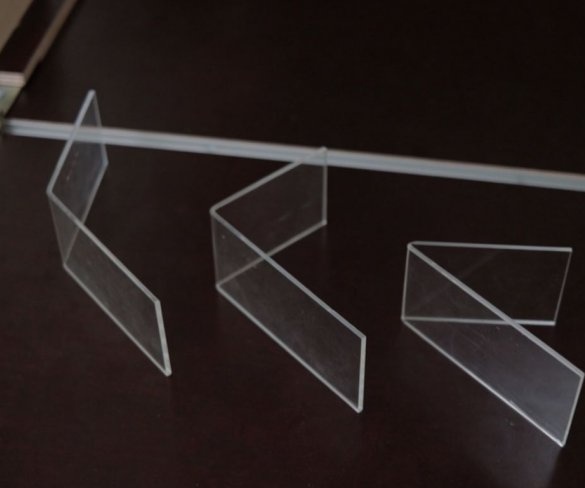

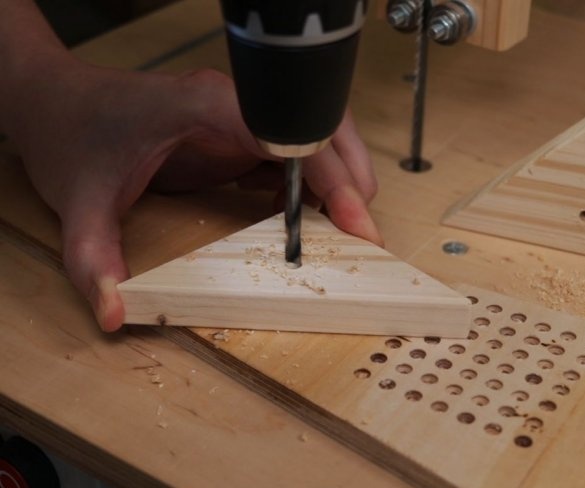

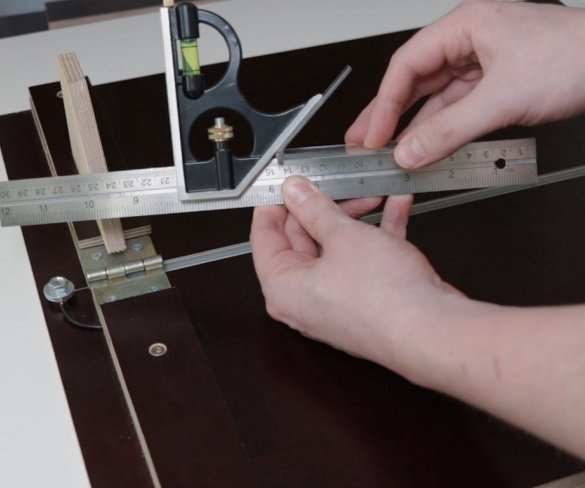

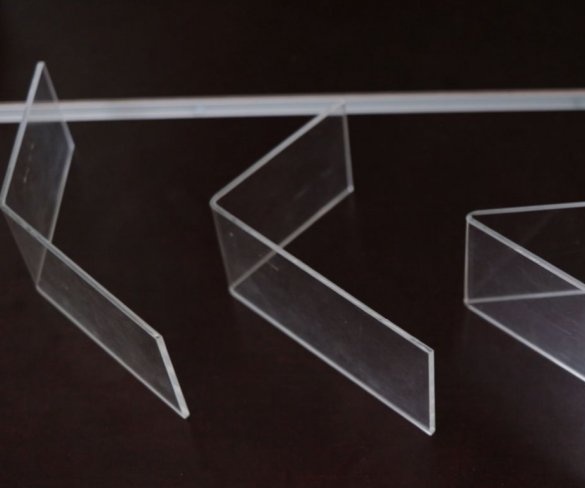

It cuts several stops at 135, 90 and 45 degrees.

Step Five: Nichrome Wire

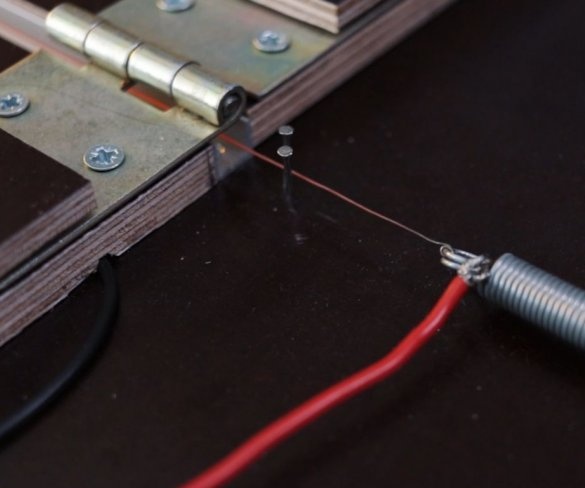

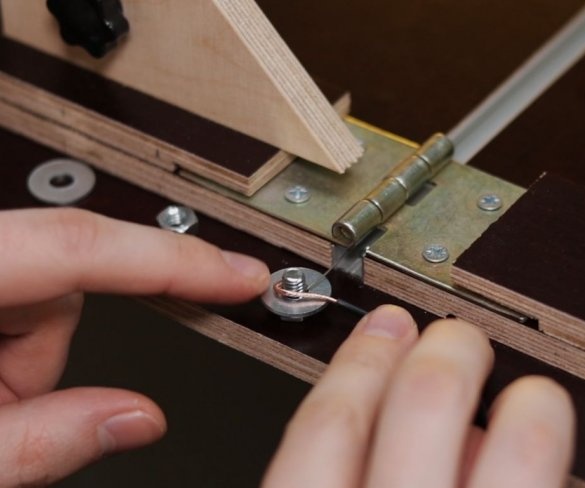

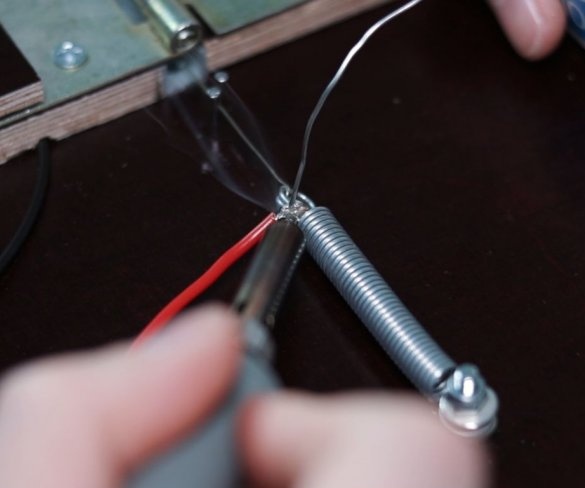

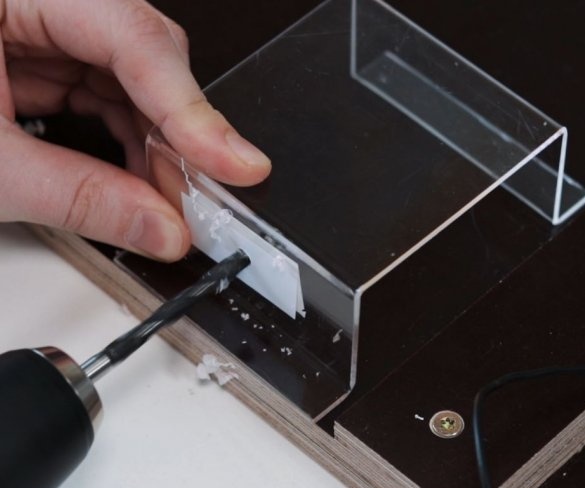

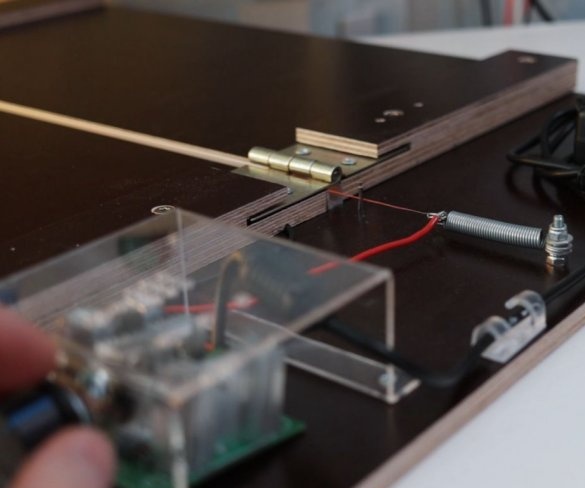

Now you need to fix the nichrome wire. On the base, on the left and right sides of the profile, drills two holes.

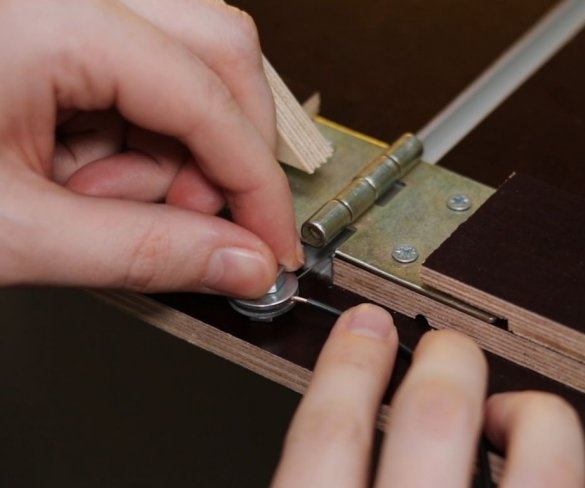

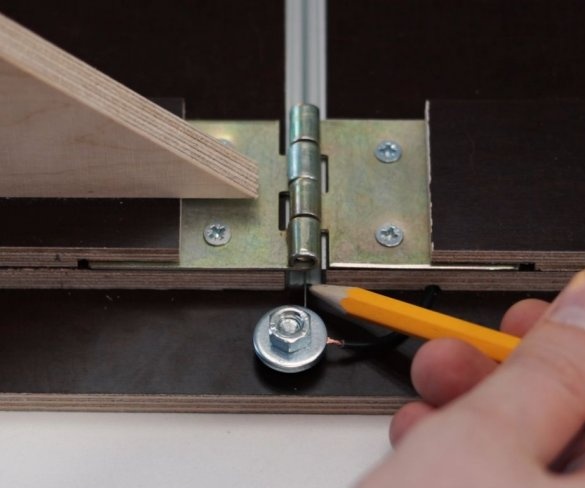

Installs bolts in the holes. Connects wires and nichrome wire to bolts. On the one hand, the wire is attached to the bolt through a spring. It is important that the wire passes exactly in the middle of the aluminum profile, without touching its walls.

For safety reasons, the master hammer two nails on both sides of the wire. This precaution will prevent the wire from touching the profile.

The master solders the wire to the spring.

Step Six: Power

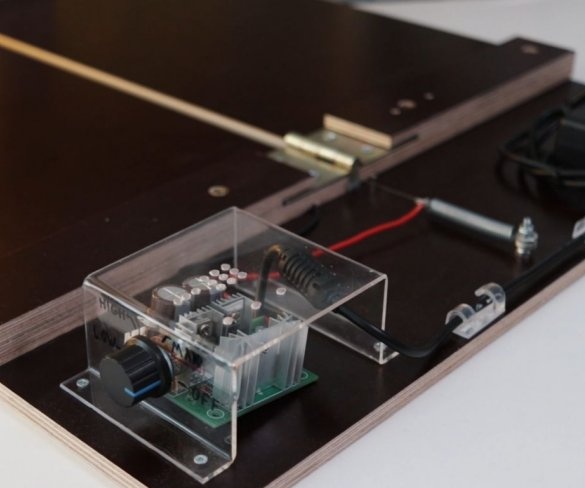

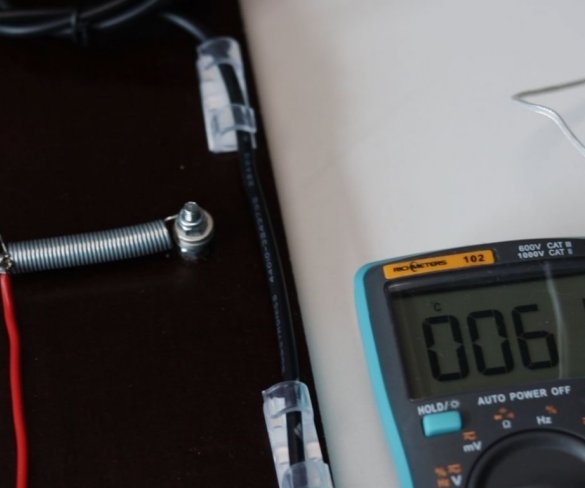

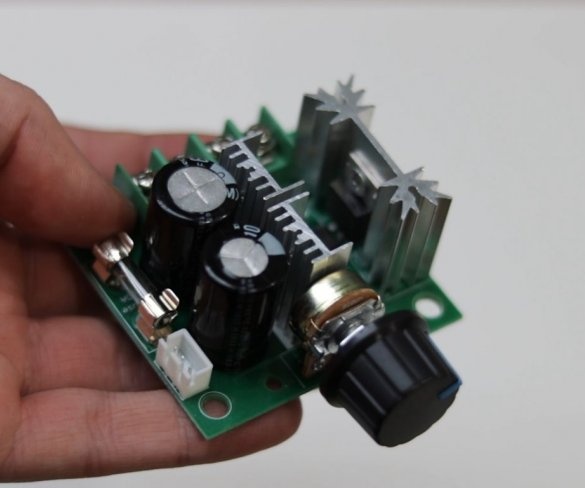

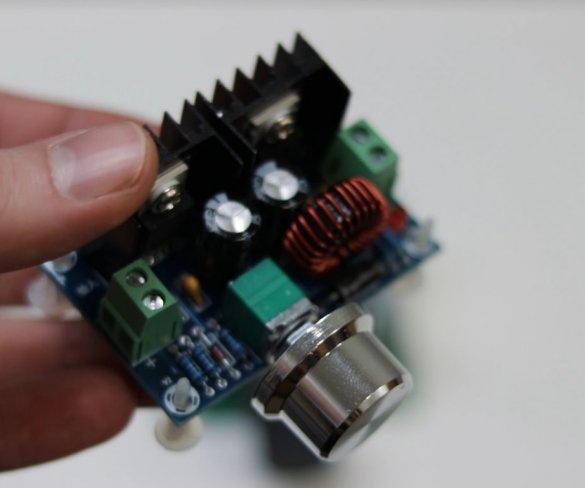

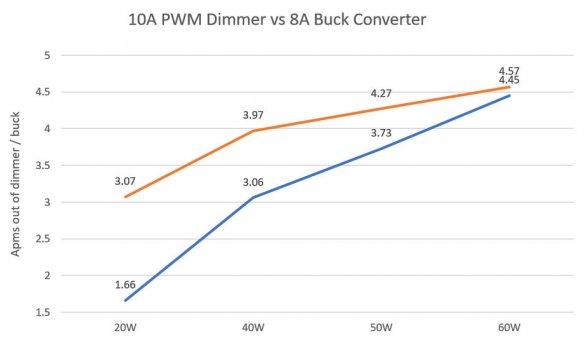

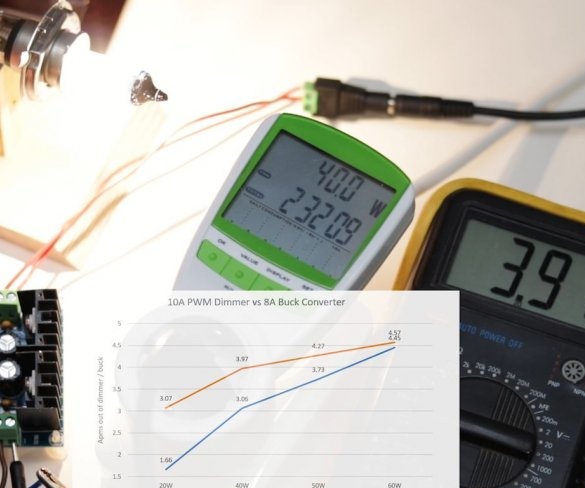

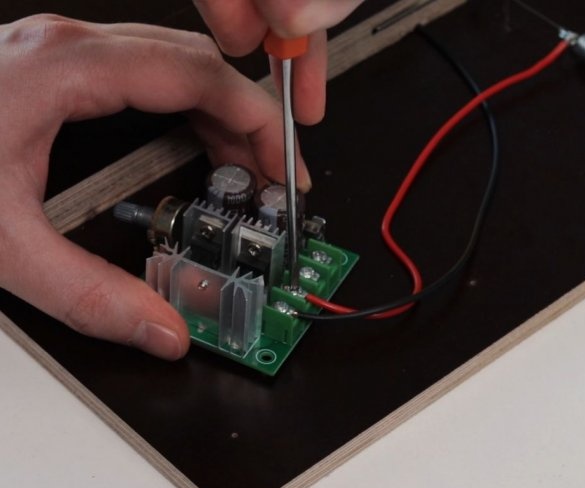

For power, the master uses 19 V, 4.74 A, 90 W laptop power supply. You cannot directly connect such a unit. The master chooses between a 10A PWM controller and an 8A voltage regulator.

After a series of tests, the master came to the conclusion that it is better to use a PWM controller.

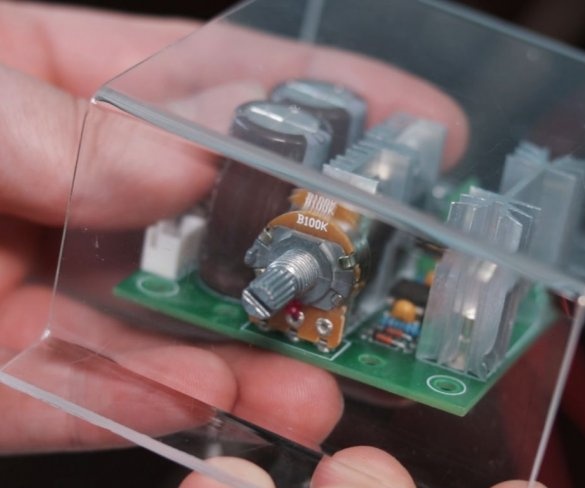

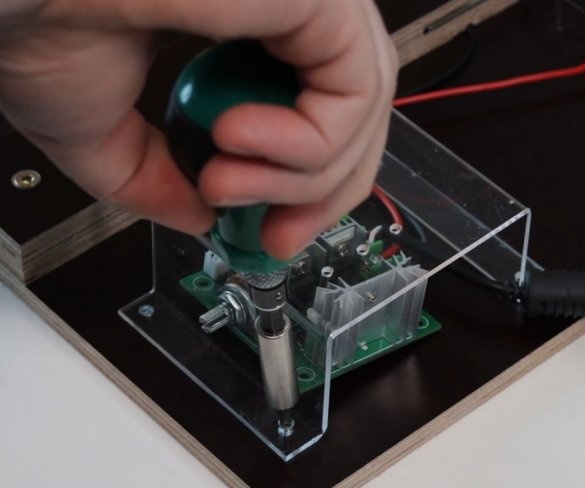

The wizard temporarily connects the controller.Cut and bend acrylic. The protective cover for the controller is ready.

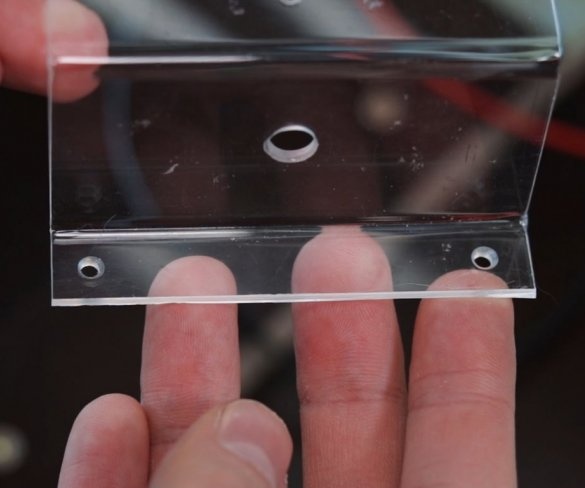

In the lid, holes are drilled for mounting, ventilation, and for the adjustment knob.

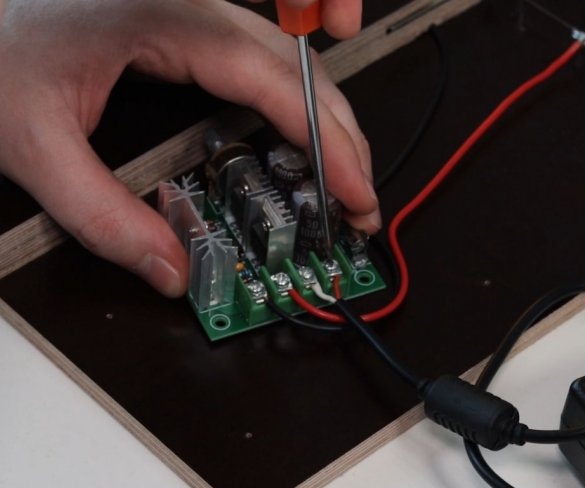

Fixes PWM. Connects wires. Screws on the lid.

It connects the energy meter and marks the operating modes on the cover: off (OFF), 60 W (LOW), 90 W (HIGH) and maximum value (MAX). It is enough from 0-90 W to work, in order to avoid breakage, the master does not advise setting the value to the maximum with a power supply with similar characteristics.

The acrylic bending machine is ready. The author made it possible to bend acrylic at angles of 45, 90 and 135 degrees, but if necessary, any angle can be made.

The whole process of manufacturing the device can be seen in the video.