The table is the most integral part of our interior. It’s hard to imagine any home, office, and so on without this necessary of furniture. After all, whatever one may say, it is at the table that we spend a huge part of our daily time: at the table we eat, work, we invite guests to the table, sign important papers, and conduct negotiations. Like any other thing, the table has its own very interesting history of appearance. An ordinary table is a board placed on 4 legs or on the goats. At such tables in ancient times princes and kings feasted, common people.

The first tables began to be made in Ancient Egypt. At the time of their occurrence, at the same time their classification is introduced - lunch and workers. It is to the Egyptians that we owe the appearance of this subject of our interior. With the development of writing, the very first writing tables also appeared, which at that time served not so much for writing as for storing writing objects on it - pens, ink, sharpening knives and scrolls. All tables at that time were either round or square in shape, there was no talk of any decorations. And only with the advent of the Renaissance, when the world, after a long time of stagnation and church rules began to return to beauty in everything, everything developed and flourished, tables began to be characterized by various forms of execution, from ordinary square to elongated, ellipsoidal shapes.

Decor began to appear, as to know demanded beautiful status things an indicator of their wealth and significance. The legs of the tables have also changed. It was at this time that unique in their beauty and forms appeared, decorated with ornate carvings and various inserts made of precious stones and metals. The number of legs also varied, from classic 4 to 1.

Nowadays, a table is an interesting and original piece of furniture, diverse in its form and category of purpose.

It is about such a table that will be discussed in this article, authored by the owner of the YouTube channel DESIGNER'S DIARY.

For the manufacture of this product it took several sheets of plywood, drill or screwdriver, forstner drill, jigsaw, milling machine.

Step 1.

To begin with, the author makes a template from thin plywood, having previously drawn a sketch on graph paper and determined the size. The pattern of legs is transferred to the plywood. The corners are rounded off with a Forstner drill on both sides to get a good hole. Right angles are cut with a clerical knife to prevent the fibers from breaking up when sawing.

Step 2

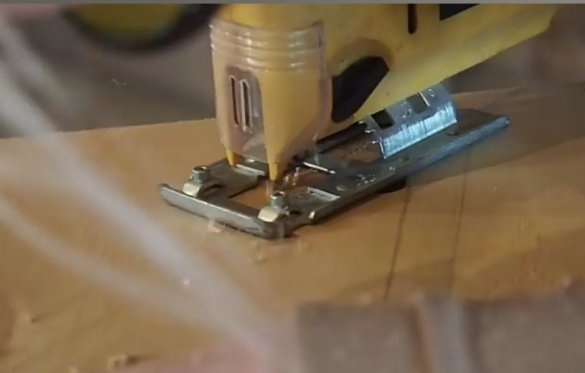

Using the template, the author transfers the drawing of the legs to the main plywood blank, carefully drawing all the details. The same actions that were carried out on the template are carried out on the main workpiece. The leg of the table is cut out.

Step 3

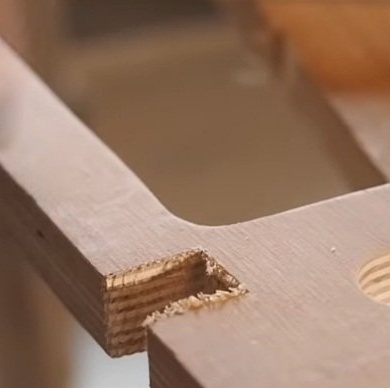

We attach a template to the finished part using double-sided tape. It must be firmly fixed to the base, otherwise when milling it can fly off and the cutter will choose the excess, which we absolutely do not need. Makes according to the template on one side, after turning on the other, thereby achieving greater smoothness of the processed faces. Further, when the details are processed, the author cuts out the grooves for connecting the legs together. This is done with a jigsaw, and the final revision is carried out by a cutter, which removes completely all the excess.

Step 4

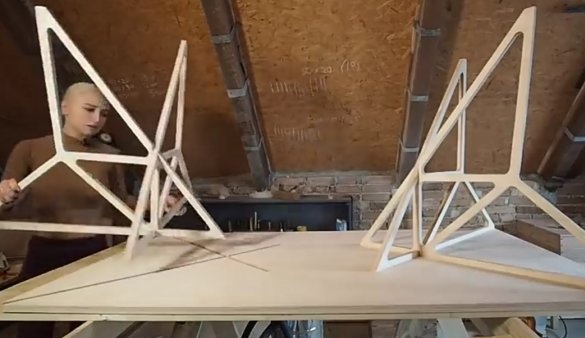

Next, places are prepared for attaching the legs to the countertop. Legs are applied to the inside of the countertop and mark the places where they will be installed. Further, according to the marked out, the grooves are selected by the milling machine, the width of which is equal to the width of the thickness of the plywood of the legs. After all the fibers remaining after milling are removed with a cutter. Since the author did not indicate a specific method of securing the parts into a single whole, anyone who wants to reproduce the same design will independently choose the method of fastening, which will be more suitable in a particular case.

Step 5

The finished structure is well sanded and coated with a primer and varnish in several layers. This completes the manufacture of the dining table.

This is what a fully finished table looks like, which is completely made of plywood.