Hello lovers of seeds, I propose to consider useful homemade. Of course, the process of peeling seeds is a pleasure for many, but this process is harmful to teeth, digestion, and even after it there is a lot of garbage. The proposed homemade product will solve this problem, now the seeds will be peeled automatically. Homemade is quite easy to assemble and everything is assembled from available materials. You can power the device from the battery, so you can start the installation on the street so as not to litter in the room. However, if you have agriculture, the waste can be fed to animals. The machine is driven by a small gear motor, a similar one is possible. If you are interested in home-made, I propose to study the project in more detail!

Materials and tools used by the author:

Material List:

- (or similar);

- (preferably);

- plywood, MDF or other similar material;

- metal cans from under drinks;

- wire;

- self-tapping screws;

- a wooden round timber (a rolling stick for dough is suitable);

- switch, wires, power source;

- .

Tool List:

- glue gun;

- soldering iron;

- jigsaw;

- a hacksaw;

- drill;

- file (triangular and round);

- stationery knife.

The process of making a peeling machine:

Step one. Base and Racks

We make the base and racks, here we need plywood, MDF or other material, even fiberboard is suitable, the loads here will be minimal. Cut out the base and make markings for the holes. As for the racks, they will be needed to hold the separation sleeve and other parts. To install the separation sleeve in the racks, cut holes with a jigsaw or drill them with a crown.

Step Two Making a separation sleeve

We will make a dividing sleeve, in it the husk will be separated from the peeled seeds of the seeds. A sleeve is a pipe through which a fan blows air. Accordingly, the light husk of the seeds will be carried along with the air, and the grains will fall down into the hole made in the pipe.

We make the necessary pipe from a metal can from under drinks. From it you need to cut off the bottom and neck. It is important to leave the narrow parts of the can, they will work as stiffeners, preventing the pipe from jamming. We just grind the bottom and the neckline on sandpaper, then the necessary details will disappear later.

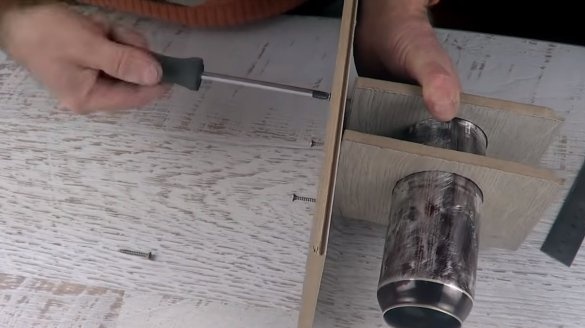

Then you can install the racks and the separation sleeve.Racks need to be screwed to the base with screws. We make markings, drill holes and wrap screws. In the final assembly, you can additionally lubricate the abutted surfaces with carpentry glue, everything will hold much stronger.

Step Three Millstone

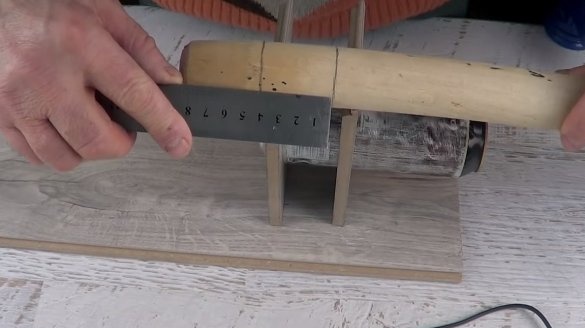

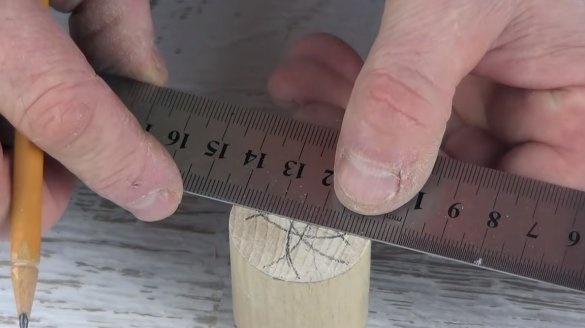

We will make millstones that will be responsible precisely for the process of peeling seeds. They are a wooden wheel with teeth. We begin to manufacture this wheel itself, we need a round timber made of wood, you can turn it yourself if you have a lathe, or you can use a drill as a lathe. The author used ready-made material - this is a stick for rolling dough. Cut off the desired piece, look for a hole and drill a hole.

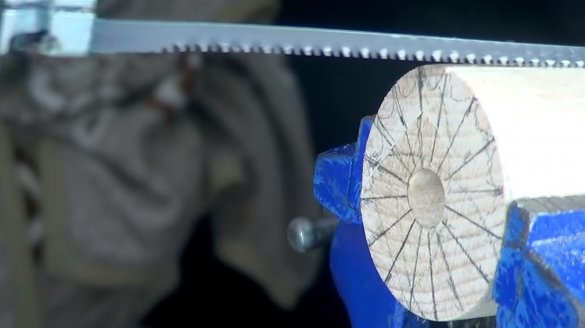

Next, you need to make the cloves, make the markup and get to work. First, we make cuts along the lines with a hacksaw for metal. Next, we arm ourselves with a triangular file and form the cloves. In the end, the author carries out the work with a small round file, reminiscent of the one used to sharpen the chainsaw chain. As a result, we get an excellent millstone. To install it on the motor shaft, we drill a hole across and wrap a self-tapping screw, and for reliability it is better to wrap a couple of such self-tapping screws, although the loads here are low.

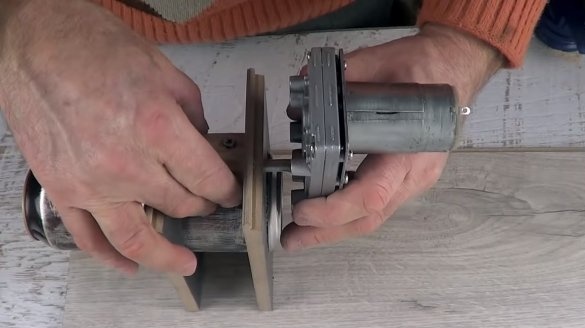

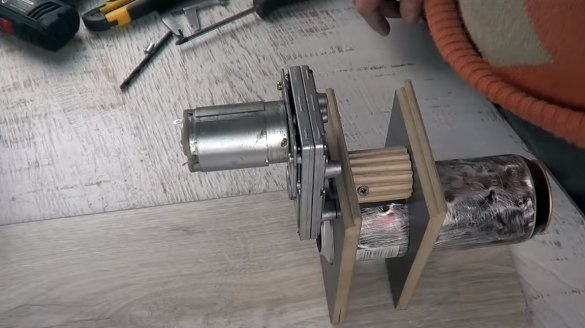

Step Four Engine installation

The engine can be installed in its place, and place it on one of the racks. We unscrew the rack, drill a hole for the engine shaft, as well as holes for mounting screws. That's all, fasten the motor, install the millstone and fasten the rack back to the base.

Step Five Delivery sleeve

We make a supply sleeve, for its manufacture we use the same material that was used to make the base and racks. We cut the parts with an electric jigsaw and assemble the structure on the screws. Sleeves also act as boundary walls for a millstone. The gap between the wheel should be small, otherwise small seeds will wake up in the peel, ideally, this parameter should be adjustable.

Step Six Pallet

We make a tray for the separation sleeve, peeled seeds will be poured into it. We make it from an aluminum can, cut off the desired strip and fasten it to the racks on a wire.

Seventh step. Fan

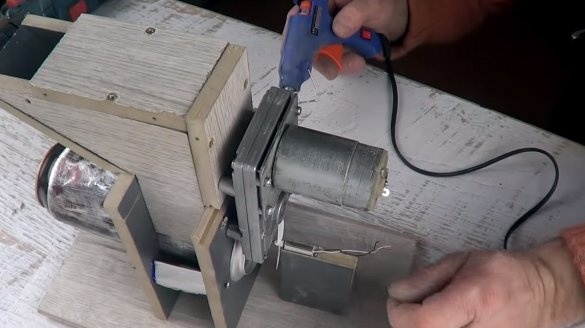

The design of the machine provides a fan to blow off the shell. We will need a small motor with a propeller. You can make a propeller yourself by cutting aluminum cans or metal cans from metal. And the motor is suitable even from an old mobile phone, but you can put more, for example, from a children's toy. For a motor we fasten a rack to the base, the author fastens his motor with hot glue to the rack, the engine here is used very small.

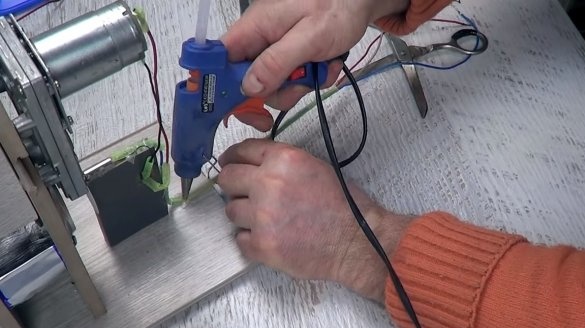

Step Eight. Final assembly and testing

We assemble the car, you need to solder the wires, and also install the switch. Do not forget that a small motor needs to be powered with a small voltage in the region of 3V, unlike the main one, which is powered by a voltage of 12-24V.

The machine is ready, you can start it, the author pours seeds from the cup into the feeding sleeve and at the exit we have already peeled grains. Of course, small crushed grains will also fly out of the separation sleeve, but this can be eliminated by reducing the fan speed, if you need these parts of the seeds.

On this project can be considered completed, I hope you liked the homemade product, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share with us your ideas and homemade products.