This fireplace was made for the interior of the new restaurant. It is made of 12mm hot rolled steel. Using such an outdoor fireplace will give the restaurant an atmosphere of warmth and coziness, and, when used in the hearth of flavors, will attract more visitors.

Tools and materials:

-A metal sheet;

-Welding machine;

-Ushm;

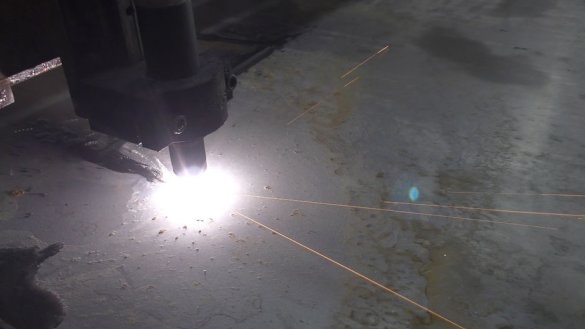

- Plasma cutting of CNC;

Step One: Cutting

Using a master CNC machine, cuts blanks according to size. Dimensions of parts can be viewed by downloading this file.

After cutting, the edges of the workpieces were sanded.

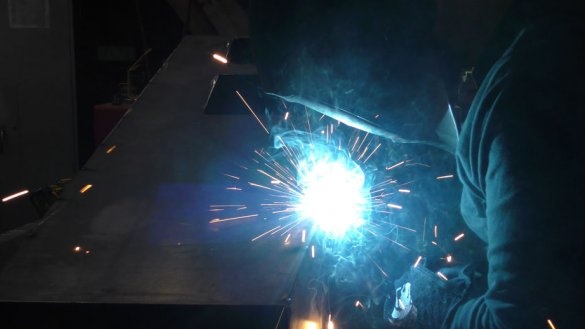

Step Two: Welding

Further, the master and his assistant weld the back and side walls.

Welds the front wall.

Step Three: Lower and Upper Ground

The fireplace has two compartments: the lower one for storing firewood, and the upper one for the hearth. The master measures the internal lower dimensions of the compartments. Cuts workpieces from metal. Welds.

Step Four: scald and strip

Then scalds the joints of the fireplace parts and cleans the seams.

Outdoor fireplace for the restaurant is ready.

The whole process of manufacturing the product can be seen on the video.