And again to all, good time. Today, the author of the TeraFox channel came across a gas cylinder with a volume of 8 liters, and he decided to make a beautiful wood-burning stove out of it do it yourself. Whole manufacturing process interesting homemade will be detailed in this article. And so that the master used for his furnace.

INSTRUMENTS:

pliers,

plasma cutter

electric drill,

vise

Angle grinder

magnetic squares,

file,

elbow

glass cutter

cold forging machine,

marker,

ruler

clamps

chisel,

semi-automatic welding,

cutting wheel for metal,

metal brush "piranha".

MATERIALS:

refractory glass, 4 mm thick,

asbestos sealant,

half an inch metal pipe

bolts and studs with nuts and washers,

gas cylinder

sheet metal 4 mm,

steel strip

steel bar

metal pipe, approximately diameter 50 mm

galvanized pipe

paper template

metal square,

profile pipe 15 mm by 15 mm.

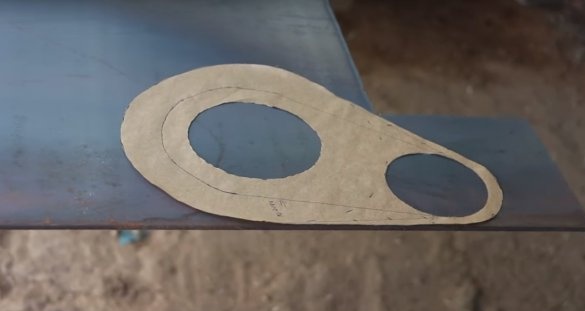

To begin with, the author will have to cut out from the sheet metal is not a simple part that will perform the role of a plate. According to a pre-made template, the author draws with a marker, the shape of the part on metal. Since the shape of the part is not simple, the master uses a plasma cutter.

A big minus of the field of such cutting is slag at the edges, it can be relatively easily removed with a chisel, which the master did.

To correct irregularities after cutting, the author tried with a nozzle on a drill, but the result, to put it mildly, was none.

And for this, the master took the file, according to the author working with a file, you get not the greatest pleasure, but the result is excellent.

Then he cut out a circle and drew another detail,

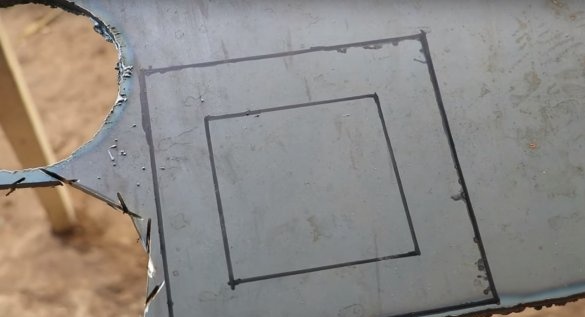

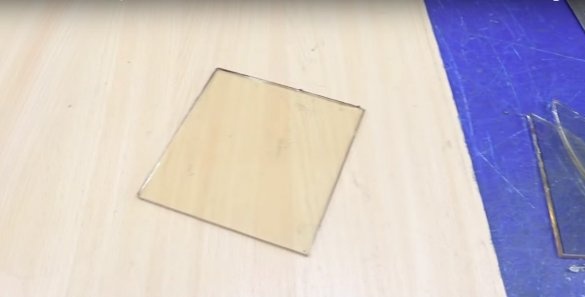

In the shape of a square with a square hole.

For an even and accurate cut of this detail, the author uses angle grinders with a cutting wheel.

Three main details are ready, now the author needs to build them into the cylinder. The metal strip will serve as the connection between the stove and the cylinder.

On the template, the author made slots for marking and marked with a marker the future location of the strip.

He shaped the strip, the author in place, welding and deforming the strip in the right direction.

After the strip was completely bent, he scalded it with a continuous seam on the outside.

Further, attaching the stove, the author made the marking on the cylinder.

After he removed the excess with the help of plasmoresis. The wall of the cylinder was not the same as in the large, but still there are 2 mm honest.

Then the master cut out another detail, it will be needed to plug the hole in the bottom of the plate.

After welded the item in its place.

Like this.

Fitting.

After that, the author welded restrictive plates under a metal circle, as shown in the photo.

Then he welded the stove to the cylinder.

Then he removed the old paint from the bottle.

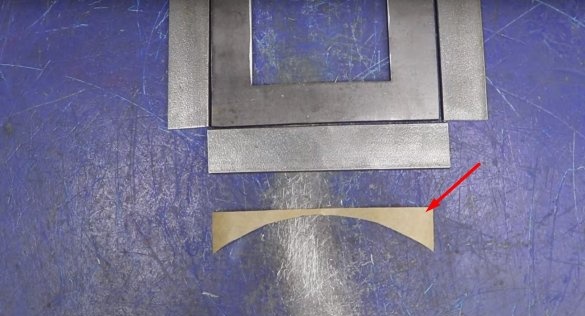

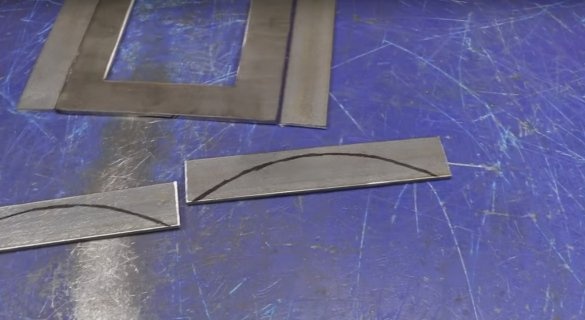

Four pieces of strip will be required to make the door frame.

The author will cut two of them in the shape of a balloon, cutting a small parabola.

After the author fixes all the details with magnetic squares and welds them without much effort.

Like this.

Then he marked out a place under the future door.

And cut to the markup.

From a profile pipe (cutting it in half), he made a stop for the door.

And also the author, will mark there an asbestos seal.

Fitting.

From the glass, the master will cut a square suitable for the size of the door.

The first thing to do is markup.

And then cut off with a glass cutter.

Are there any nuances when cutting refractory glass? The author says that he personally did not notice the difference in cutting between ordinary and refractory glass.

So it happened.

Then he made hinges for the door from the strip.

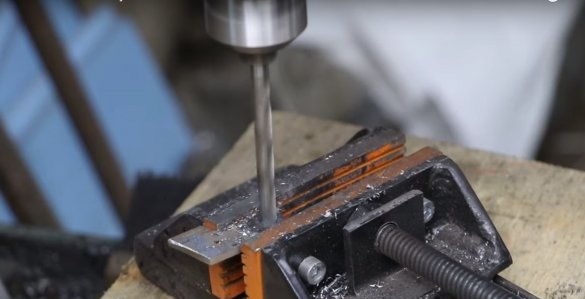

In each detail, the author made one hole.

Then bolted them together.

After fitting and fixing them by welding to the door and frame.

Further, the author, cut a small piece of pipe for the manufacture of valves.

I made the marking on the side because, according to the author: there were no other options here.

As a regulator of air flow, he cut out a 2 mm metal plate in the shape of a drop.

Welded a bolt and nut, as well as a screw under the handle.

Then I welded the door frame.

And the flap.

As unnecessary, the author removes the supporting heel of the cylinder.

And removes the remnants of paint.

He cleans the twisted square with a metal brush on the angle grinder.

This meter section, the author will cut into three equal pieces. And he will make of them legs for the furnace.

Previously twisting them a little.

To the base of the legs was not empty, the master added a small piece of pipe. And he welded the legs into place.

And it remains to weld the last element, this is a pipe.

After that, the author made a miniature poker with a small hairpin at the end, to hook the removable circle, set the door and painted the finished stove.

Such a wood burning stove turned out today by the author.

The door was sealed with an asbestos rope.

The master made glass fastenings from studs. Bending one of their edge.

And their second edge was fixed with nuts on the outside.

The first furnace test. Bookmark firewood and ignition.

Firewood flames up pretty quickly.

Blowing works fine.

To remove smoke, the author uses a pipe of 85 mm in diameter.

So it will be more comfortable to be at the stove.

The first test is cooking eggs.

For everything about everything, it took about ten minutes and the scrambled eggs are ready.

Now the task is more serious, on a closed burner 2 liters of water boiled for about fifteen minutes.

Well, the last test. In a cauldron for 4 liters. The author will cook the ear.

The author’s words: “I won’t say that the furnace quickly coped with its task, but nevertheless coped.”

This stove option is perfect for outdoor enthusiasts, for heating tents, etc. As you can see, the grass around it remained green and did not suffer from the temperature of the furnace. Fire safety, this is also important. Thanks to the author for a good homemade.

And that’s all for me. Thank you all and see you soon.