Essence homemade It was in the creation of the most compact and economical generator, which is easy to transport in the side trunk of a motorcycle and used in combination with solar panels in cloudy weather.

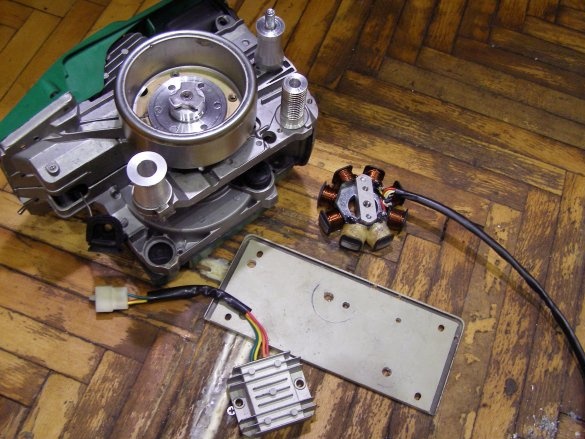

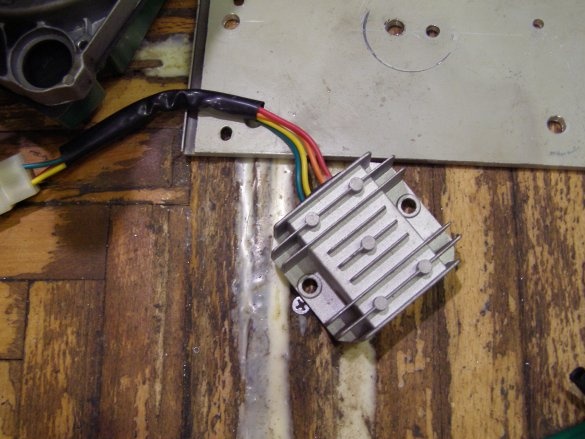

The basis was an incomplete chainsaw and generator from a Chinese 150 cc motor scooter with a 139JMB motor with an 8 pole stator, (preferably an 11 pole 3-phase motor from 152 or 157 motors, it is more powerful) and a standard relay regulator for it. All this was available.

Materials and tools.

Measuring electronic 30V and 10 amp head

Generator and relay regulator.

Duralumin plates.

Duralumin round billets (waste)

M8 studs, nuts, etc.

Turning, milling and drilling machines.

Development F12mm, drills, barbell, depth gauge.

Bulgarian

Step 1.

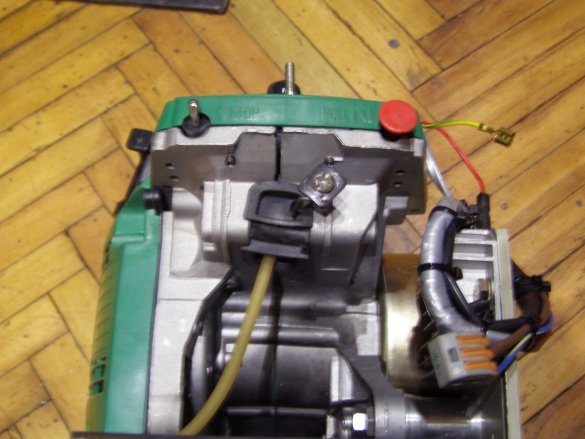

Removing everything unnecessary from the chainsaw body, only the gas pipeline with the filter from the tank and the cross nut from the centrifugal clutch are left.

Step 2. The landing flange has been removed from the generator rotor.

Step 3 A new flange was machined with milled grooves for the claw nut of the clutch nut, and an unfolded reamer after preliminary drilling with the bore diameter on the Ф12mm shaft. Also, the diameter of the neck of the flange entering the rotor bell was machined to the diameter of the hole in the stator to facilitate alignment and marking for mounting it on the side panel. (after installing the stator board on the panel, the neck diameter was cut through by 2 mm to create a gap). At the cross nut, the legs were shortened to the size of the neck of the flange. All this was assembled and mounted on a motor.

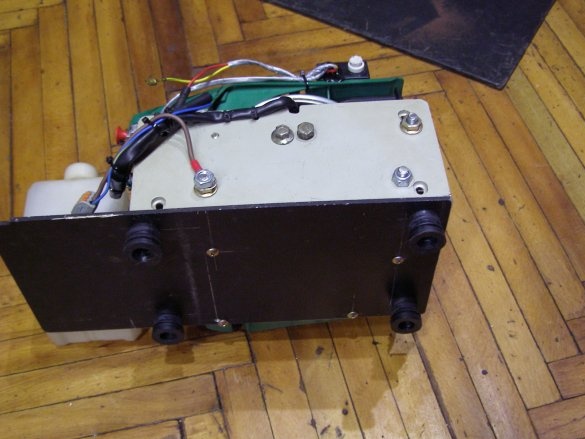

Step 3. Production of the racks of the panel and the panel itself as well as the intermediate cracker under the stator board. Marking and assembly of the board with the installation of a relay and all other components.

Racks Made from different residues and unnecessary parts, the only caveat is the height of all racks is different, it is measured and calculated for each separately, and the lower ends of the two racks in outer diameter should maximally correspond to the shock absorber sockets

Step4 Production of a base plate with damping legs from the shock absorbers of the chainsaw itself.

Step 5. Connecting the wiring and installing the measuring head, making the tank, and the gas screw.

The tank is made of packaging from electrolyte, it came complete with a battery. A native gas pipeline with a filter from a chainsaw is mounted in it, the hose really had to be increased, and due to this it became possible to connect any other tank of any capacity. Therefore, the tank has not yet been fixed to the support. I made the gas adjustment using a spring-loaded screw through a washer which I hooked with my own slightly bent draft.