The master has a double-sided grinding machine with a bath for water under the grindstone. This is not very convenient, because when using one stone, the other is turned away from you. If you need a second stone, you have to either bypass the machine, or raise and deploy. The master decided to simplify the use of the tool and make a rotary platform, on which the machine itself is already fixed.

Tools and materials:

-Fasteners;

-Plywood;

- dowels;

-A circular saw;

-Drill;

-Drilling machine;

-Grinder;

-Screwdriver;

-Drill;

-Gon;

-Lathe;

-Pencil;

-Kern;

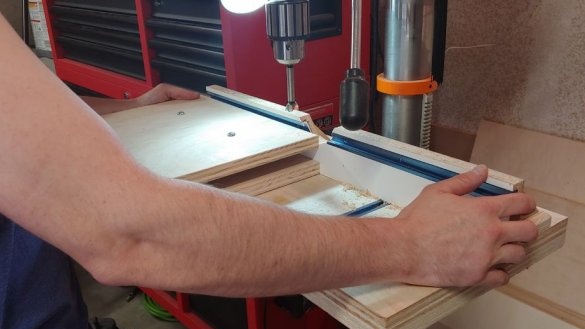

Step One: Sawing

The platform consists of two parts made of plywood and a rotary mechanism installed between them. Two squares need to be cut out of plywood, with the calculation of the installation at the corners of the latch.

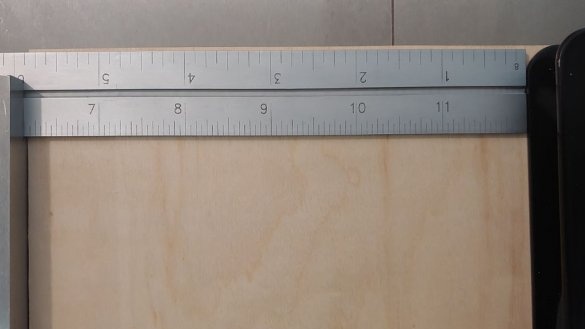

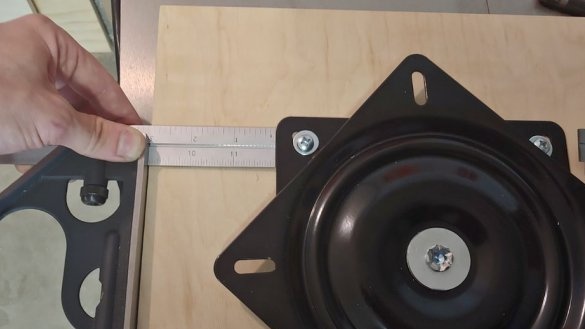

Step Two: Markup

Next, you need to install the rotary mechanism in the center of the workpiece. The wizard marks the installation location and makes markings for fasteners.

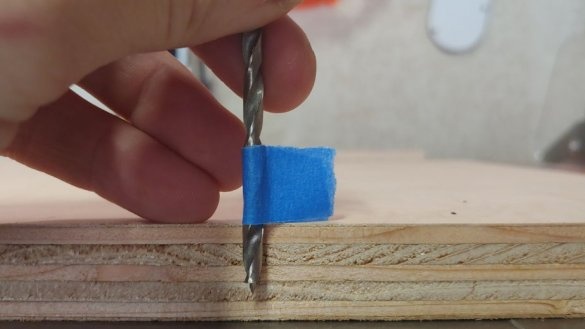

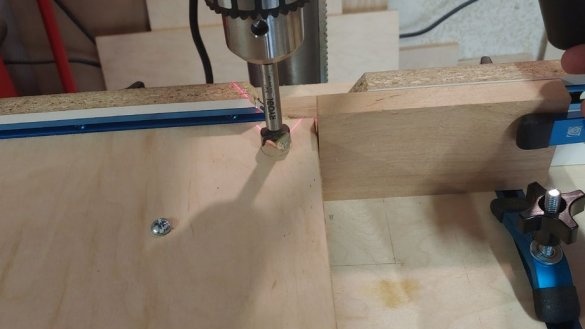

Step Three: Installing the Mechanism

Drills a blind hole and screw the rotary mechanism to one of the workpieces.

Step Four: Installing the Top of the Base

Now you need to transfer the marking to the second workpiece and drill holes. The upper platform is fastened with bolts and nuts.

Step Five: Grinding

Grinds the product, cuts off sharp edges.

Step Six: Lock

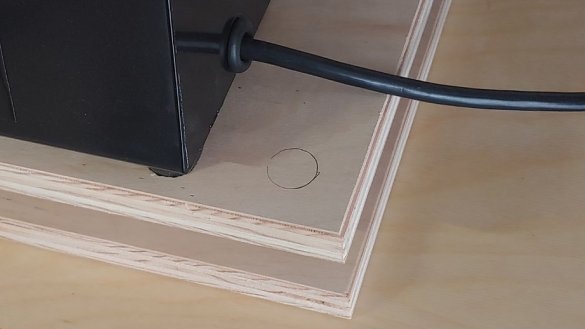

In principle, everything is ready, but the master advises making another latch. The clamp will prevent the machine from moving during operation.

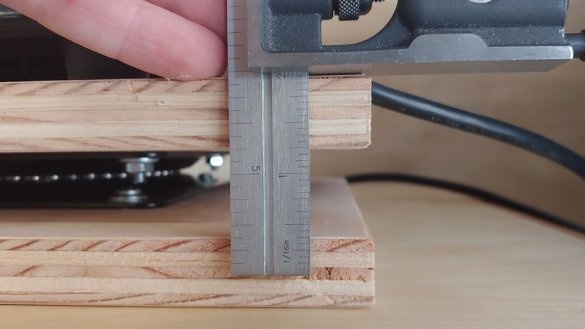

Measures the distance from the middle of the bottom plywood blank to the top of the top. Adds another five centimeters. Cut the dowel according to calculations.

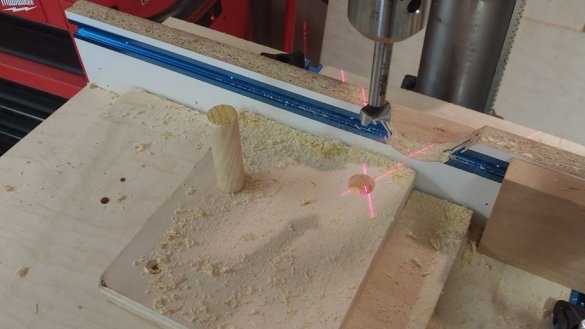

At the corners of the platform, makes markings on the diameter of the dowel. Drills a hole in the upper platform through, in the bottom deaf. The same blind hole makes diagonally in the opposite corner of the lower platform.

The edge of the dowel slightly grinds with sandpaper.

Now the dowel enters effortlessly into the hole.

Seventh step: locking knob

For ease of installation of the latch master makes a handle. Drills a blind hole in plywood along the diameter of the retainer. Slices a workpiece with a hole.Applies glue to the hole and sticks the dowel.

Installs the latch in the lathe and grinds the handle.

Apply wax to the fixative.

Now everything is ready. Great idea and you can use it in other projects.