It would seem that there are contradictions in the words “circular machine” and “mobile”, but the master’s goal was precisely to combine both of these concepts in one device.

Why does the master need this? According to him, when working at the facility, it is difficult to deliver a circular machine there, and then he got the idea to make such a machine so that it could be easily assembled and disassembled. Those. it is a working tool, the main thing in which is mobility and usability, rather than appearance.

Tools and materials:

-Plywood;

-Plastic boxes -3 pcs;

-Boards;

- Cart wheels -4 pcs;

-Fasteners;

-Epoxy adhesive;

- Latches;

-A screwdriver;

-Sawing tool;

Step One: Foundation

The base is made of plywood and boards. The bottom drawer is attached to the base using latches. Four wheels are fixed at the bottom of the base for easy movement of the machine. Before working under the base, the master fastens two bars with anti-slip material.

Step two: securing the drawers

As already mentioned, the bottom drawer is fixed with latches. For this, holes were drilled in it.

To fix subsequent boxes, the master attaches a block in the corner of each box. A through hole is drilled in the bar and a nut is installed from below. The upper box is installed on the bottom and fixed through the block, with a bolt.

Step Three: Tool Storage

Boxes also have the function of storing tools. The master carves the walls in the two lower drawers and installs sliding doors.

Step Four: Top Drawer

The top drawer mount is similar to the middle one. There are no doors in the box, a saw will be installed in it.

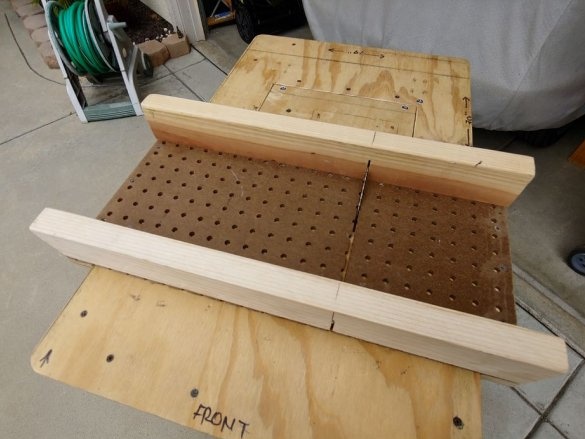

Step Five: Desktop

The desktop is made of plywood. Attaches to the top drawer the same way. The circular saw is mounted on a separate panel, which is mounted in the middle of the desktop. The master did this so that, if necessary, the saw could be removed and the panel replaced in its place. Then you can use the machine for other purposes, such as an extension table for a large circular saw in the workshop of the master.

Step six: work with the saw

The master fixed the power button on the circular saw with electrical tape.Now, to turn on, just plug the plug into a power outlet.

Also, for ease of use, guides and a pusher were made.

Such homemade It turned out, it would seem, from objects that are not quite suitable for these purposes.

According to the master, this is not a complete replacement for a circular saw, but for certain types of work, a normal working tool. Like any tool, this machine has a number of advantages and disadvantages.

Pros:

-Good circular saw, if it is not possible to have a full-fledged machine

-Easy to mount and dismantle

-Boxes are used for tool storage

-Wheels make it easy to move the machine.

Minuses:

- The main disadvantage of the machine is its small size, which does not allow for a complete sawing of the material.