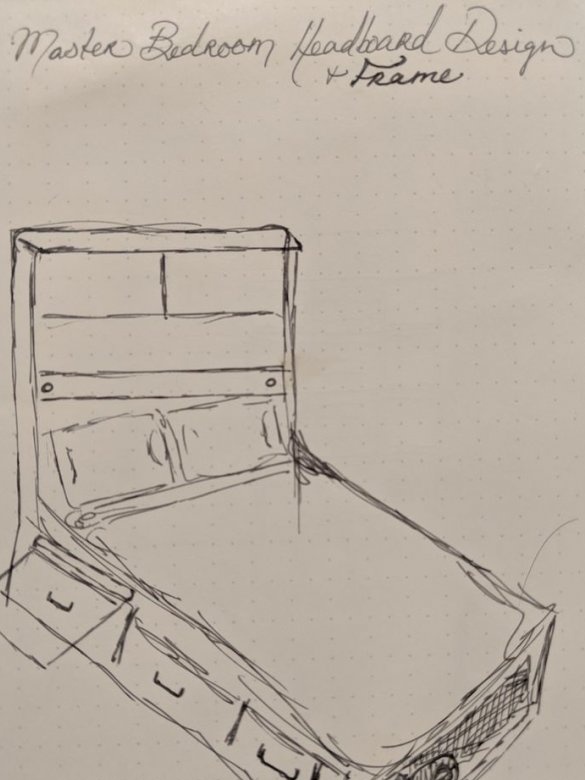

After buying a house from the master, the question arose of purchasing a bed in the bedroom. The requirements for the bed were as follows:

-The bed should be high

- Beds should have drawers

-Must be a bookshelf

Sleeping place for home animals

-Good mattress

All the beds examined in the store did not fit either in the parameters or in the budget, and then the master decided to make a bed and a mattress on his own.

Tools and materials:

-Plywood;

-Board;

- corners;

-Fasteners;

-A screwdriver;

- Joiner's glue;

-A circular saw;

-Material for the mattress (2 foam, latex and cover);

-Gon;

-Level;

- Electric jigsaw;

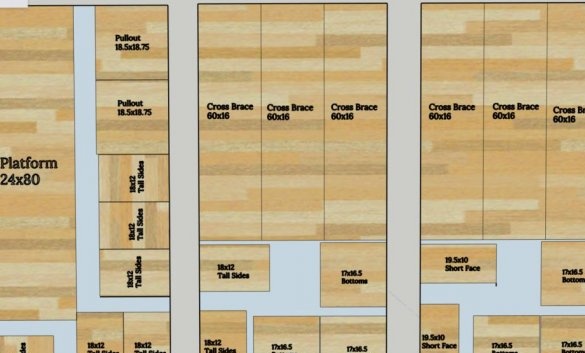

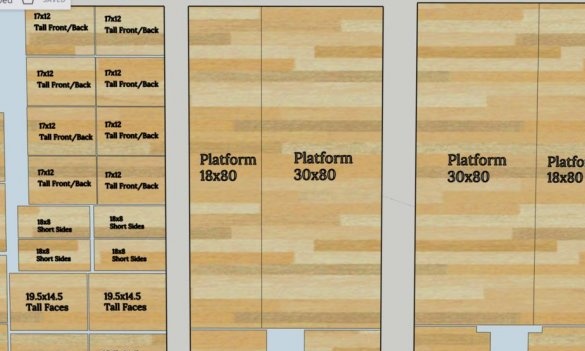

Step One: Cutting Material

According to the drawings, the master performs the sawing of the material.

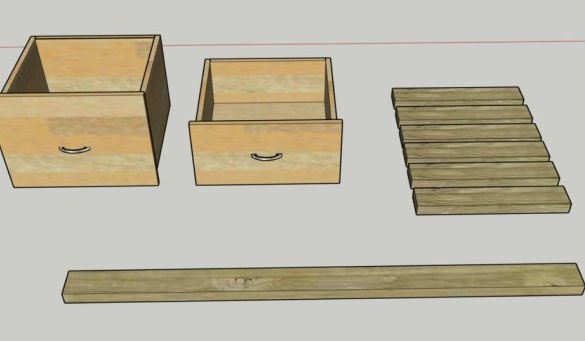

Step two: assembly of boxes

Collects boxes fixing parts with glue and screws. In total, you need to make 6 boxes, three on each side.

Step Three: Frame Assembly

The bed is assembled at the installation site. Joins the two bottom sheets with metal plates. Fastens transverse parts.

Step Four: Headboard Assembly

Gathers the head of the bed. The headboard has long protruding boards at the bottom, for the possibility of firmly fixing it to the bed.

Step Five: Installing Boxes

Installs boxes in niches, fastens front panels.

He paints the bed, fastens handles on the drawers.

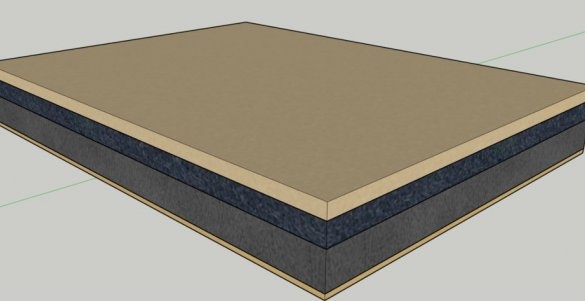

Step six: assembling the mattress

The master collected the mattress from previously ordered materials. The mattress consists of three layers of foam and latex. The first is the base 12-cm layer of foam, then the gel layer is 7.5 cm and, on top, 5 cm of the latex base. A cover is put on top of the mattress.

According to the master, the mattress is not inferior to store samples, but at a price it costs 60% cheaper.

The whole process of making a bed and mattress can be seen in the video.