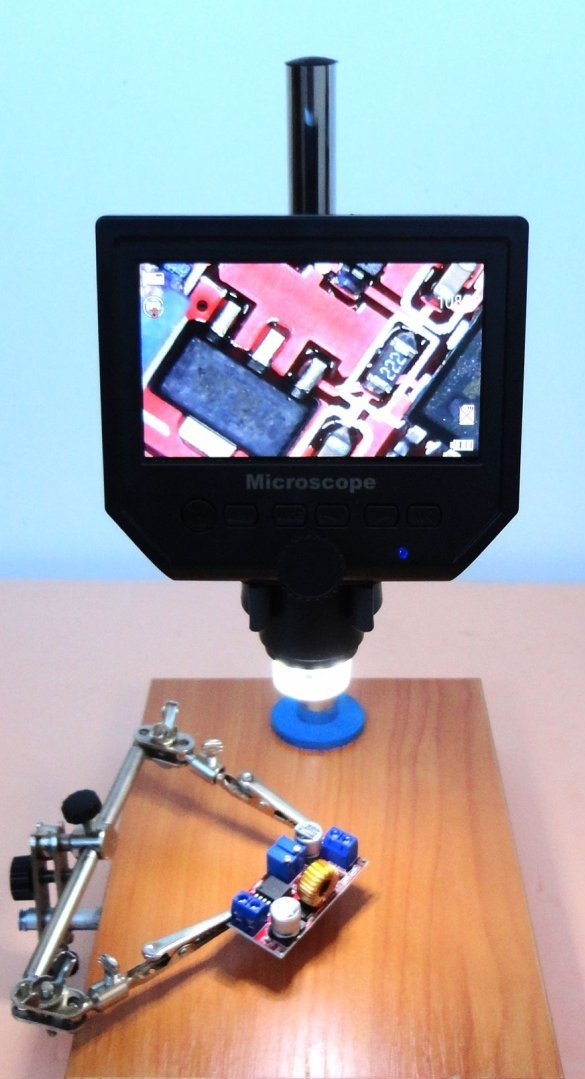

The need for such a design arose when I tried to use my native Chinese kit. The native stand is too small and light. Even with a light touch of the microscope, continuous shaking of the image begins. I do not see the need to spend an extra 1000r (which is half the cost of a microscope) on a more expensive metal one, because it is not known how much this “miracle” of Chinese technology will survive. But while he pleases me.

The photo shows the real quality of the microscope on a fragment of the board of the Chinese module, with its average magnification.

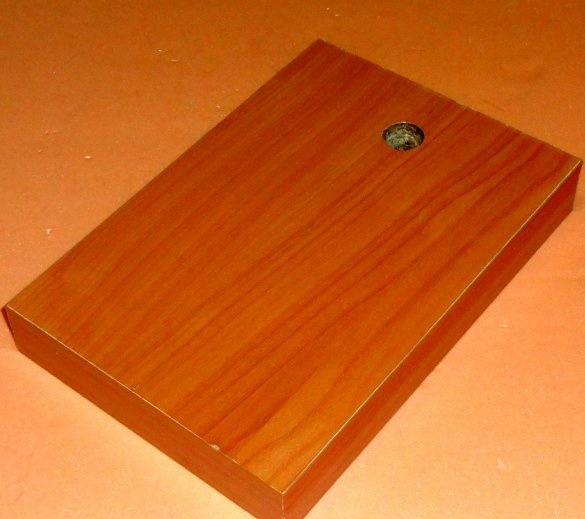

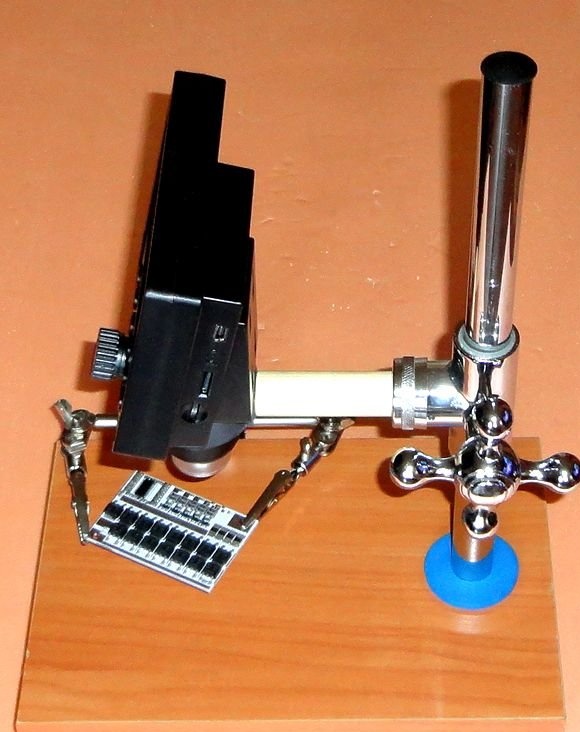

Native delivery kit (that's what it was).

The idea was to use the materials, parts, and tools I had on hand. Without running around shopping and spending money.

In this design was used:

- details of an old broken shower holder

- two panels of chipboard with dimensions of 150x220x16mm

- screw with nut M4

- screws with a diameter of 3.5mm, 4mm

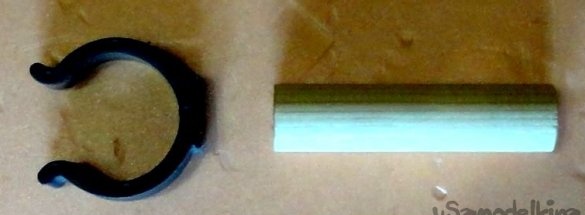

- aluminum tube with a diameter of 8 mm long 25 mm

- round wooden profile with a diameter of 18 mm long 75 mm

- a plastic fragment of the brush holder from the vacuum cleaner

- universal epoxy adhesive

- colorless varnish ХВ-784

- edge tape

Of the tools used:

- cutting machine

- drill stand

- jigsaw

- screwdriver

- files

- clamps

- iron

Unfortunately, I didn’t find a piece of a thick countertop (and the base of such devices should be quite weighty), so I used two pieces of chipboard with dimensions of 150x220x16mm as the base. Which were fastened with screws, after which an 18mm through hole was drilled in them. An edge tape was glued onto the slices using an iron.

A fragment of a tube from an old broken shower holder with a diameter of 17.5 mm and a length of 300 mm was used as a tripod. A fragment with no oxides was selected, chromium plating did not suffer.

The tripod is fixed to the base with a screw with an M4 nut and epoxy glue, which ensured reliable mounting without any possible backlash (i.e. tightly).

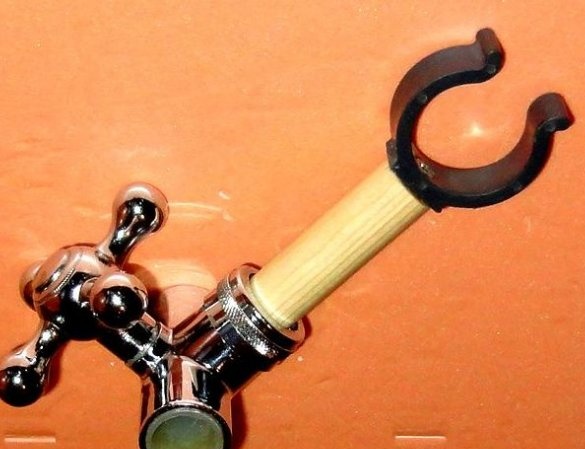

The microscope holder is made of a shower holder, a round wooden profile with a diameter of 18 mm and a length of 75 mm and a plastic fragment of a brush holder from a vacuum cleaner.The wooden profile is coated with colorless varnish and tightly glued to the holder using epoxy glue. A fragment of the brush holder from the vacuum cleaner is screwed to it with a sufficiently long screw (see photo).

I was very pleased with the plastic insert in the shower holder. Thanks to her, moving around the tripod is very smooth and chrome is not scratched.

Rubber feet are glued to the bottom of the base.

The tripod is wearing a blue rubber washer. A black plastic plug is inserted on top of the tripod. An aluminum tube with a diameter of 8 mm and a length of 25 mm is fixed on the side of the base with a screw with a diameter of 4 mm.

The aluminum tube serves to enable, if necessary, install the holder from the industrial version of the "third hand", which turned out to be very convenient. When unnecessary, it is instantly removed and does not interfere. It is very convenient when you work with tweezers and a soldering iron at the same time or with two multimeter probes at once.

The height of the tripod is made with a margin (relative to the Chinese versions), in relation to the possible focal lengths of the microscope, which makes it possible to conveniently examine the details on larger objects.

The design is very stable. The base of the microscope with a diameter of 34 mm is fixed tight enough and does not scratch. The possibility of free rotation of the microscope retainer around the tripod was also very useful.

The microscope works according to the principle - the farther from the object, the lower the magnification factor. Therefore, it turned out to be more convenient to work with a soldering iron at medium and small magnification, so as not to damage the microscope itself. At high magnification, it is convenient to search for poorly visible damage and microcracks, etc.

Due to the decent dimensions of the base and the height of the tripod, it is possible in the future to easily install additional devices if they are needed during operation.

If you need additional information, write to the post office, I will try to be sure to answer.

Feedback, suggestions and comments are very welcome.

June 2019