Greetings to all fans of cycling. Such a transport is indispensable for the city, many go to work by bicycle, no need to spend money on transport, and it’s good for health. But what if you need to travel far or very often? There isn’t enough muscular strength for everything, then we begin to think about whether to equip our own. In this homemade we will look at how this can be done simply and not expensively. Of course, bike it becomes a bit heavy, and the batteries occupy the trunk, but for some time you can ride without making any effort. When the battery is discharged, the bicycle can continue to move in the classical way, the design of the bicycle does not change. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- ;

- engine speed controller;

- batteries;

- electronic throttle handle;

- driven asterisk from the bicycle;

- chain;

- corners;

- iron plates;

- sheet metal;

- door hinge;

- fiberboard;

- experimental bike;

- paint.

Tool List:

- grinder;

- welding machine;

- a tool for soldering copper;

- spanners.

Homemade manufacturing process:

Step one. Installing a driven sprocket

To begin with, we disassemble the bicycle, remove the rear wheel. On the wheel we need to install an additional sprocket for the engine. The author used a small asterisk with a ratchet mechanism so that the engine shaft would not rotate when coasting or on pedals. The central part of the sprocket must be attached to the wheel hub, this can be done by welding, but there are big risks to damage the hub. The author decided to solder the sprocket with brazing alloy, copper was used for this. This fastening is quite reliable, if you do not carry large loads and do not accelerate too sharply.

Step Two Engine installation

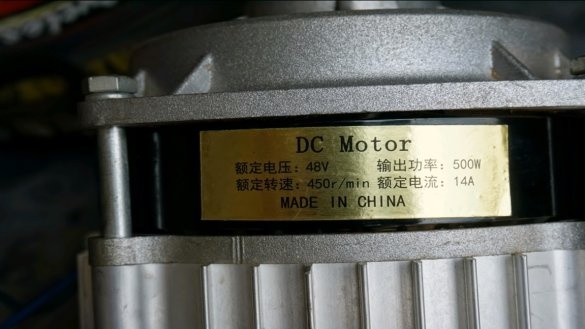

We proceed with the installation, the author has a 500-watt unit, which is powered by a voltage of 48V. An interesting fact is that the author feeds the motor with two series-connected 12V batteries each.

For the engine, we make two fasteners from the corner, fasten them to the motor, and then weld to the rear fork of the bicycle, watching the sprockets. At the end, it remains to install the circuit.

Step Three Battery pack

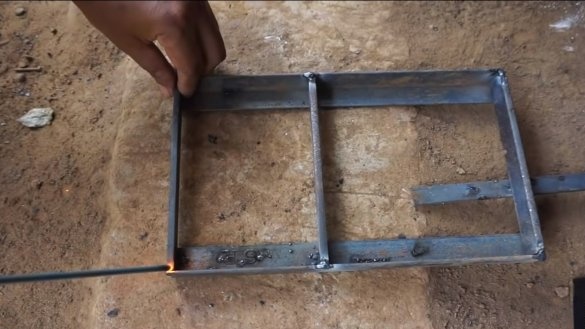

We assemble the battery pack, the author installs two batteries for 12V of 26Ah each. First, we weld the frame from corners and iron plates, the frame is welded to the trunk.Be sure to make a sheet metal cover that will be locked, this will protect the batteries from theft. In addition, a speed controller is installed in the battery pack. We connect the batteries in series and check the performance of the design.

Step Four Completion and test

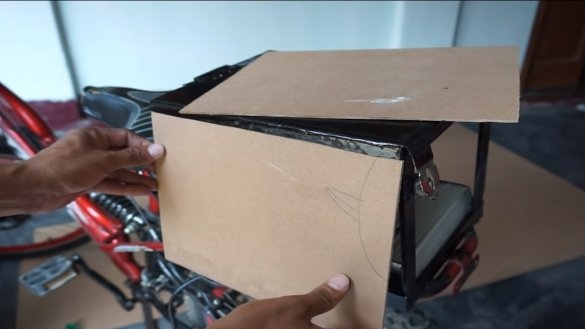

At the end, we sheathe the fiberboard battery pack, and better with plywood and paint. Do not forget to weld the hinges to install the lock. We install an electronic throttle handle on the steering wheel, carefully conduct the wiring through the frame and fix everything with plastic ties or electrical tape.

That's all, the bike is ready, the author pulls away pretty quickly. The engine turned out to be quite powerful with good torque. What is the mileage and maximum speed of homemade remains unknown. On this project is over, I hope you liked the homemade. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!