I welcome all fans to craft, if you have an old faulty compressor for 12V or the like, do not rush to throw it away, you can collect a wonderful one from it homemade! Today we will consider how to build a powerful compressor based on a grinder. Such a compressor is so productive that it easily inflates a disassembled tubeless scooter wheel. The author also connects a spray gun directly to the homemade product and paints it without difficulty. Of course, if the pump assembly of the compressor is weak, it may not withstand torque, speed and too high pressure, so it is best to lubricate everything and install an emergency valve. One way or another, if the project interests you, I suggest studying it in more detail!

Materials and tools used by the author:

Material List:

- An old compressor for a car;

- a sheet of iron for the base;

- iron plates;

- a piece of iron pipe;

- round timber;

- bearing;

- long nut (on the thread of the grinder shaft);

- screws and other little things.

Tool List:

- lathe;

- drill or drilling machine;

- tap for threading;

- welding machine;

- ;

- screwdrivers;

- tape measure, marker.

Compressor manufacturing process:

Step one. We disassemble the compressor

To begin with, we will analyze our old faulty compressor, usually this weak brush motor breaks in them. It is also recommended to inspect and, if necessary, lubricate the piston assembly. We remove the case with permanent magnets, we do not need it. You also need to remove the anchor from the axis of the engine.

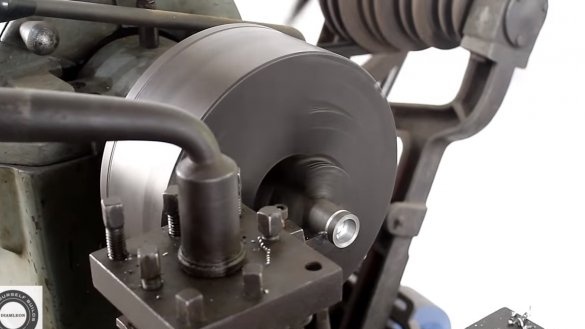

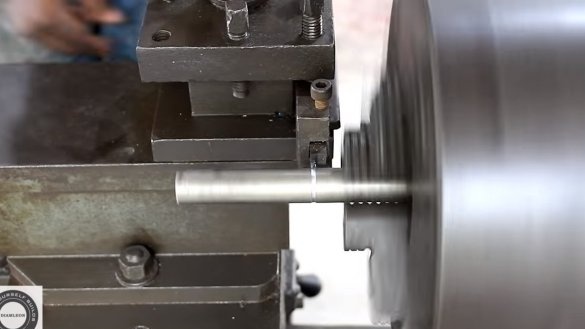

Step Two Making a new case

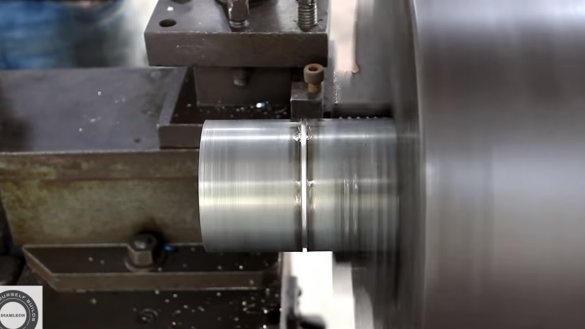

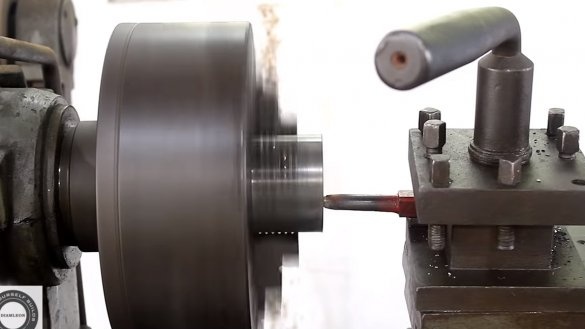

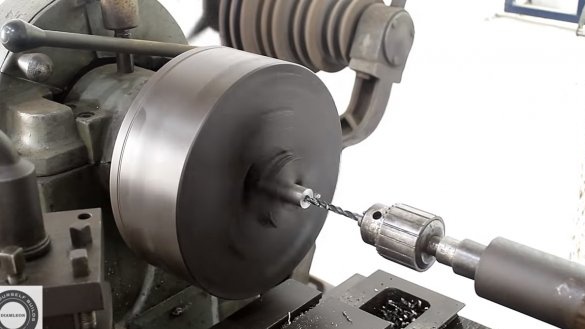

For the compressor, we will manufacture a new housing from a piece of pipe of the same diameter as the diameter of the former engine housing. For the body, you will need to plug the back with a sheet of iron and drill a hole under the axis in the center. All such work must be carried out on a lathe.

There should also be a bearing in the housing, a clip must be made under it. Usually the clips are made of a pipe, but if there is no such pipe, you can turn the clip from a round on a lathe, as the author did.We weld the clip to the case, and now it is ready. The author also made new screws for attaching the housing to the compressor.

Step Three Installation of the compressor on the base

As a basis, we are looking for a sheet of iron of suitable thickness. We attach corners to the compressor housing as fasteners and drill holes in them. At the core, the author also drilled holes and cut a thread. Well, now the compressor can be securely screwed to the base.

Step Four Connection unit

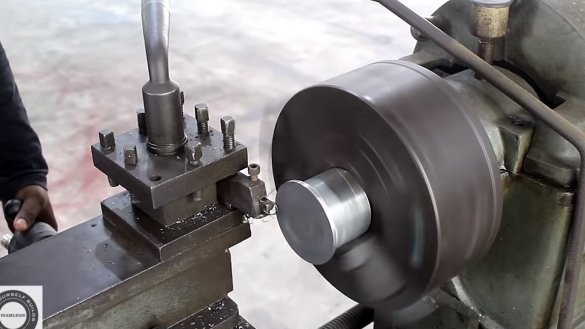

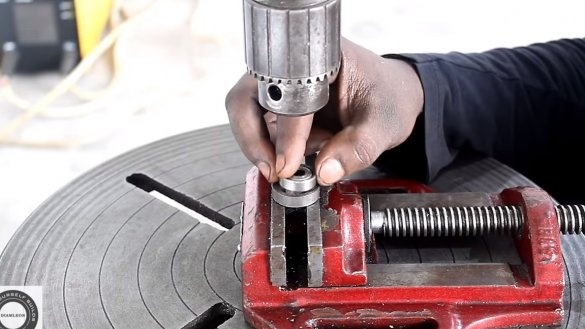

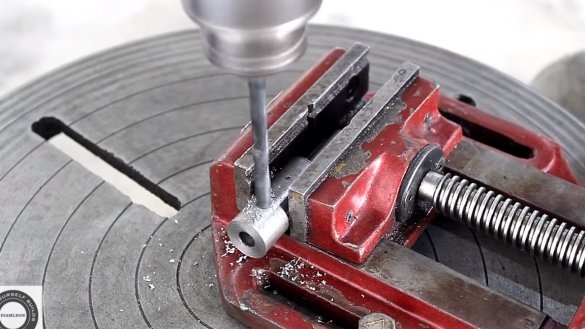

Next, we have to make a connecting node, which will dock the shafts of the grinder and compressor. We take a round and grind one part so that the nut fits tightly on it, with which we will connect to the shaft of the grinder.

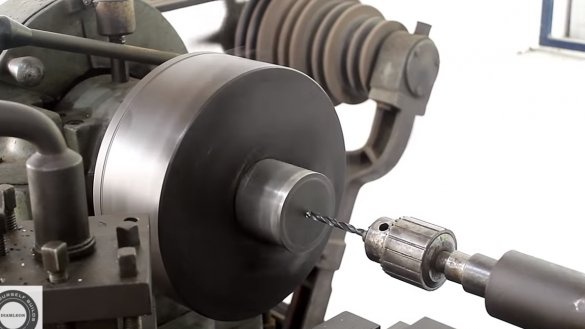

On the other side of the round timber we drill a hole along the diameter of the compressor axis, and we also drill holes perpendicularly with a drill and cut the thread for the fixing screws. It remains only to weld a nut, and now the adapter is ready!

Step Five Bulgarian fasteners

We manufacture fasteners for the grinder, but first we connect the working shafts. The fastener is a thick iron plate that is welded to the base. We fasten the grinder with a bolt that is wrapped in a hole for mounting the front handle. That's all, now it remains to paint the homemade product so that it does not rust!

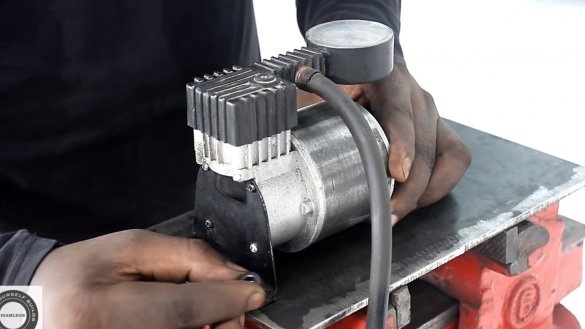

Step Six Test

We turn on the compressor and try it in practice, as an experiment, the author pumps up a disassembled tubeless scooter wheel, the air volume for this is large. Homemade easily copes with the task.

Also, the author blows off the chips from the compressor, and in the end, he connected the paint gun to the compressor and tested it in practice. The homemade product turned out to be useful, the grinder can be easily removed and put at any time on the machine.

On this project is over, I hope you liked the homemade. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!