I welcome fans to craft, today we will consider how to make a convenient and powerful vice based on a hydraulic jack. In assembly homemade not complicated, almost everything is made of metal. The vise easily compresses a rather thick iron pipe, the lips open themselves when the pressure in the jack is relieved by a tap, furniture springs are responsible for the extension of the lips of the vise. If you need such a vice and you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- channel;

- thick sheet metal;

- corner;

- furniture gas springs;

- bolts and nuts;

- hydraulic jack;

- paint for metal.

Tool List:

- ;

- plasma cutter (preferably);

- drilling machine;

- tape measure, marker;

- grinder;

- ;

- taps for threading.

Vise manufacturing process:

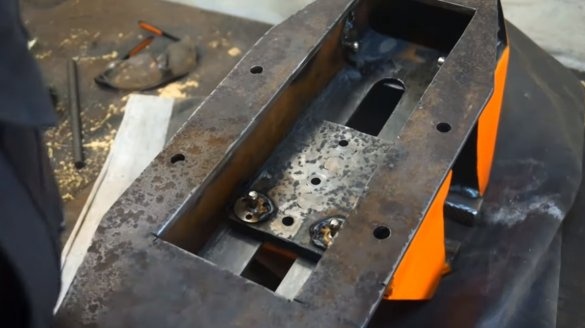

Step one. The foundation

We start with the basics of a vise, for these purposes we need a strong channel. Cut off the desired piece and clean it from rust. Next, we will need iron plates, they will need to be welded on the sides of the channel, these plates will act as guides for the movable lip.

In the center of the base you need to make a cut, it will also serve as a guide for the lips, and springs will also be installed on the back side.

Step Two Lips and pads

We collect lips for a vice, for this you need a thick sheet of iron. The fixed lip will be at the end of the base, we make all welds as reliable as possible.

Under the movable lip we make a platform of an iron plate and corners, which will move along the base.

We also make lip linings, it would be nice to use carbon steel, steel bars or thick plates are suitable. The author makes a grinder on the overlays so that the overlays reliably hold the product. Well, then we weld the linings to the lips, and even better, screw them on.

Step Three Springs

For a vise, springs are needed that will part the lips.The author used gas furniture springs, but ordinary iron springs can also be adapted.

Step Four Emphasis for a jack

We make an emphasis for the jack, this node should be as strong as possible, since the loads here will be considerable. We weld the stop from a piece of a channel, as well as thick iron plates. The author decided to fix the stop with screws, for this we drill in the base of the hole and cut the thread.

Step Five Base and assembly

We cut out the base for a vice from thick sheet iron and weld it. Using the base of the vise, you can fasten the table with bolts and nuts.

When everything is ready, carefully clean the welds and paint the vice with metal paint. That's all, the homemade product is ready, the vice can be collected. We put in place the lip, as well as the springs, in the end it remains only to put the hydraulic jack.

The homemade product works perfectly and quite quickly, the round pipe clamps quite reliably. The author also demonstrated the work of a vice, squeezing the end of a round pipe made of fairly thick metal.

This is the end of the project, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!