I welcome all fans to craft, today we will consider how to make a useful nozzle for a grinder. This homemade for men with me, but seriously, be careful! We will talk about such a homemade product as a blower, with such a machine you can blow off leaves, construction debris and perform various other work. The shaft of the grinder develops high revolutions, so the manufacture of such a nozzle is quite justified. The impeller can be considered the main difficulty in making a homemade product, it must be well balanced, otherwise strong vibrations are inevitable, which will most likely quickly wear out the bearing of the Bulgarian reducer. The author needed a lathe and some metal to make a homemade product. One way or another, if the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- sheet metal;

- a piece of iron pipe (for blades);

- bolts;

- ;

- paint for metal;

- a piece of pipe for the outgoing part.

Tool List:

- lathe;

- grinder;

- welding machine;

- Miter saw;

- drill with crowns.

Homemade manufacturing process:

Step one. Body manufacture

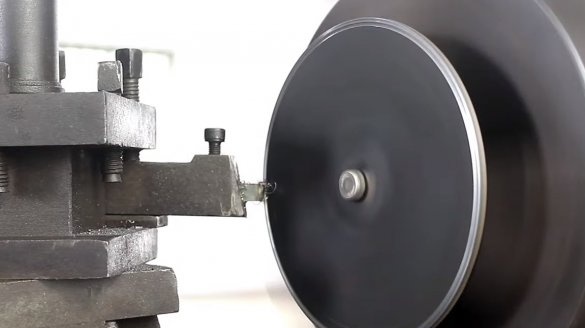

To begin with, we need a carved circle from an iron plate, this will be part of the body, a grinder will be attached to the same part. It is better to use thicker sheet metal so that everything is fixed securely. In the center of the circle, you need to drill a hole with a crown, the Bulgarian shaft and part of the body will enter here. To drill a hole clearly in the center, the author used a lathe.

Next, we need to cut a piece of pipe and weld in front of the hole to the sheet, this will be an emphasis for the grinder.

We will fix the grinder using a removable handle and a bolt on the other side. Mounting brackets are made of thick iron plates. We drill holes for the bolts and weld the plates in the right places. To begin with, the plates can be screwed to the grinder and only then grab them together with the grinder to the base.

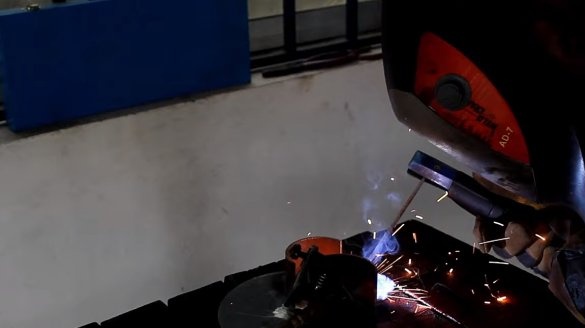

At the end of the step, you need a thinner sheet metal, scald it with a base in a circle, as a result, the main part of the body will be ready. We clean the welds with a thick grinding disc so that everything looks neat.

Step Two Impeller

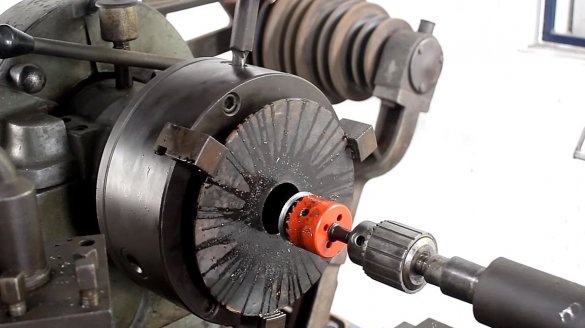

We turn to the most responsible occupation, we need to make an impeller. Here we again need a circle of sheet metal, it is better not to make a circle larger in diameter than the cutting discs that go to the selected grinder. In the center of the circle, we drill a hole for the engine shaft, and we also make blades.

To make the blades, you will need an iron pipe of suitable diameter, and it is better that the iron be thinner, since we do not need excess weight. We cut the pipes as in the author and then weld to the base. Everything should be collected clearly symmetrically, otherwise there will be strong beats. During the welding process, make sure that the welds are approximately the same size everywhere, so that there is no strong spread in weight. Of course, in any case, vibrations will be inevitable.

Step Three Inlet

Cut out another sheet metal circle and weld to the body. In the center of the circle, a hole must first be cut with a crown. Through this hole, air will be sucked into the blower, the machine we have is a centrifugal type, like most vacuum cleaners.

Step Four Outlet pipe

The homemade product is almost ready, it remains to install an outlet pipe through which air will blow. We select a piece of pipe of the desired diameter and cut it at an angle. On the side of the body we drill a hole and weld the pipe.

Step Five Completion and testing

Having cleaned the welds, the homemade product can be painted to protect it from rust, and the car will look much more interesting. Now the nozzle can be installed on the grinder, we fasten the grinder with a bolt, as well as with the front handle. As a result, we will be able to securely hold the car in our hand thanks to two handles.

In the end, it remains to screw the impeller to the shaft, here everything is already done with standard nuts.

The homemade product is ready, it is highly desirable that the grinder has a speed control, since the impeller is quite heavy, a sharp start will harm the engine and gearbox. In addition, the result of starting such a homemade product is always unpredictable. But our author starts the car quite boldly, whether the blower works at full speed or not, remains a mystery. In general, the blower generates a pretty good airflow.

One way or another, be extremely careful when introducing such homemade products into life and testing. This is the end of the project, I hope you liked the idea, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!