In this article, the Master will tell us how he solved the problem of transporting bulky goods. When, he had a need for building materials, it turned out that his delivery was not cheap. Then the master decided to make device on his autoto get by on your own. Of course, all cars are different, and not everyone will have such a trunk, but the main thing is to show the direction.

Tools and materials:

-Wood;

-Bandsaw machine;

-A circular saw;

-Paint;

-Painting brush;

-Roulette;

-Marker;

-Fasteners;

-A screwdriver;

-Plywood;

- Joiner's glue;

-Hooks metal;

- staples;

Step One: Material Procurement

For the trunk you need the following materials.

-Bar 1410 mm - 4 pcs;

- Bar 807 mm - 4 pcs;

Plywood covers of various shapes - 8 pcs.

Step Two: Fit Racks

At the corners of the side of the body of the auto master, there is a profile pipe. It is necessary to trim the edges of the short bars so that they go into the holes of the pipe.

Step Three: Lining

The purpose of installing the linings is to increase the rigidity of the structure and to eliminate the movement of the struts during braking or acceleration. The master installs the racks in the desired position, and on two screws, the holes will serve as a guide in the future, bolts the lining to the racks. Then the racks are removed and the pads are dismantled. Glue is applied to the racks and the pads are screwed completely.

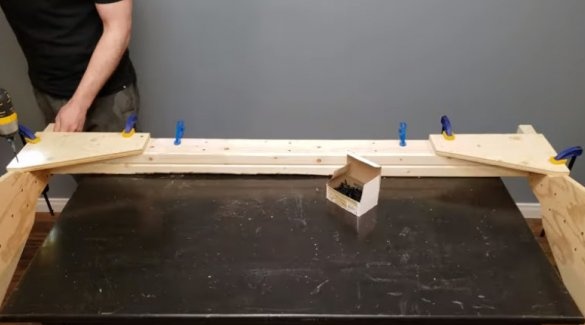

Step Four: Cross Beams

Cross beams are made of long beams glued and fixed with screws.

Beams are mounted between the two front and two rear pillars.

For reinforcement, in the corners, corners are made of plywood.

Step Five: Painting

Finished elements of the trunk master paints the body color, black.

Step Six: Trunk Installation

Now you need to fix the trunk on the back. The master installs the racks, and secures them with metal hooks to the body.

For strength and facilitate the process of loading and unloading material secures two beams along the side.

Everything is ready, the trunk is installed and tested in practice.

The whole process of manufacturing such a trunk can be seen in the video.