Surely many of you have heard about the thicknesser, and some have worked with it.

In this article, the author of the YouTube channel "StoDel_56" will tell you about one small secret, which allows you to perfectly accurately repeat the thickness of the workpiece, copying it from the finished one.

Materials

- Wooden planks.

Instruments, used by the author.

- Reysmus.

Manufacturing process.

The master himself learned about this function of the machine a few months ago. The most interesting thing is that not a word was said about it in the instructions and descriptions of the thicknesser.

So, he prepared the details for the manufacture of skirting boards. But its quantity was simply not enough, and now we have to do a few more blanks. They must be exactly the same size.

The master cut two bars one meter long.

At the moment, the height at the thicknesser has remained the same, so that one size at the slats can be processed immediately.

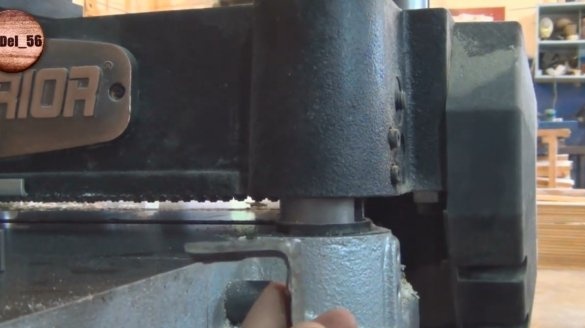

For this, the developers of the machine specially processed the bottom surface near each of the columns. It is clearly visible that it is polished.

The upper surface is processed by milling, but the same is perfectly smooth.

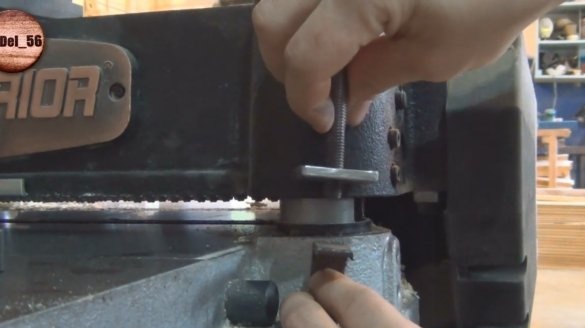

Now the wizard simply inserts the machined part between these planes. She comes in very tight.

In order to process the new rails in the second size, you need to release the rack locks and reduce the height. The part is simply squeezed between the planes. Then clamp the clamps, and process the trims.

Putting the original and the copy together, you can clearly see that their sizes are absolutely identical.

The author still uses knives that were installed at the factory, they are not resharpened and not removed. To replace the knives, a special tool comes with the machine deviceby which the knives are set in the correct position.

If the author had not discovered such a feature of the machine, he would have made the simplest device on his own. To do this, a pair of corners, and a screw with a lock nut, are suitable. Such a device will also have the ability to calibrate. Details simply need to be fixed near the column.

Thanks to the author for a simple but useful secret!

All good mood, good luck, and interesting ideas!

Author video can be found here.