Hello to all lovers, today we will consider homemade, which can significantly expand the functionality of the grinder. It will be a broach that will allow the grinder to cut exactly in a straight line. In addition, if you upgrade the holder, you can easily fix the plasma cutter on the carriage and cut the thick metal with a machine. The carriage can be clamped, thereby completely eliminating the backlash, which is very important. Homemade made under the profile pipe 40X40. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- square pipes of small diameter;

- profile pipe 40X40 for the guide;

- 8 bearings (go as rollers);

- bolts and nuts;

- a piece of a round pipe;

- 2 bearings for a hinge with a holder;

- a few bars;

- iron plates.

Material List:

- drilling machine;

- grinder;

- measuring angle;

- spanners;

- tape cutting machine or miter saw (optional);

- welding machine;

- paint for metal.

Homemade manufacturing process:

Step one. Preparing pipes for the carriage frame

First, we need to cut 4 pieces of the profile pipe, their length must be exactly the same. We also measure each piece of pipe with a ruler for curvature. We either align the curved pipe or do not use it, otherwise the carriage will not work correctly.

Next, we outline the places and drill holes, they should all be drilled at right angles and in clearly defined places. The author uses a drilling machine for drilling. Holes are needed for bolts that will tighten the entire structure, and on which the bearings will be.

At the end, all 4 pieces of the pipe are well painted from the can so that the structure does not rust.

Step Two Hinge

We manufacture a hinge to which a handle with a fixed grinder will be attached. There should also be no backlash in this assembly. We use two ball bearings, press them into the housing from a piece of pipe.The author cut the pipe along so that the pipe tightly squeezed the bearings. Between the bearings we put a sleeve made of a brass tube or other metal.

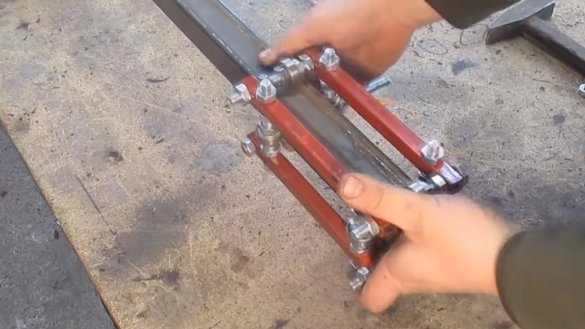

Step Three Carriage assembly

We assemble the carriage, here you will need bolts and nuts. As for the nuts, it is better to use those that have a retaining plastic ring, such nuts themselves will not loosen and the adjustment will not fail.

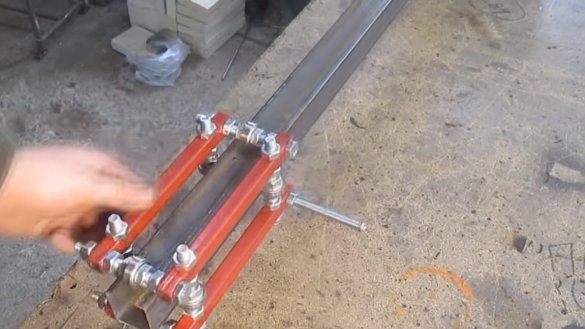

Further, the carriage is adjustable on a square profile pipe with dimensions 40X40. However, it is possible to completely adjust the carriage for a rectangular shaped pipe. The most important thing is that the pipe is smooth, otherwise the cut will turn out to be crooked. The hinge assembly can also be installed on the prepared axle of the carriage; we clamp the bearings with a nut and washers.

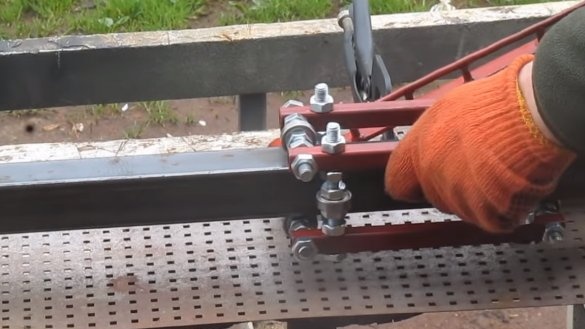

Step Four Grinder holder

We make a reliable holder for the grinder, the author himself welded the bracket from iron plates. The fixture is fastened in three places, it is screwed with two bolts, and in addition the grinder is fixed with a metal clamp.

Prepared fasteners through a piece of the corner of the sludge plate are welded to the hinge of the carriage. It is important that the grinder is fixed rigidly, and nothing springs, we reinforce the beam with bars as much as possible.

Step Five Assembly and testing

We assemble the carriage, we fasten the profile pipe clearly horizontally. The homemade product is ready, it cuts the machine perfectly, now it will not be a problem to cut a sheet of metal evenly. This is the end of the project, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!