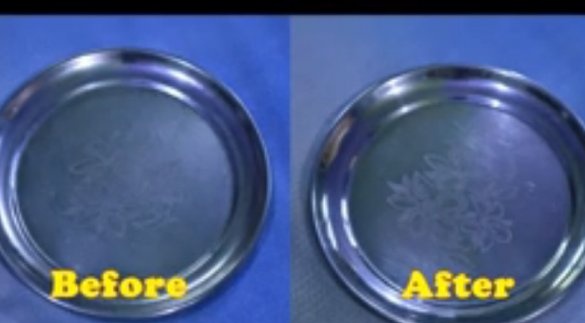

Easy to manufacture and use, the polisher was invented and manufactured by the Master. With the help of this fixtures You can clean the faucet, sink or polish a metal plate.

So, to make the machine, the Master used the following

Tools and materials:

-Metal spray can;

-Sponge;

- DC motor 12V;

-Power Supply;

-Glue gun;

-Drill;

-Plastic cover;

-Attachment to the motor shaft;

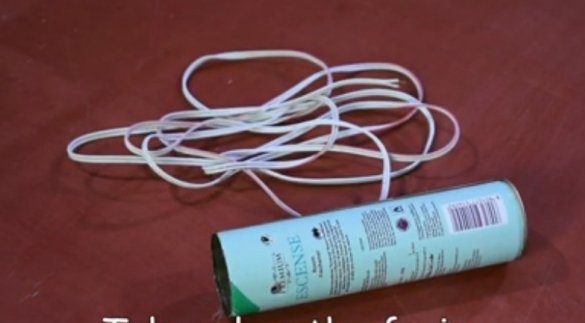

-The wire;

-Screwdriver;

-Power button;

Step one: spray can

First of all, the master cuts off the upper part from the spray can. Then he drills several holes in the cylinder. In the bottom for the wire, on the side surface for the button and for mounting the motor.

Step two: electrical part

Then the master pulls the wire through the hole in the bottom of the can. The ends of the wire are soldered to the motor contacts.

Mounts the power button.

Fixes the button and the engine with hot melt adhesive.

Step Three: Protective Cover

From a plastic cover makes a protective cover for the engine.

Step Four: Sponge

A sponge adheres to the nozzle. Sponge cuts in the desired shape. Screws the nozzle to the shaft.

Step Five: Connect

Connects the tool to the power supply.

Checks the work of the polisher.

Now you can apply water and detergent to the sponge and start cleaning.