I welcome fans to craft, today we will consider how to make a durable and very sharp culinary knife-hatchet. With this knife, you can perfectly chop the greens and not only, but also the knife is so sharp that they can thinly chop the tomato and other products. As a material, the author used steel grade 8670, which can be hardened to high hardness. The knife is made without forging, but the blade is hardened and etched in ferric chloride. Looks homemade excellent and just fire in business, if you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- plate steel grade 8670;

- G10 for linings;

- decorative screws.

Tool List:

- furnace and oil for hardening steel;

- tape cutting machine;

- milling machine;

- paper, pencil, scissors;

- belt grinding machine;

- drilling machine;

- fine sandpaper;

- reagents for steel pickling;

- tumbling machine;

- .

Homemade manufacturing process:

Step one. Knife profile

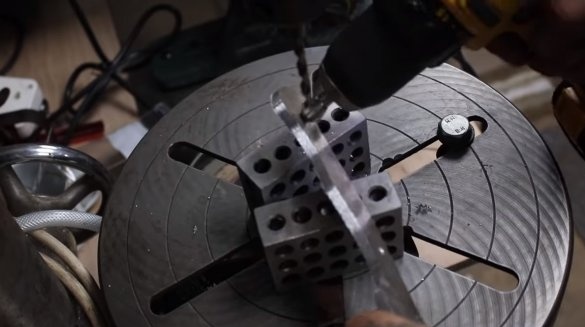

Until the steel is hardened, it will be easy to process. The author cut the profile of the knife with a tape cutting machine, but if desired, you can handle it with a hacksaw.

In the upper part of the blade, closer to the butt, there is a gap, it has rather a decorative character. To make such a gap, the author used a milling machine.

At the end, the author trimmed the knife profile with a belt sander.

Step Two Holes

In the area of the handle, we drill holes depending on the diameter of the pins. For everything to hold firmly, the pins should go in with a small gap and should not hang out. The author used decorative screws instead of pins, as a result, the pads will hold tight, you will not need glue, and if necessary, the pads can be replaced.

Also, the author modified the slotted slot in the blade with a file. Then hardening is to be done, which means that it is time to finish all work with steel, after hardening it will become very hard.

Step Three Quenching

We temper the blade, heat it to a red glow and immerse it in oil. After quenching, the author checked the steel with a file with a strength of 65HRC, there are no scratches on the blade, which means that the steel has a hardness of at least 65HRC. Of course, after the holiday, the steel will become a little softer, but it will spring and will not be brittle.

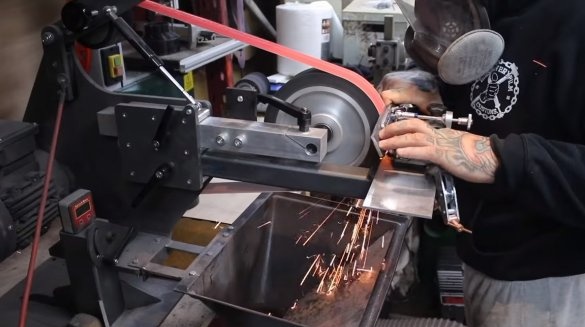

Before the vacation, we grind the blade on a tape machine so that the color of the oxide film is visible.Well, then we heat the steel at a temperature of about 200 ° C and wait for the appearance of an oxide film of straw color. Of course, the color of the oxide film may vary depending on the particular steel grade.

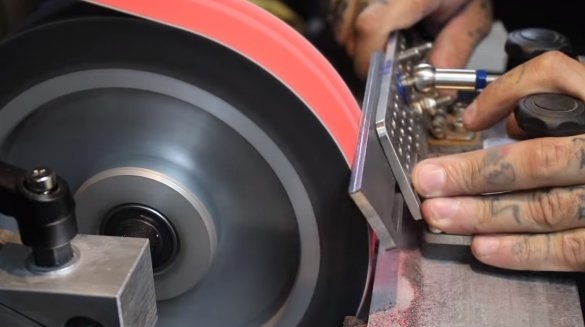

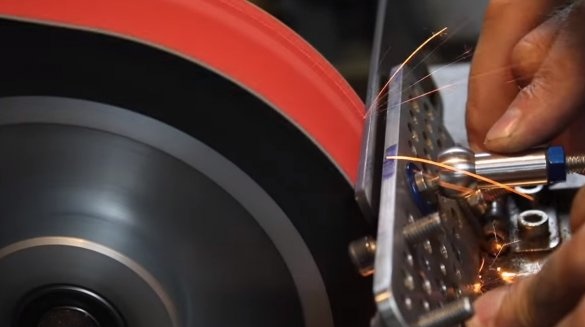

Step Four Bevels

We will form the bevels on the blade, a lot of grinding work will be required, and given that the steel is hardened, you can not do without a belt grinder. Note that hardened steel must not be overheated, otherwise deep tempering will occur with loss of hardness. Regularly cool the blade in water as it is polished. The author used a special clamp for fixing and grinding the blade at a given angle. At the end, we carefully grind the blade with fine sandpaper with water to remove gross scratches.

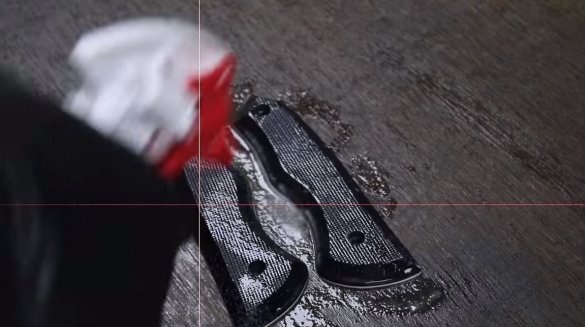

Step Five Lining

Let's make two pads for the handle, the author used the G10 as a material. An indisputable plus of such a material is that it is not afraid of water, acids and other aggressive environments, and the G10 also looks great and is durable. We cut two workpieces with a jigsaw or on a tape cutting machine, well, and then install the parts on the decorative screws on the knife. We perform grinding, adjust the handle in shape and form the desired profile. At the final stage, it remains to polish the pads well with fine emery cloth and polish if desired.

Step Six Steel processing

According to the author’s idea, the knife has a dark color with scuffs, the homemade look looks pretty interesting. To obtain this effect, we poison the steel in ferric chloride until a dark coating is obtained. Next, the blade is washed with soda to neutralize the reagent.

In the end, it remains to throw the knife for a while into the tumbling machine. The author made the tumbling himself, from a piece of sewer pipe, and we use pebbles as an abrasive. The larger the stones, the rougher the scratches on the knife will be. For a more even pattern, you can add coarse sand.

Seventh step. Sharpening

Good hardened steel can be sharpened to a razor condition, and the blade will keep sharpening for a long time. For fine sharpening, you need Japanese water stones or a machine based on them. We start with a large-grain stone, constantly water it with water. Well, then we turn to an increasingly smaller grain and as a result, the blade turns out like a razor. With this knife, you can easily shave your hair, the author cuts thin paper with it.

Step Eight. Assembly

We assemble the knife, the pads are attached to the handle with the help of decorative screws. In order for the pads to look beautiful, they can be polished, or coated with oil, varnish, a thin layer of epoxy and so on.

That's all, now the knife is ready, it looks great, any cook will approve such a tool. The project is finished on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!