Hello fans to craft, I propose to consider homemadewhich will keep your lawn in a neat condition. It's about a small lawn mower that can be made from the motor from an old washing machine. Such engines are not particularly resourceful, but high-torque, which allows you to successfully mow grass with large-diameter knives. Mowing at low speeds is due to the large angular speed that a large-sized knife develops. The assembly design is very simple and reliable. Of the main observations, only the absence of a protective cover over the engine can be noted. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- thick sheet steel;

- motor from the washer;

- a steel plate for a guard;

- a piece of good steel for a knife;

- small wheels;

- pipe or fittings for the handle;

- cable, switch.

Tool List:

- welding machine;

- grinder;

- roulette;

- tools for threading;

- puller for pulley.

Homemade manufacturing process:

Step one. Foundation preparation

First of all, we will prepare the basis, for this you will need a piece of thick sheet steel. The base must not bend and the motor must be securely fixed to it. We clean the base well and trim the excess with a grinder. You will also have to cut or drill a hole under the motor shaft and body protrusions, if any.

Step Two Finalization of the engine shaft

Remove the pulley from the motor shaft, if the motor is old, the pulleys can sit quite firmly, especially if the pulley is made of metal. The author used a puller and heated the pulley with a gas burner so that it could be removed.

After removing the pulley, we cut the thread for the nut on the shaft, which will hold the knife. Such work is best done by two, one should hold the shaft with an adjustable wrench. Also, under the shaft, you need to pick up a sleeve, a tube of a suitable diameter is suitable.

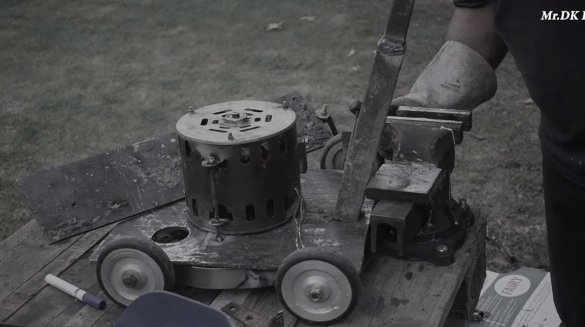

Step ThreeBase engine mounting

The author installed the motor on the basis of a fairly simple and reliable. By welding, we weld the engine mount brackets to the base. If there are no such fasteners, we fasten the motor with bolts and nuts.

Step Four Knife

We make a knife for a lawn mower, for this you need a piece of a steel plate. Steel from an old hand saw is quite suitable, but you can try to adapt a circular disk on a tree of large diameter. We sharpen the edges of the plate and drill a hole under the motor shaft in the center. Note that the hole must be clearly in the center, otherwise vibrations will occur.

Step Five Wheels

We install wheels on the lawn mower; the author simply welded the wheels to the base. The wheels are suitable for children’s bicycles, strollers or even large-sized children’s toys. It is important to weld the wheels correctly in order to get the necessary clearance between the ground, do not forget about the shield.

Step Six Shield

Be sure to make a shield around the knife so that stones and other dangerous objects do not fly into you. Also, the shield will allow you to collect ground grass in the grooves. The shield can be welded from a steel plate of suitable thickness.

Seventh step. Pen and connection

We make a handle for a lawn mower, the author has welded it from a profile pipe. Such an approach is bad in that the structure is heavy, and there is also a danger of electric shock. The handle can be made of a piece of sewer pipe. We connect a cable with reliable insulation and a switch on the handle cases. Instead of a switch, you can adapt the plug with a socket.

After that, the mower will be ready to devour your grass. The homemade product works perfectly, the grass mows without problems and smoothly. Of course, such a machine will not pull high vegetation, but it’s quite possible to trim the lawns with homemade products. On this project can be considered successfully completed, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!