Perhaps some of you were engaged in cutting and drilling tiles with diamond-coated crowns, and they know how difficult this process is. The main difficulty is that such crowns often do not have a center drill.

In this article, the author of the Men’s Craft YouTube channel will tell you how he made the conductors that allow you to perform these works with jewelry accuracy, and without the risk of breaking the crown to the side.

These homemade conductors are very easy to repeat, and will not take you much time.

Materials

—

- Sheet steel

- Machine oil

- Short screws.

Instruments, used by the author.

—

-, metal sheet

—

—

- Cutting and cleaning wheels

—

—

- Drills for metal

- Vise, pliers, file, core, hammer

- Marker, ruler, square.

Manufacturing process.

So, as a basis for this homemade work you will need suction cups to remove dents. The author purchased them in a store, and I found them for mere pennies (about 80 rubles apiece).

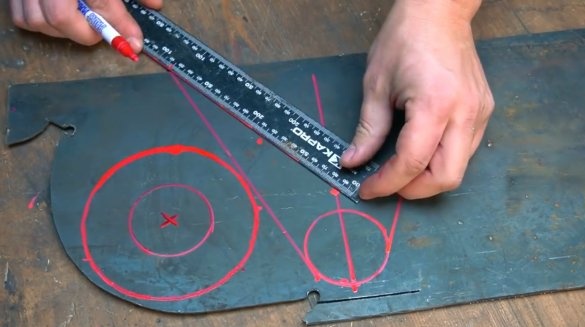

On a steel sheet with a thickness of 1-1.5 mm, the master applies the marking for the first conductor. It will be designed for drilling holes of small diameters.

Then marks the contours of the second, its shape is similar to a dovetail. Using the second one, it will be possible to drill holes with a diameter of more than 20 mm.

It lubricates the cut points with machine oil, and cuts the workpiece along the contour with an electric jigsaw with a metal sheet.

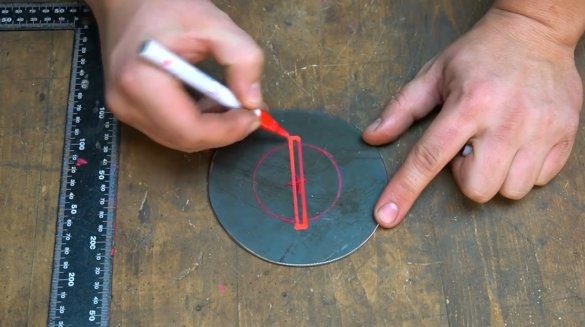

On the first, round billet marks a slot for suction cup clamps.

Cuts excess with a grinder, breaks out the remains with pliers.

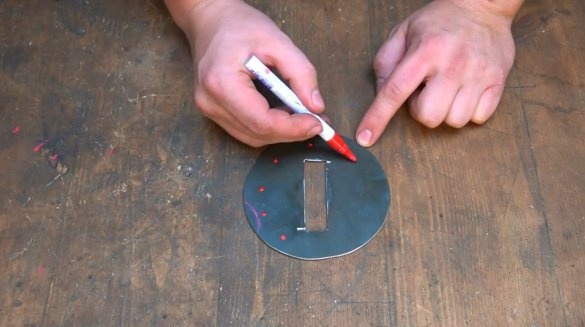

After stripping sharp edges, the workpiece looks like this.

Now the author marks out and kerns several points for the holes for the crowns. He drills holes with a step drill, so he gets nine holes of various diameters.

On the second workpiece (as on the first), it is necessary to drill holes for fixing screws.

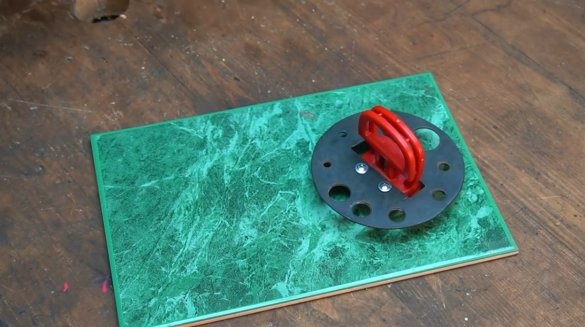

Both steel blanks of the conductors are ready, it remains to attach them to the suction cups with short screws with a wide hat. Of course, before fixing the conductors can be painted with spray paint. But the author left them as is.

That’s all, both conductors for diamond crowns are ready. How does this work?

So, the first conductor is designed for crowns of small diameters. The suction cup is pressed against the surface of the tile, and is fixed on it.The drilling site is watered. The drill is inserted into a hole of a suitable diameter and drilling is performed. If the tile has high strength, then water must be watered constantly.

There is still a small trick that will not constantly pour water to the drilling point. To do this, just make a side of plasticine, and fill the "bath" with water.

Yes, you can do without a conductor. To do this, experienced craftsmen begin to drill at an angle, and then align the drill. But with this method, the risk of breaking the drill, and, accordingly, damage to the surface of the tile, is very high. A tile is also quite sky-high cost.

With the second conductor all the same, it is fixed near the drilling site. Here the master offers his wise advice. You can insert a piece of foam in the center of the crown, and soak it abundantly with water. Then there will be no need to water the drilling site. She will independently fall into it from foam rubber.

Drilling even such diameters is very comfortable. It is enough to rest the crown in the fork of the conductor.

As you already understood, such conductors are suitable for drilling with crowns of any materials with a smooth surface.

In the next article an improved version of such fixtures. With its help, it will be possible to drill holes of any diameter, and also the problem of cooling the cutting edges with water has been solved.

Perhaps some will say that it is necessary to make a platform with holes close to the tile - thus, accuracy will be higher. In this case, the diamond coating on the outside of the crown skirts will be destroyed.

I thank the author for a simple but useful device for drilling tiles!

All good mood, good luck, and interesting ideas!

Author video can be found here.