In the past articleThe author of Men’s Craft’s YouTube channel told you about conductors for drilling tiles and other hard materials. He improved the design, now he has a bath for filling with water. Now there is no need to water the drilling site, cooling the cutting edges of the crowns.

In addition, such a conductor can be used for crowns of any diameter.

This homemade product is quite simple to manufacture, and will not take you much time.

Materials

—

- Sheet steel

- Old slate

- Wing nuts, M6 screws

- Second glue.

Instruments, used by the author.

—

- Cutting, and petal stripping discs

—

- Drills for metal

—

—

- File, marker, ruler, square, core, knife.

Manufacturing process.

So, the author will use the old saw blade from the circular saw as the base base of the conductor. Here, the quality of steel does not play a special role, you can take any steel sheet. The master marked, and cut off the outer parts of the workpiece in the form of a rhombus.

With the help of a petal stripping disk, I processed sharp edges.

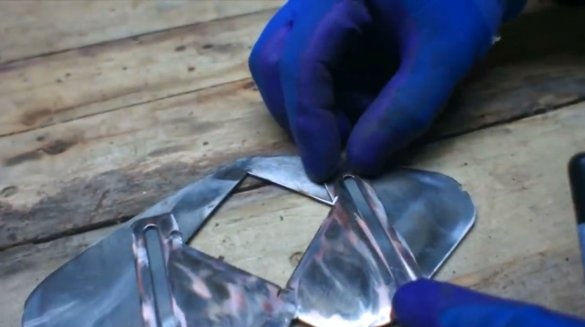

Then you need to cut the hexagon inside the workpiece, while two opposite edges should be 90 degrees. Edges are filed.

From a piece of steel plate, the author cuts out the next part of this shape. This will be the reciprocal movable plate.

After cleaning the surfaces of the workpieces, it is necessary to mark and drill holes for the clamping screws.

The clamping screws are welded on the back of the main plate.

Suction cups are disassembled and screwed to the bottom of the base.

The clamping lever is installed in its place, and is fixed with a pin.

The master decided to use the old slate as a sealant for the bath. He carves a hexagonal section from it.

The seal is glued to the bottom fixtures using second glue.

The adjustment plate is mounted on the screws of the base, and pressed with wing nuts.

As already mentioned in the previous article, it is possible to drill with crowns without a conductor, making the first entrance at an angle, and then aligning the crown vertically. But there is a very high risk of a drill popping off and damage to the surface of the tile. And the cost of some instances of porcelain stoneware can reach several hundred thousand.

So, the conductor is installed on the tile in the right place, the clamping levers are parted in different directions. The required amount of water is poured into the bath.

The crown is installed at the drilling site, the adjustment plate moves to the crown skirt, and is fixed with wing nuts. Do not tighten the crown skirt, it should have a slight backlash.

Water should be poured into the tank only after adjusting and aiming the drilling site, because it may be necessary to move the jig.

The second, small corner on the plate is designed for drilling with small diameter crowns.

In addition, this conductor can be used on vertical surfaces, but in this case, the shale seal must be replaced with a piece of foam, and it should be moistened with liquid.

In the manufacture of this homemade product, you can do without a welding machine, simply by gluing the clamping screws to the second glue, or cold welding.

I thank the author for the simple but very useful idea of the design of a universal conductor for crowns!

All good mood, good luck, and interesting ideas!

Author video can be found here. It also describes methods for making two more homemade products, but articles on similar devices are already on the site.