In this article, the author of The Wood Whisperer YouTube channel tells you about an alternative way to temporarily join blanks.

Many of you constantly use double-sided tape in everyday life, at work and in the workshop. The author also sinned this, until he discovered a more perfect method of gluing two planes.

Materials

- Insulation or masking tape

- Two-component second glue

- Sheet plywood, boards.

Instruments, used by the author.

- Scissors.

Manufacturing process.

The fact is that double-sided tape is extremely sticky and leaves traces that are very difficult to remove.

In addition, when peeling off this adhesive tape from the wood, you remove with it some of the wood fibers, leaving quite noticeable bald patches.

The author often has to attach the template to the workpiece. Before you cut the material according to the shape of the template, you need to securely fasten both surfaces in order to avoid their displacements relative to each other.

And the craftsman invented his way of gluing - with the help of a blue insulating tape and two-component cyanoacrylate adhesive.

Let's look at the results.

When working with double-sided tape, the master usually cuts two pieces and sticks them along the edges of the workpiece. This material is sensitive to pressing: the more you rub it into the surface, the better it sticks. If you have, even small, nails, then it will not be difficult for you to remove the protective film. True, sometimes you may be disappointed - it may turn out that this film will not be so easy to remove. It depends on the manufacturer.

Then the template is attached to the base and pressed properly. The part undergoes the necessary processing, after which the template is peeled off, and pieces of adhesive tape are removed. In 90 percent of the 100, sticky residues will remain on your workpiece.

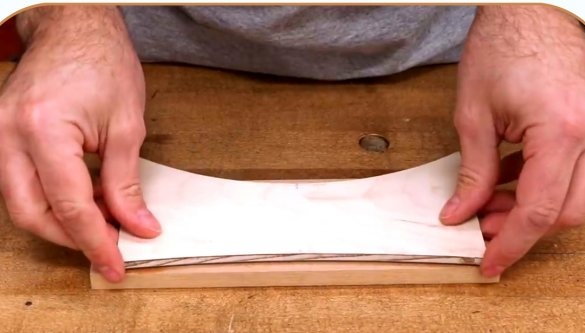

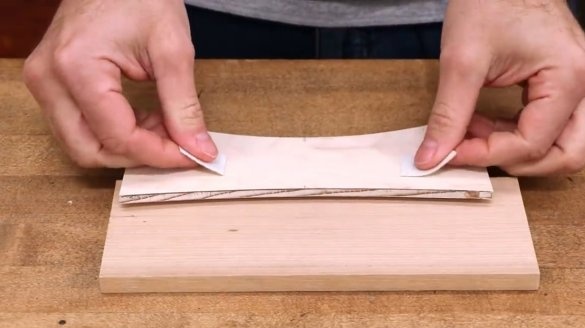

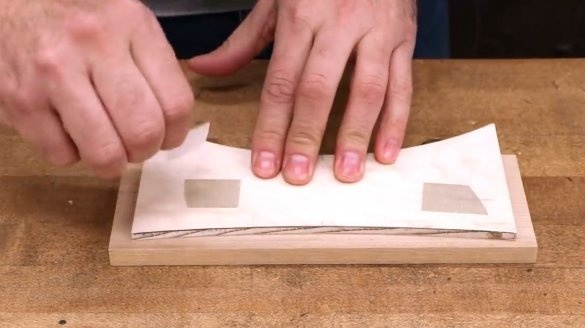

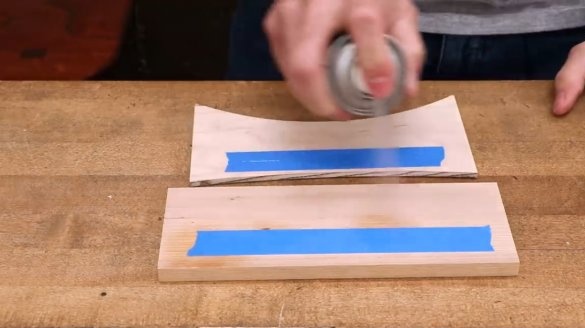

Now let's see how the blue electrical tape will behave. The main trick when working with it is to place both pieces of tape in a symmetrical position relative to each other. The adhesive should only be on the surface of the tape and in no case should it get on the wood!

The author squeezes a few drops of second glue on one strip of tape and a little hardener on another.

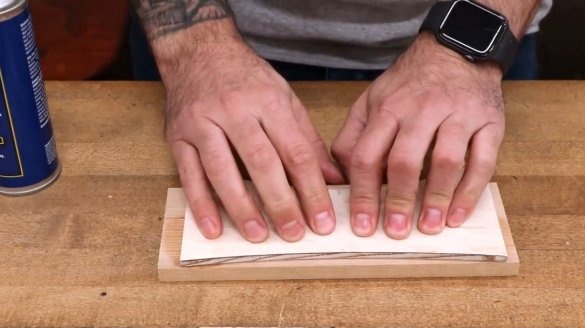

After that, he presses both parts and holds them under pressure for several seconds. Items are linked.Of course, a more rigid and reliable connection occurs with double-sided tape, but in most cases it is not necessary.

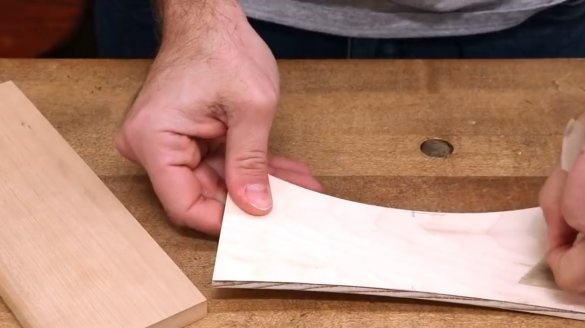

In the case of second glue, it turns out to be much easier to open the glued elements and, take a look for yourself, - no traces! Everything is clear.

Thanks to the author for a simple and useful way to temporarily join parts!

All good mood, good luck, and interesting ideas!

Author video can be found here.