For the village or cottages just can not do without such an indispensable thing as a machine. With it, you can always sharpen a shovel or ax. Also, it is possible to process various materials on the machine, for example, to grind some element for homemade. The article will consider an example of how to make a powerful and durable sharpening machine do it yourself. As a power element, the author used a 750-watt engine.

Materials and tools for manufacturing:

- welding;

- grinder;

- drill;

- pulleys (on the motor and on the shaft);

- belt;

- shaft (the author ordered from a turner);

- bearings for a shaft;

- a corner, metal plates to create a machine body;

- electric motor (750 watts / 1500 revolutions are used);

- control buttons, magnetic starter;

- paint, bolts with nuts and other trifles.

The process of manufacturing a grinding machine:

Step one. Shaft for the machine

The machine shaft must either be searched in the market or ordered by a turner. There should be a pulley on the shaft, the shaft itself is on two bearings. There are special places on both ends of the shaft for grinding wheels.

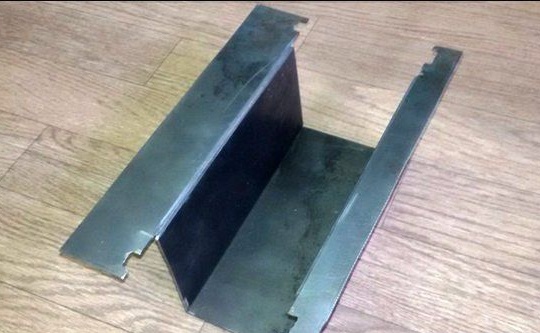

Step Two Body for machine

For the manufacture of the body you will need corners, metal plates, welding, a grinder and other elements. The frame must be such that it can be installed on the shaft, as well as fix the engine. In the photo you can see how the author did it at home.

The engine is mounted on a metal plate, it is securely fastened with screws and nuts. It is advisable to use a grower.

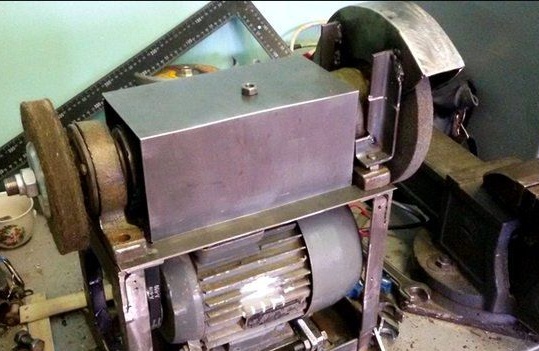

Step Three Final build phase

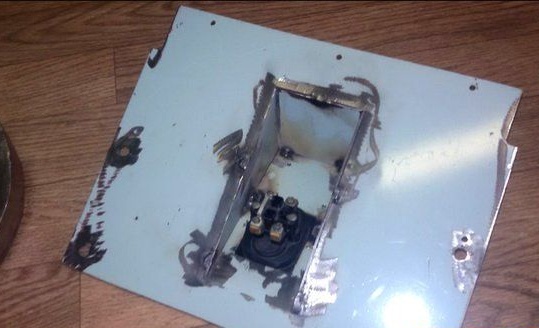

After the engine and shaft are installed, as well as a belt on the pulleys, you can already start the homemade work and see how it works. If everything is fine, you can proceed to install electronics and control devices in the case. The frame needs to be sheathed with metal sheets. On one sheet there will be a magnetic starter, as well as buttons for turning on the device. For these purposes, a special case is made.

It is also important to make safety guards, circles and armrests. It is also desirable to cover the shaft, for this purpose you can make a special shield.

Well, that’s all, now in full assembly everything can be checked. If everything works fine, now you can paint the homemade product and then enjoy the work of this beautiful and very useful device. For complete safety, the machine can be grounded.