Surely many of the masters were faced with the need to cut various synthetic materials such as plastic, organic glass, acrylic, or fabrics. This is often a very problematic process.

In this article, the author of the KJDOT YouTube channel will tell you how to facilitate this procedure with the simplest hot knife that he will make on the basis of an ordinary soldering iron.

This homemade job takes literally a few minutes tohome conditions.

Materials

- Screw M5

- Blade for clerical knife

- Sheet acrylic, plexiglass

- Kapron tape.

Instruments, used by the author.

- Hacksaw

—

- Vise, pliers, screwdriver, scissors.

Manufacturing process.

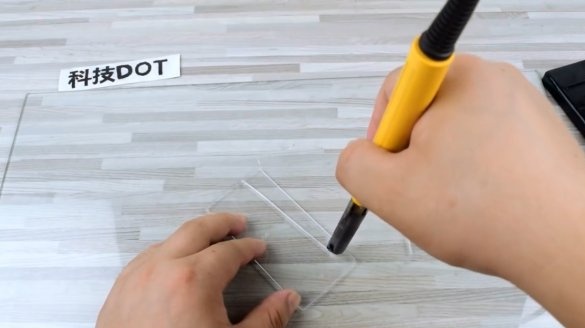

So, the master will use a standard soldering iron with a power of about 70 watts as the basis for this homemade work.

The first step is to unscrew both clamping screws, and remove the standard sting.

Next, you need to tighten the M5 screw in a vice, and saw it along with a hacksaw. Enough sawed into two-thirds of the length of the screw. The author used a screw 40 mm long. In each individual case, it is necessary to select the diameter of the screw and its length corresponding to the dimensions of the heating element of the soldering iron.

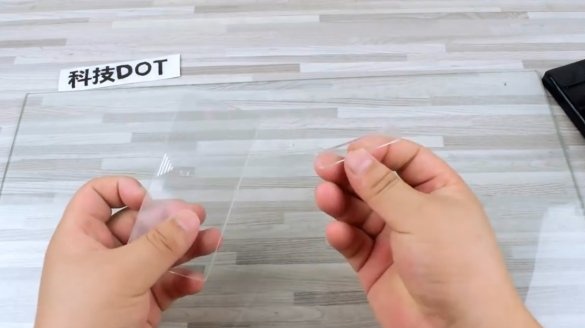

Now you need to use a pair of pliers to separate one section of an interchangeable blade for an office knife. If its width is greater than the internal diameter of the hole in the soldering iron, then the edges of the blade should be cut off with a grinder.

The screw is inserted into the head of the soldering iron, and a blade is installed in the slot of the screw. Now you just need to tighten both side clamping screws with a screwdriver.

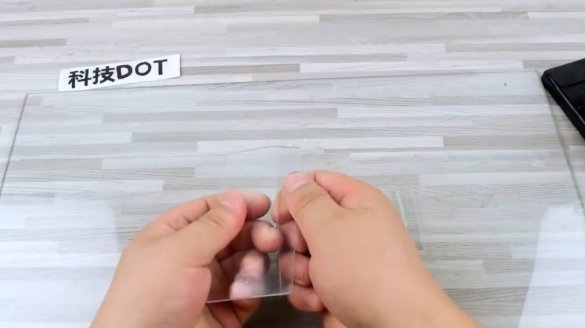

That's all, just plug the tool into the network and wait for the blade to warm up. Of course, it is advisable to have a temperature-controlled soldering iron. After that, you can cut sheet acrylic.

It is also easy to cut very small workpieces. The seam after the cut is slightly soldered, but it is very simple to break it.

Foamed polyurethane is cut even easier.

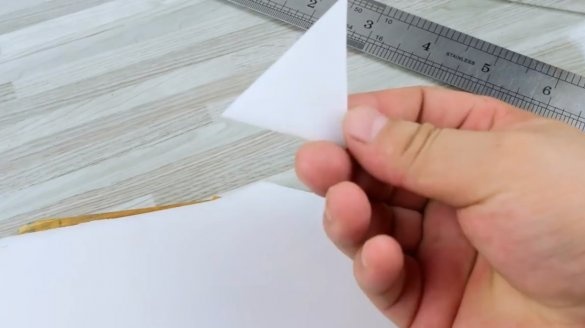

And here is an interesting experiment. All of you know how a kapron tape or thread behaves after cutting it. Its edges simply fluff, and bloom.

Of course, this can be fixed by melting the edges of the cut with a lighter. But when using a hot knife, these actions are no longer required.

Such a knife copes with a plastic bottle just fine. You can perform almost any curly cut.

To return the soldering iron to its working position, just release the screws and replace the knife with a standard tip.

Thanks to the author for the very simple idea of a hot knife design! It will be useful to many masters both in the workshop and in everyday life.

All good mood, good luck, and interesting ideas!

Author video can be found here.