good afternoon friends the inhabitants of our site! I want to share with you how easy it is to make a wood burning device do it yourself. For this homemade work we will need the following materials and tools.

It: step-down transformer, with a voltage on the secondary winding of 4V, and a current of at least 2–3 amperes, a power cable with a plug - 1 m long, and a power cable with a cross-section of at least 0.75 mm, two meters long; to connect to the handle of the burner; a small wooden lath measuring 1 * 2 * 15cm, you can use plywood; wiring terminals - 2pcs; electrical military clamps for connecting the terminals of the secondary winding of the transformer -2pcs; any nichrome wire from any heating element; electrical tape, toggle switch.

Of the tools you will need: wood hacksaw; soldering iron, solder, tweezers, wire cutters, pliers, screwdrivers, small screws and cloves.

We assemble as follows:

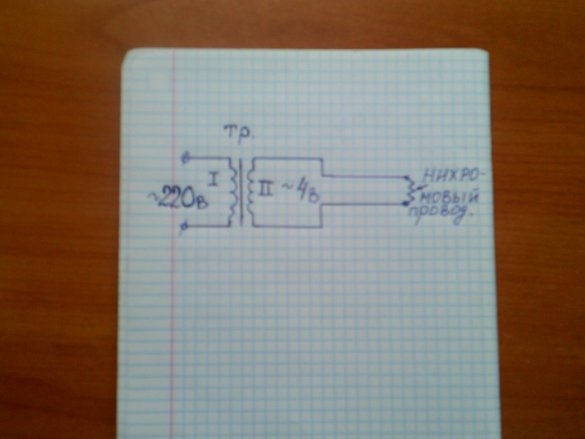

The connection diagram is shown in the photo.

Step 1. We check the transformer for operability, for which we find the network winding, connect it to a 220v network, and measure the voltage on the secondary winding - it should be about 4-5v.

Step 2. From a scrap of plywood or a board we cut the rail of the above sizes. We process its edges, make them semicircular.

Step 3. We attach two mounting terminals to one end of the obtained handle using self-tapping screws, as shown in the photo.

We attach to the outer ends of the terminals a piece of nichrome wire, 2.5-3 cm in size, we select empirically (we make sure that the wire is heated to a bright cherry color, and does not burn out). To the opposite ends we connect 2 meters of a network stranded wire. The second ends of the wires are connected through mounting clamps to the secondary winding of the transformer.

Pressing the wire to the wooden handle, wrap it with electrical tape, as shown in the photo.

We connect the mains cable with the plug to the primary winding of the power transformer through the toggle switch.

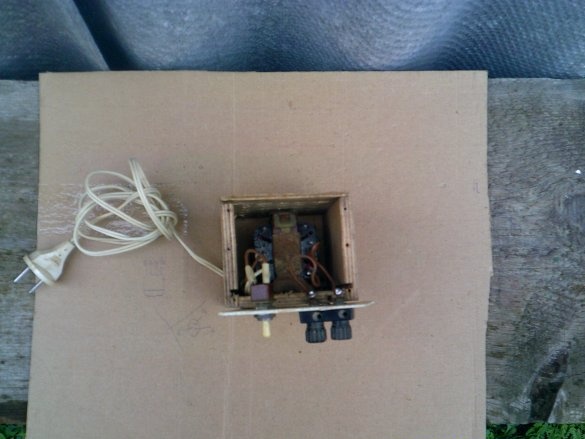

Step 4. From plywood or any other material we make a suitable housing size. We place the assembled homemade product in this case.

Next, we check the operation of the burner by connecting the power cord to a 220v network. With this homemade product you can do good crafts, and even the paintings, having previously applied the drawing we need on the processed plywood sheet.

That's all, the homemade product is ready. I wish you all success in your work. See you again.