I welcome fans to craft, I propose to consider homemade, which will facilitate the work of a blacksmith and not only. It will be a question of a small blacksmith hammer, which the author built on the basis of an old electric meat grinder. With such a hammer, you can easily undo a steel rod, reinforcement, flatten the pipe and perform various other tasks where large impact forces are not required. The construction of the homemade product is quite simple, the hammer is raised with the help of an eccentric that rotates the combine. If the homemade product interests you, I suggest studying the project in more detail!

Materials and tools used by the author:

Material List:

- a heavy hammer without a handle (sledgehammer);

- plywood or sheet steel for the clown;

- Sheet steel;

- spring;

- corner;

- steel plates;

- bolt with nut;

- paint for metal.

Tool List:

- grinder;

- welding machine;

- roulette;

- marker;

- drilling machine.

Homemade manufacturing process:

Step one. The basis for the meat grinder

First of all, we will make the basis for the meat grinder, for this you need a sheet of steel, we weld the stops from the profile pipe or corner on the sides. Of course, you need to secure the harvester reliably, since the loads will be considerable. It is best to fix it with a metal clamp, and you can screw the bottom of the meat grinder, if it is strong.

Step Two Drive shaft

Next, we make a shaft on which we will install an eccentric. As a shaft, the author adapted a screw from a meat grinder, a long nut was welded to its end. Thanks to this nut, we can fasten the cam with a bolt or threaded rod with nuts.

The author wrapped a threaded rod in a long nut, this will be a continuation of the shaft, be sure to make stops under the shaft from thick steel plates.

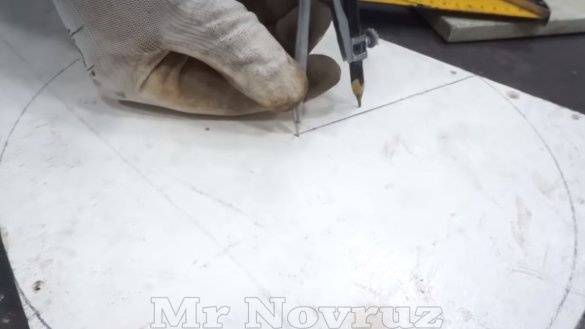

Step Three Cam manufacturing

We make an eccentric for the machine, it will raise our hammer, and the hammer will fall already under its own weight.The higher the hammer rises, the greater the rate of fall will be and the stronger the impact on the anvil will be. The author made an eccentric of plywood. We do the marking, and then we cut the part with a jigsaw, it remains only to polish the part with a grinding machine.

Of course, plywood will not last long, it is better to use a sheet of steel and lubricate the cam. However, plywood can simply be sheathed with a steel plate.

Step Four Installing the hammer and guides

We weld a stand to the base, for which the author used a thick steel plate, at the end of the stand we drill a hole for the axis. The author also welded a thick steel plate to the hammer, and to fix it to the rack he made a fork from the plates. As an axis we use a bolt with a nut.

To prevent the hammer from moving sideways during work, we weld two guides to the base, for this the author adapted steel corners. As for the anvil, the author welded a piece of thick sheet steel at the point of impact of the hammer. Of course, the anvil must have a large mass, otherwise it will spring.

Step Five Painting, assembly and testing

We paint the machine with metal paint so that the steel does not rust, and the machine pleases the eye. Then you can assemble the car, we pay special attention to the meat grinder, it needs to be fixed securely. To further increase the impact force of the hammer, the author adapted the spring. In general, if the motor pulls out, you can put a lot of springs, thereby significantly increasing the impact force of the hammer.

Homemade ready, you can experience. The author heated the steel bar and quickly unchained it without physical effort. Also, the machine splashed a piece of pipe for the author. Of course, the project requires minor modifications, but in general the car turned out simple and useful. I hope you enjoyed your homemade work and found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!