In old washing machines you can find asynchronous motors, they come in different capacities and useful ones come out of them homemade. As a rule, the speed of such motors is low, but they have good torque. Auto decided to make one such motor a good disk grinding machine. Homemade in the assembly is simple, almost everything is made of wood. The machine works perfectly, it is convenient to grind on it when you need to bring out the plane. Of course, the sandpaper on the machine is glued, so you won’t be able to quickly replace it; it would be nice to install Velcro on the disk. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- motor from an old washing machine;

- boards;

- cable;

- switch;

- self-tapping screws;

- bolts and nuts;

- corner;

- carpentry glue;

- sandpaper.

Tool List:

- drill;

- screwdriver;

- jigsaw;

- iron;

- grinder;

- ruler, level, marker.

Homemade manufacturing process:

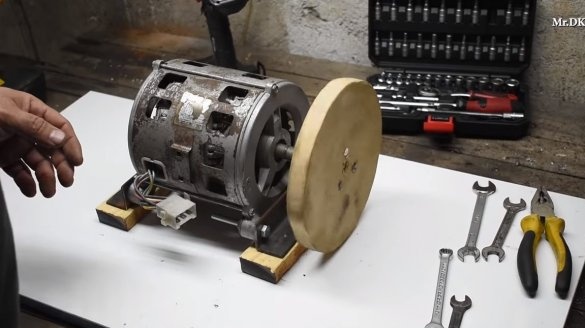

Step one. Bed assembly

First of all, the author assembled the bed, planks, cubes and screws were used. The result was such a little table for the motor.

Step Two Production and installation of a disk

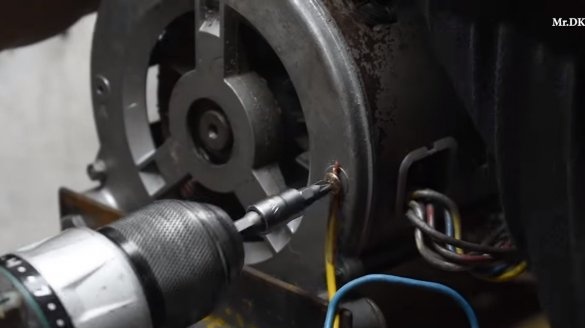

The author also cut the disk from a wide board using a jigsaw. To fasten the disk to the motor shaft, we drill holes for the bolts in the pulley, and now the disk can be firmly bolted to the pulley with bolts and nuts. Of course, under the heads of bolts or nuts in the disk, you will need to make recesses, otherwise the protruding parts will interfere with the installation of sandpaper.

Step Three Engine installation and finalization of a disk

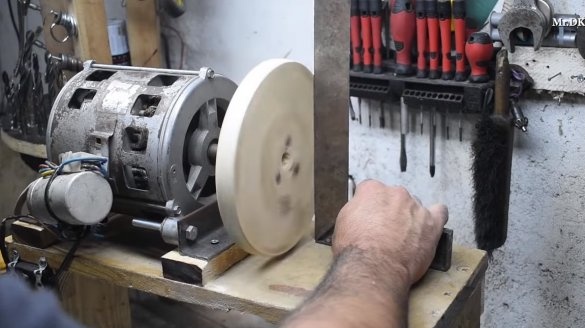

We install the engine on the table through the slats, and also use a steel corner in order to fasten the engine.

After installing the motor, connect it through the switch and start. Next, we need a grinder with a petal disk, we grind the disk with it so that it becomes perfectly round, you can also work with a chisel.As a result, the author got a perfectly round disk, we center the motor so that the disk is clearly vertical.

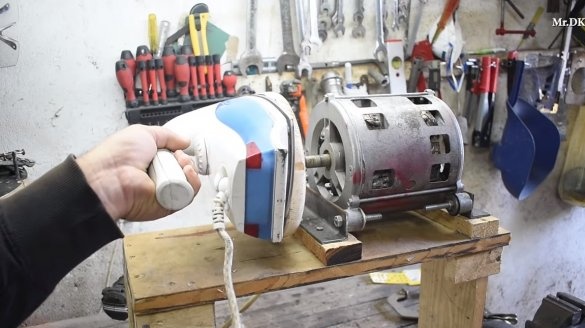

Step Four Sandpaper Installation and Testing

Cut out a circle of emery paper in the shape of a disk and glue it with wood glue to the disk. To speed up gluing, the author used an iron. At the end, we fasten the wooden stop and the machine can be tested. The author made two speeds for the machine, fast and slow. The homemade work perfectly, in the workshop such a machine will definitely not stand idle. The project is completed on this, I hope you liked the homemade work, and you found useful thoughts. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!