I welcome all fans to craft, I propose to consider a drilling machine, which you can assemble based on the motor from an old Soviet washing machine. The author used a rather powerful motor, at as much as 650 watts, such a motor paired with a gearbox gives out a very large torque. The author used the reducer from the 180th grinder. The bed and carriage are made of available materials, mainly sheet steel, pipes and so on. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- the engine from the washing machine 650W / 1350 rpm;

- gear from the 180th grinder;

- corner;

- round pipes;

- Sheet steel;

- bolts and nuts;

- springs;

- switch;

- cable with good insulation.

Tool List:

- ;

- Miter saw;

- ;

- vise;

- ;

- marker.

The manufacturing process of the drilling machine:

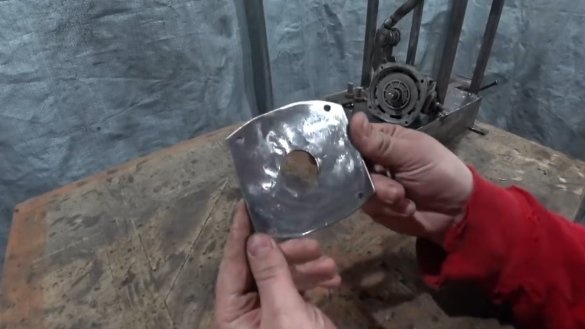

Step one. Gearbox refinement

For the machine you will need a reducer from the grinder by 180, it underestimates the engine speed more than the reducer from the 125 grinder, as a result, we get a higher torque, and the axis in this gearbox is thicker. The author, using a grinder, cuts off a piece of the anchor and knocks the remains of the anchor off the axis. You will also need to cut a piece from the grinder housing in order to screw this part with the bearing seat to the gearbox. If there is no such part, you can weld it yourself from sheet steel, using a piece of pipe as a holder.

Step Two Carriage Making

We weld the carriage on which the engine will be fixed. We make the carriage from thick sheet steel, drill holes depending on the location of the mounting bolts. Pieces of a round pipe are welded to the four edges of the carriage, these will be a kind of "radial bearings" that will slide along the vertical guides.

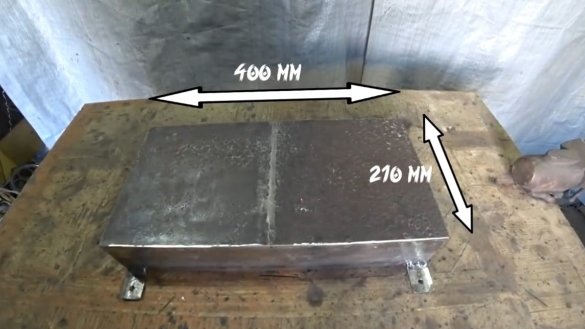

Step Three The foundation

We make the basis for the drilling machine, it should be as strong as possible so that the whole structure does not fall. You can use as a basis a piece of a suitable channel. If there is no channel, it can be welded from thick sheet steel. We weld the ears to the base for bolting the machine to the base.

We also weld 4 racks to the base, these can be pipes or steel rods. First, we insert the rods into the carriage, and then grab to the base. Only in this way will you install the racks correctly.

Step Four Springs

The motor from the washing machine, together with the carriage and the gearbox, forms quite a lot of weight, so powerful springs are needed to lift this whole structure. You can put as many springs as needed for the engine to go up. The springs are attached to the axles and the carriage. The axles are attached with homemade "ears" to the uprights.

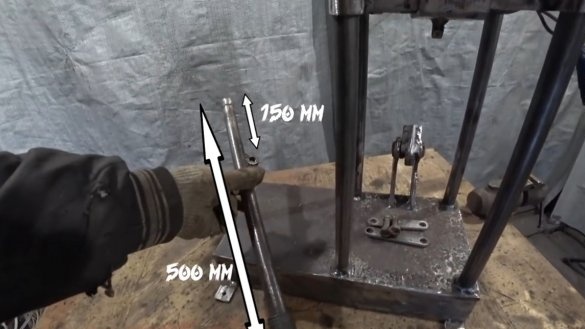

Step Five Lever arm

We make a lever from a steel pipe, this will be the handle with which we will lower the carriage down. We fasten the lever to the base, and also attach the “connecting rod” to the carriage through the hinge. The connecting rod and the arm for the lever are made of sheet steel, we use bolts with nuts as axles. Nuts are best used with plastic snap rings.

Step Six Gearbox installation

We install the gear from the grinder, the gear axis should be opposite the motor shaft. The author made the fasteners for the gearbox from thick steel plates and welded them to the carriage. It remains to connect the axes, for this purpose the author used a piece of hose and two clamps. We use the hose for high pressure, it is reinforced with ropes and can withstand large twisting loads. Such a rubber sleeve can last quite a while.

Seventh step. Final touches and tests

We install a drill chuck on the gearbox shaft to screw the chuck, you can weld a nut for the grinder to it or cut the thread directly in the chuck.

We paint the frame so that it does not rust, now the machine looks great. We put a convenient knife switch to quickly turn off the machine in case of something. The machine is ready, the author put a huge drill in the chuck and drills everything in a row with his monster, starting from wooden beams, and ending with thick sheet steel.

The machine showed itself perfectly, a machine for a real man. On this project is completed, I hope you homemade I liked it, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!