I welcome fans to craft, I propose to consider an interesting design of a grinding machine. The author used a motor from a washing machine, as many masters usually do. But what’s interesting in this car is the frame, it is mounted on the wall, and the motor is able to rotate so that it can be fixed in three positions. Thanks to this design, the machine does not take up extra space in the workshop and you can always choose a position convenient for a particular type of work. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- motor from an old washing machine;

- washers, nut (or ready-made adapter for installing an emery wheel);

- corner;

- Sheet steel;

- bolts and nuts;

- small springs;

- paint.

Tool List:

- ;

- welding machine;

- ;

- ;

- vise;

- drill.

Manufacturing process homemade:

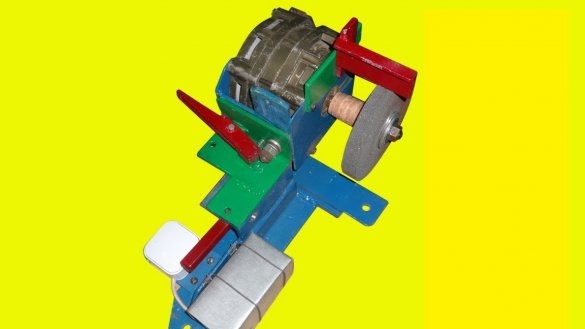

Step one. Bracket for engine

First of all, we need to make a bracket for the engine. In this regard, everything is individual, the bracket is made under the housing of a specific engine. In the front of the bracket, a piece of sheet steel was used, in which the author drilled holes for the location of the engine pins. Other parts are also made of sheet steel, but thicker. To get such plates, the author cut out pieces from the corner.

Step Two Swivel Joints and Lock

we make swivel joints, everything here is already made of a corner. We use bolts with washers and nuts for the hinge axles. The design provides two joints for turning the motor to the desired position.

For each hinge, you need to make a latch, it is a rod that goes into the holes and fixes the hinge in the desired position. We grind the rod from a steel rod or bolt, drill a hole in it, with which the rod will cling to the handle. The handle itself can be made from a piece of a square pipe, be sure to use a spring that will hold the handle with the rod in position.We weld the necessary ears to the hinges, drill holes and make stops under the springs.

Step Three Painting and installation of the engine

We paint all the components of the car, now everything looks gorgeous, you can assemble it. We collect the hinges, do not tighten the nuts so that the hinges rotate easily. Nuts can be used with plastic retaining rings so that you do not have to constantly tighten them.

The finished structure can be hung on the door, but there will be a lot of noise from work, it is best to install the machine on the wall.

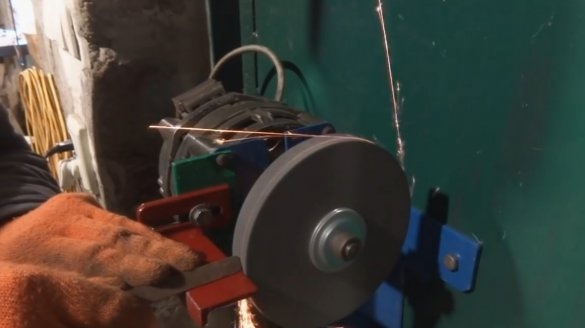

Step Four Grindstone Installation

We start the engine of the engine and with the help of a grinder we grind the axis in the way you need so that you can put a grindstone on it. The author also removed excess metal at the end of the axis and then cut the thread. In the end, the grindstone can be installed on the axis by clamping it with washers and a nut.

The machine is ready, we put a good convenient switch, a cable with good insulation and fasten the emery to the wall, where it will not interfere. The author also made a convenient adjustable emphasis for his grinder. The homemade product works perfectly, it is convenient to use the machine, you can install the engine in one of three positions depending on your needs.

On this project can be considered completed, I hope you liked the homemade product, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!