I welcome all fans to craft, I propose to consider homemadewhich is able to facilitate labor on earth. It's about such a useful thing as a cultivator. Of course, you can buy such a machine, but they cost a lot, and the author decided to adapt a small motor for 50 cubes for homemade work. The cultivator works perfectly, the machine takes even problematic soil with dry clay and stones. And if you come up with a reduction gear, you can install the wheels on the car and use it as a walk-behind tractor or even as a means of transportation. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- two-stroke engine for 50 cubic meters;

- chain transmission for a moped or the like;

- steel axis;

- bearings with cages;

- finished wheel hubs;

- Sheet steel;

- bolts and nuts;

- round pipes;

- profile pipes;

- gas tank;

- paint for metal.

Tool List:

- Miter saw;

- ;

- ;

- ;

- ;

- drill;

- wrenches and stuff.

Homemade manufacturing process:

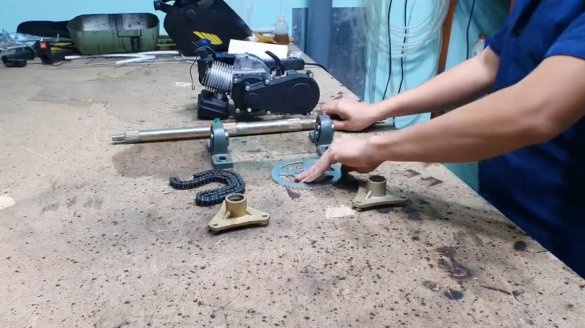

Step one. Production axis

The author used the finished axis for the manufacture of karts and other equipment. If you don’t have such an axis, you can use a car shaft or a pipe with a thick wall. The author had to make the axis shorter, he cut it and then evenly welded it with TIG welding.

A driven sprocket, hubs and bearings in the housings are mounted on the axis.

Step Two Production of knives for a cultivator

First of all, we need to cut two fasteners from thick sheet steel, these will be some kind of disks on which knives will be fixed. As a result, the knives from the walk-behind tractor can be removed by unscrewing the bolts, and if desired, the wheels can be put.

You can make knives, you will need sheet steel, and it is better to take high-quality steel so that the knives serve for a long time. We cut the steel into strips using a miter saw, and then bend in the form of the letter "G". If desired, the knives can be sharpened so that the cultivator works more efficiently. When the required number of knives is ready, we weld them well to previously manufactured parts. That's all, now we have two excellent cutters ready.

Step Three Frame manufacturing

We weld a simple frame under the cultivator, the author used rectangular profile pipes for such purposes. Of course, for such a technique, we choose pipes with a maximum wall thickness, everything should be very strong.

We install bearings in the housings on the frame together with the axle, we fix everything with bolts and nuts.

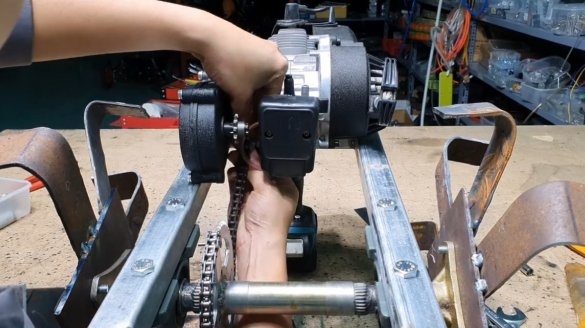

Step Four Engine installation

We make good strong fasteners for the motor, the author used a thick sheet of steel. We drill holes and weld the sheet to the frame. That's all, you can install the engine, and also install the chain.

Step Five Pens

We make handles for a cultivator, in this case we need round pipes. We bend the pipes and weld to the cultivator, we weld a jumper between the pipes. To hold the handles comfortably, you can put pieces of hose on them. Note that the handles can fly off and then the cultivator will have to catch up, it is better to stick them.

Step Six Gas tank and control

We install a small gas tank above the engine level, so that gas easily flows by gravity into the carburetor. We also install the throttle control lever of the engine on the handles, for this you can adapt the brake lever from the bicycle. It will not be superfluous to install an ignition switch on the “steering wheel” just in case.

Seventh step. Painting, assembly and testing

We disassemble everything and thoroughly paint it, it is better to use the soil first. Without paint, all metal quickly rusts from dirt, and the cultivator will be difficult to wash.

We collect everything, refuel the gas tank and you can experience it. The author went to the garden and started working, the machine works fine, there is enough power, but the problem is that dirt and stones flew from under the knives into the author, the problem needs to be solved.

Step Eight. Shields

We make protective shields above the knives so that the earth and stones do not fly at you. The author quickly made shields from sheet metal, we simply bend it into the desired shape around the sides. We make fasteners for guards, they can be made of pipes. We weld everything and now you can safely work on the machine.

The author managed to cultivate a garden not bad, as well as a plot with dried clay and stones, the car did the job. Now on such soil you can grow excellent vegetables. Of course, little will grow on pure clay, so fertilizers will need to be applied. The project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!