The master assembled this milling machine mainly from the material that he had available.

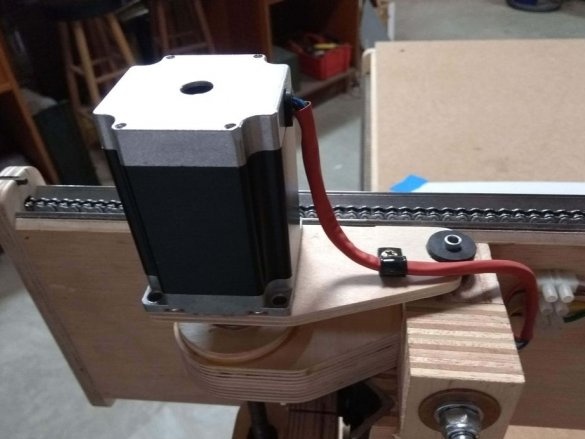

This is a classic three-axis milling machine. It has a portal that moves along the length of the base (Y axis). There is a carriage on which the router is mounted, and it moves back and forth (X axis). And there is a mechanism that raises and lowers the router up and down (Z axis). For movement, the master uses stepper motors and chains. For linear rails, steel V bearings are used that extend over a steel corner. The wizard does not give detailed instructions, only the general concept and ideas.

Tools and materials:

- Bedside table;

-Door;

-Rollers;

-Metal corner;

-Plywood;

-Fasteners;

-Drill;

Milling cutter;

-Saw;

-Wire;

-Chain;

-Threaded rod;

-Step engines;

-Stars;

-Bearings;

-Adapter for a vacuum cleaner;

-Arduino;

- Estlcam controller;

-Solid state relay;

-Power Supply;

-Step drivers;

Step One: The Table

The master redid the table from the old nightstand. As a countertop, the master nailed a wooden door to the table. Below were installed rollers.

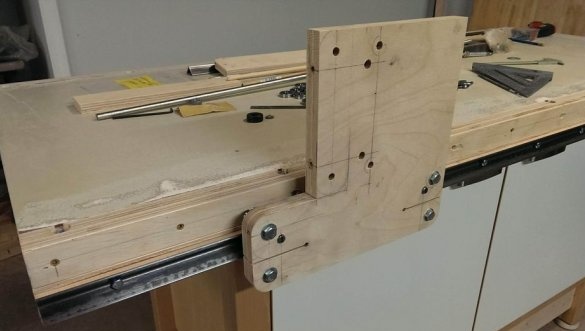

Step Two: Rails

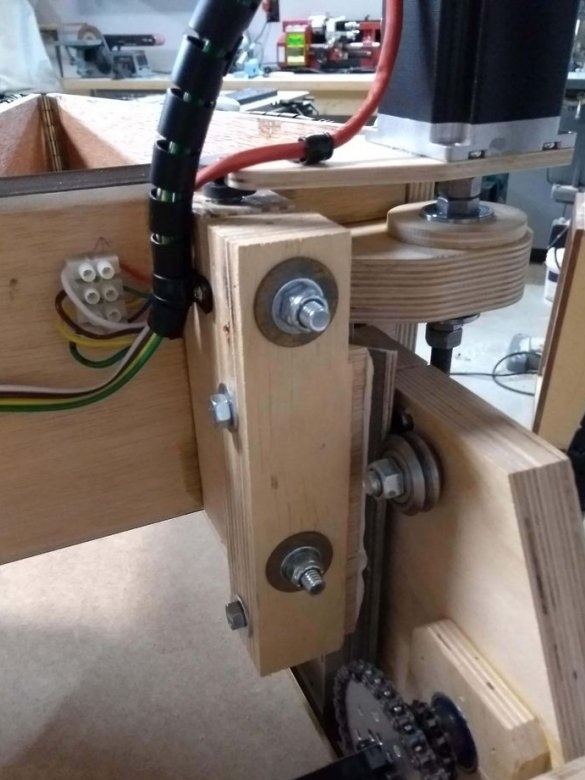

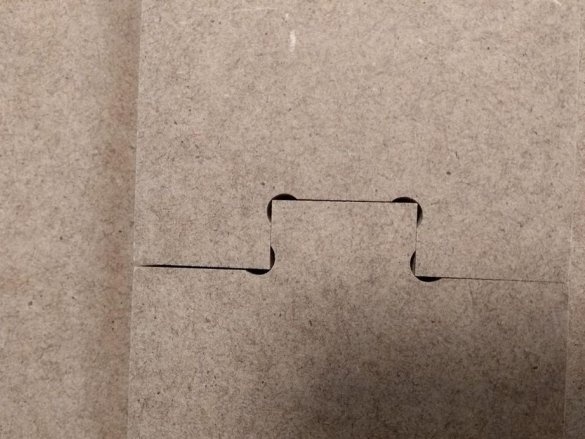

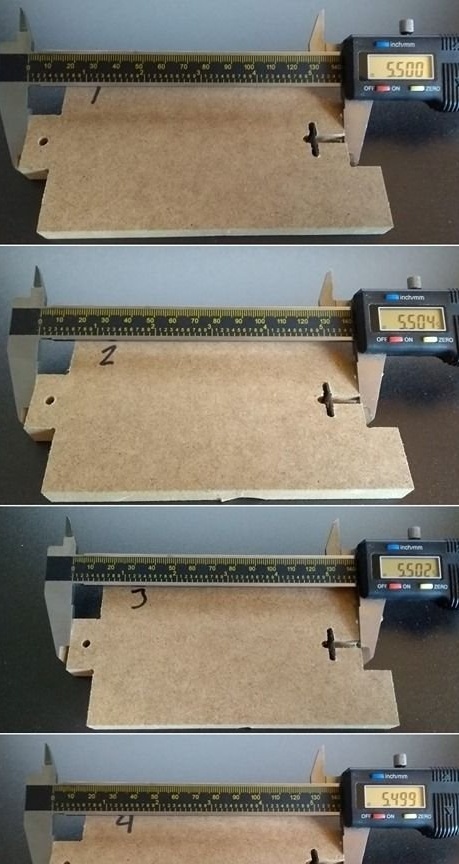

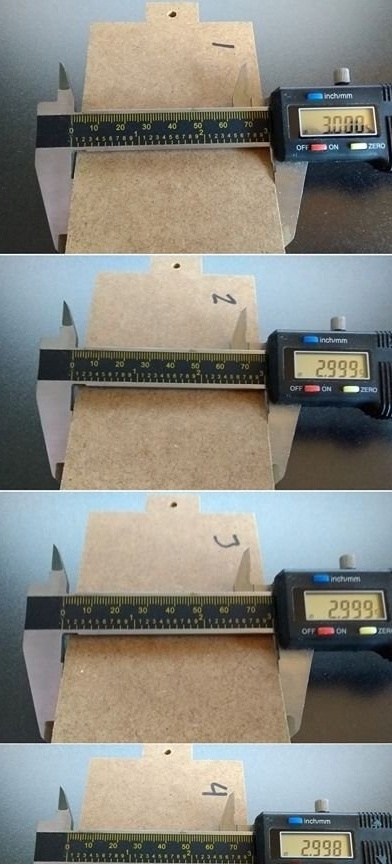

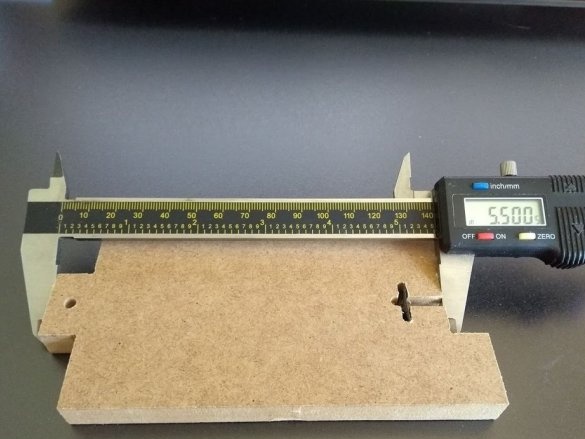

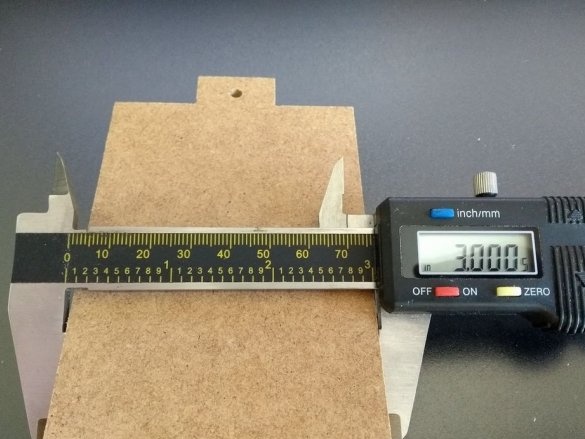

The master uses a metal corner as a guide. On the plywood blank, the master fastens four bearings with a groove. It is clear that the corner is attached on both sides of the table.

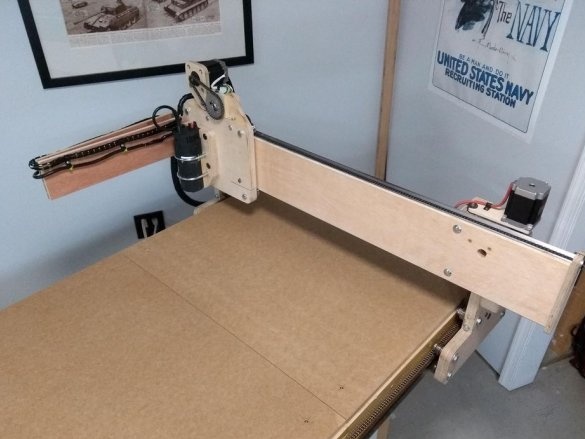

Step Three: Portal

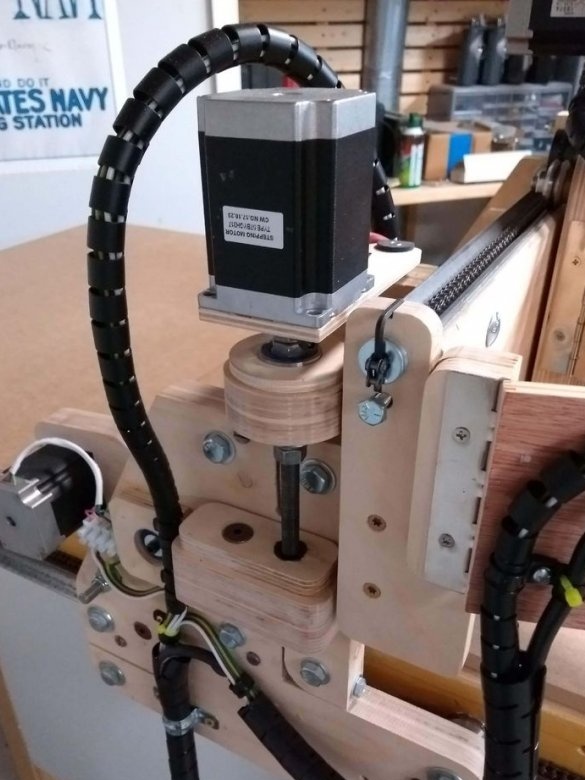

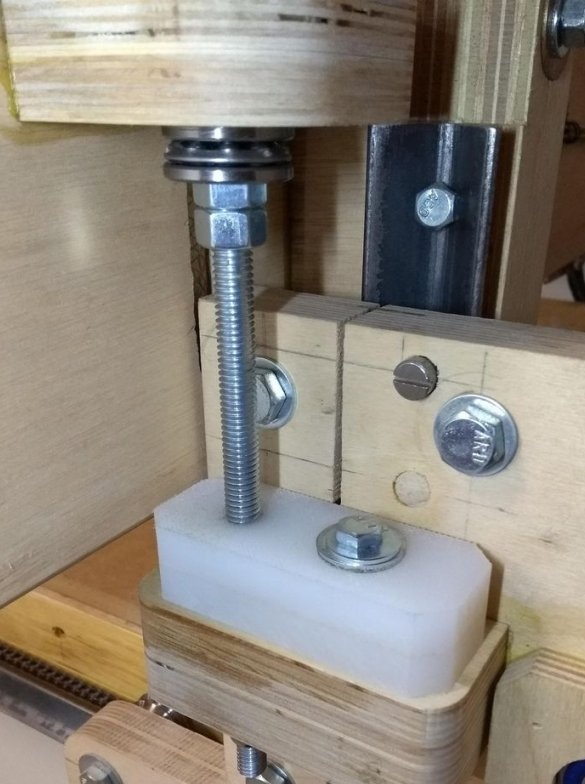

The portal is built of two layers of plywood glued together. A milling cutter is mounted on the transverse detail of the portal. The transverse part, together with the milling cutter, moves up / down along the same rails as in the previous step. Two stepper motors are installed to move along the edges. The master secured long bolts to the axes of the engines. At the bottom there is a knot with nuts. At a command, the engines begin to work, the shafts rotate, and the milling cutter drops or rises.

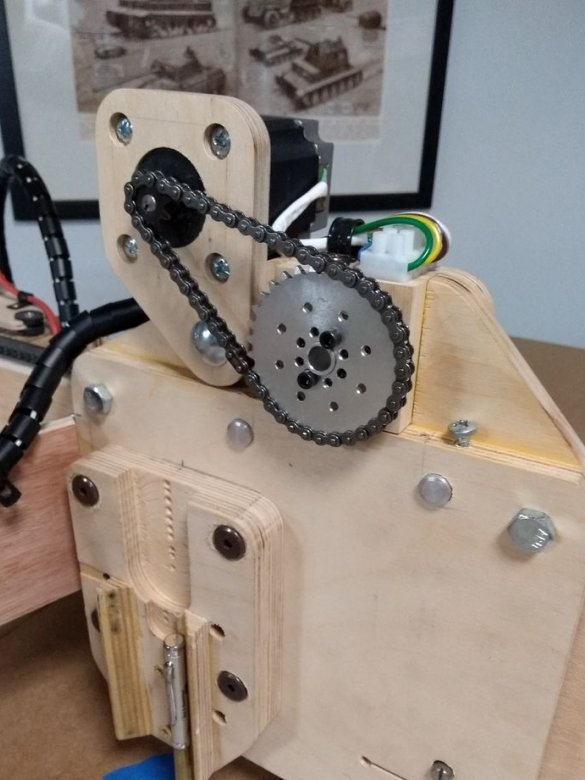

To move the carriage with the mill on the Z axis, the master uses a stepper motor and a chain gear.

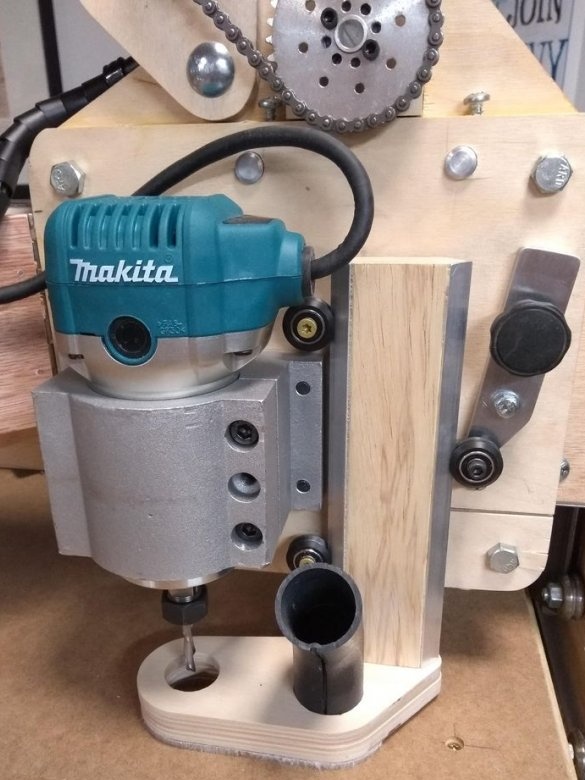

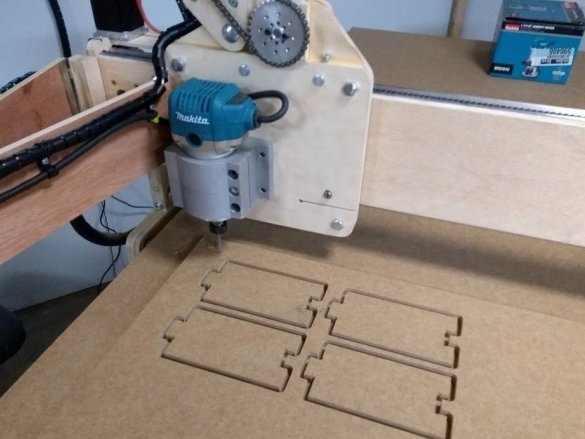

Step Four: Milling Cutter

A Makita RT0701C router is installed on the machine. Also, the master installs an adapter for connecting the hoses of the vacuum cleaner.

Step Five: Management

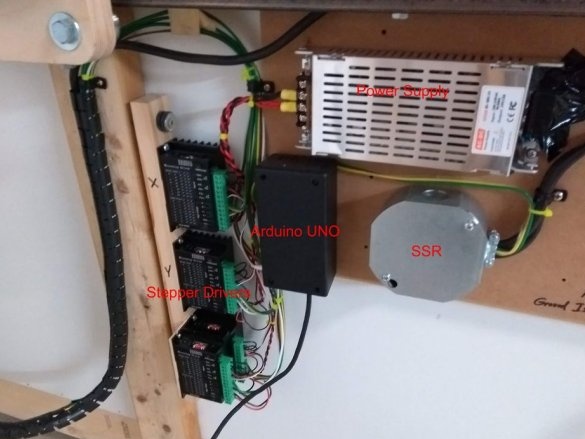

Management system based on Arduino UNO and a small PC with EstlCAM CNC software.

The Arduino Uno is mounted on the back of the machine and supports Estlcam controller software. The electrical box contains a 10A SSR (Solid State Relay), which turns the router on and off. On the left are TB6600 stepper drivers and a 24 V, 15 A power supply. The wires to the motors pass through the corrugation. A Windows 10 PC displays the image and is controlled by a wireless mouse and keyboard.

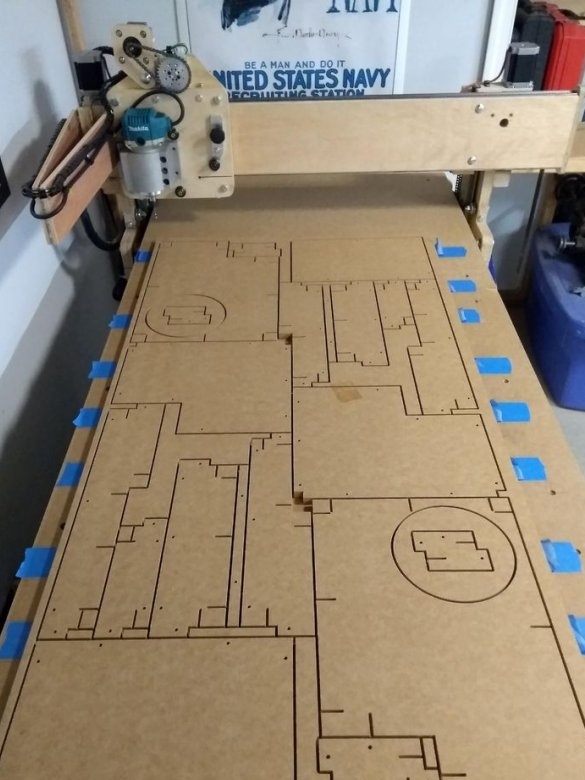

According to the master, the machine turned out to be quite normal, the last photo shows examples of how the machine works.