Some of you are engaged in carpentry, and quite often find unexpected solutions for yourself. For example, when assembling a frame for a table, one of the most difficult nodes is the connection of the rails and legs. Also, this type of construction comes across in other types of work.

In this article, the author of the YouTube channel “J-woodworking 목공,”, will tell you how easy it is to make such a connection only with a circular saw.

Materials

- Pine beam.

Instruments, used by the author.

— A circular saw

— DADO adjustable saw blades

— Clamps

- A pencil.

Manufacturing process.

First of all, the master dissolves the beam on long slats.

Since this will be a low Japanese table, the legs themselves will be very short.

Since the height of the disk is not enough to process the end face of the bar, the workpiece has to be turned over and processed on the other side.

For example, these blanks will be enough.

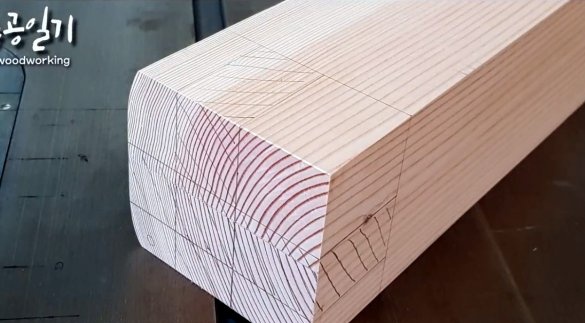

Now both legs are pressed against the stop, and a rail is applied from above. The master marks the legs on one side, then flips them 90 degrees, and puts a second mark.

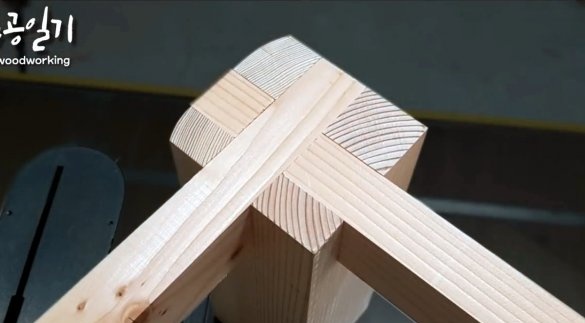

Next, the legs are installed in a vertical position, and the transverse marks of the rail profile are applied.

Here is the marking of the butt should succeed.

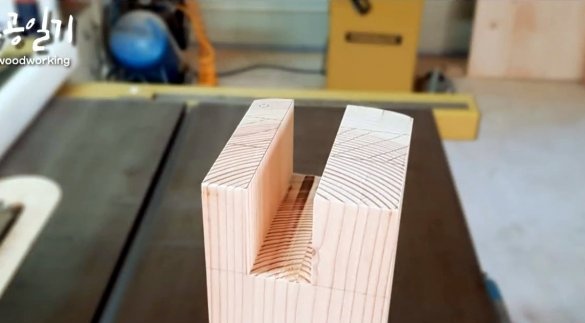

Then the master replaces the circular saw blade with DADO, and sets its height exactly with the width of the bar.

In two passes, the author gets an even cut. It is important to move the workpiece very slowly, this disk does not saw very quickly.

So, the first groove is ready, you can check the density of the rail.

The workpiece is rotated 90 degrees, and the second cut is performed.

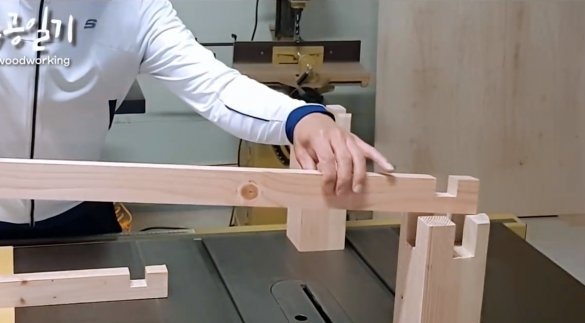

So the master processed both legs.

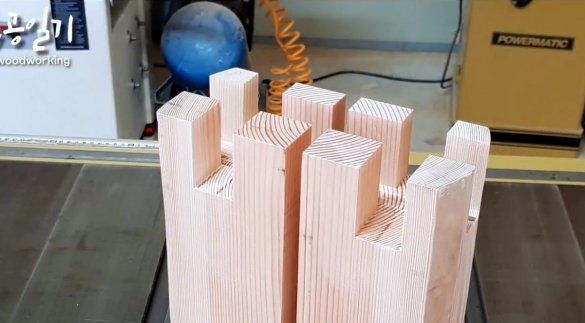

Now the slats are inserted into the grooves, and the marking of the edges of the groove is applied to them.

The disk is installed at half the width of the rails, and the first groove is made in two rails at once.

The master also uses the template for precise cutting, the workpieces are turned over, the second groove is cut.

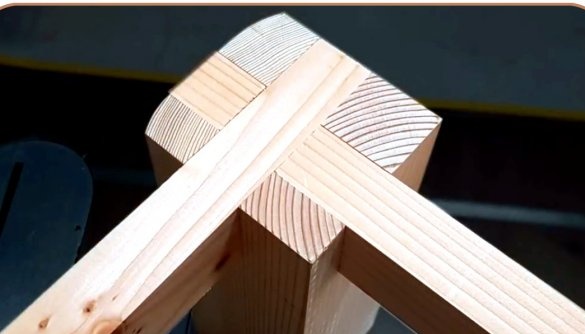

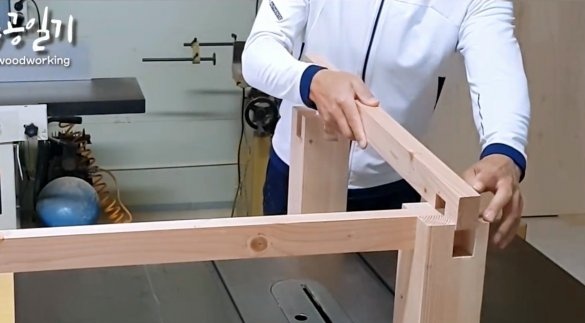

One rail turns upside down, and connects to the first. There is practically no backlash.

It remains only to assemble the corner joint. Even without screws and glue, everything holds on very firmly. You can even make a collapsible table frame design.

Thanks to the author for demonstrating a simple but very reliable triple corner joint.

All good mood, good luck, and interesting ideas!

Author video can be found here.