I welcome all fans to craft, I propose to consider instructions for the manufacture of a powerful furnace for the garage or workshop do it yourself. The furnace is assembled from a cylinder from under the compressor and is blown by a fan, resulting in increased heating efficiency. Thanks electronics, you can set the desired temperature at which the fan will automatically turn on, and you can also adjust the speed of the propeller. All of the available materials are assembled, but you will need a good welding machine, since you will need to cook thin steel. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- cylinder from under the compressor (or from under the gas);

- a cylinder of a larger diameter for the body;

- a round pipe for the chimney;

- fittings for grate;

- corner;

- Sheet steel;

- fan for 220V / 56 watts;

- bolts and nuts;

- door hinges;

- stainless steel grill;

- heat resistant paint;

- Electronics for propeller control.

Tool List:

- welding machine (TIG, semi-automatic or similar);

- plasma cutter;

- grinder;

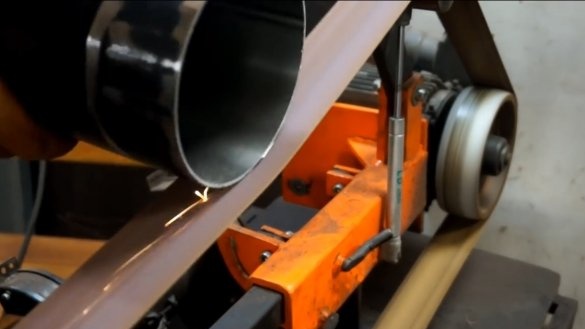

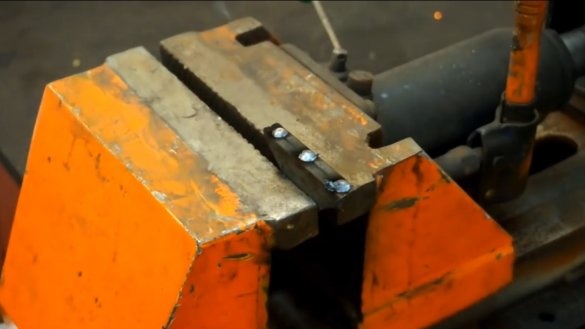

- tape cutting machine;

- tape cutting machine;

- drill.

Manufacturing process homemade:

Step one. Furnace body

First of all, we will make the furnace body, for this we need a cylinder of suitable sizes, the author used a cylinder from under the compressor. The steel of the container should be as thick as possible, then the furnace will last a long time.

We cut off the neck of the cylinder, remove all the paint with a grinder and then you can cut the doors. We will need to make a door for the furnace, as well as a door for the blower.

Step Two Grate

We make grate for the furnace, the author used reinforcement as a material. We weld the grate and weld it inside the furnace. Also, the author has welded pieces of the corner over the firebox, this will increase the rigidity of the structure and slightly increase the efficiency.

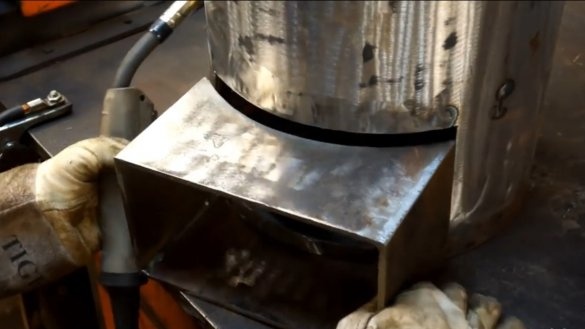

Step ThreeSleeves

We make sleeves for the furnace, on which we will hang the doors. Here we need sheet steel of suitable thickness, the sleeves must be strong and rigid. We cut the material and weld two parts. Next, the sleeves need to be well welded to the furnace body, the welds should be airtight. Here we need welding like a semiautomatic device, TIG or the like.

Step Four Chimney and bottom

In the upper part, using a grinder, cut a hole and install a chimney. If there is paint on the pipe, be sure to clean it all off, it will smoke when heated.

We also make the bottom for the furnace, the author cut it out of thick sheet steel and carefully welded it to the furnace. The bottom should be of such a diameter that it can be welded to the outer casing. And in order for the oven to abut against the body, a corner can be welded to it.

Step Five Housing

We make an external housing for the furnace, here we need a bigger cylinder already, the author found an old boiler or something like that. We cut the boiler so that it can be worn on top of an already manufactured furnace. It is also necessary to remove all paint from the body before assembly!

When everything is ready, we install the case in its place and weld the stove well, everything should be tight, through the case we will drive the air through the fan.

From the inside, the author welded the body to the furnace with the help of corners. At the end, we make legs for the furnace from pieces of a profile pipe.

Step Six Blowdown windows and fan space

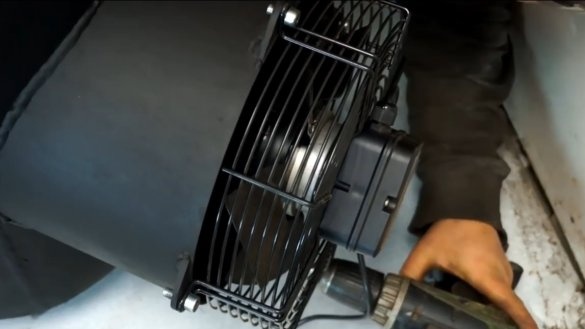

We cut out windows in the furnace body through which we will pump air. We cut one window in the lowest part, behind the furnace, a fan will be installed here. Under the fan, we make a sleeve of sheet steel and manufacture fasteners so that the fan can be screwed.

The second window is located at the highest point from the front, hot air will already come from here.

Seventh step. Doors

We make doors out of sheet steel, hang them on good door hinges. In the bottom door we cut another window and install a small valve, the gap will be regulated by a bolt. In this way, we can precisely control the air supply to the furnace.

Step Eight. Lattice and painting

The output window must be decorated and protected from debris entering it. For such purposes, you need a grill, we weld it to the body. The author found a stainless steel grill.

When everything is ready, we paint the oven with heat-resistant paint in a color to your taste.

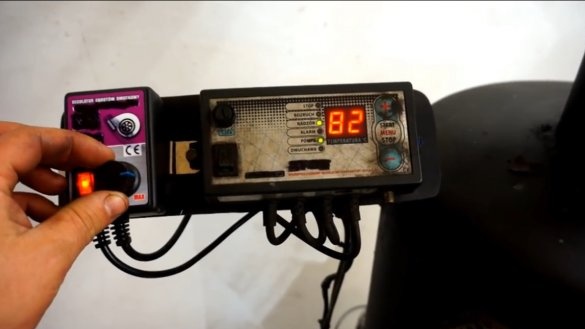

Step Nine. Fan installation and testing

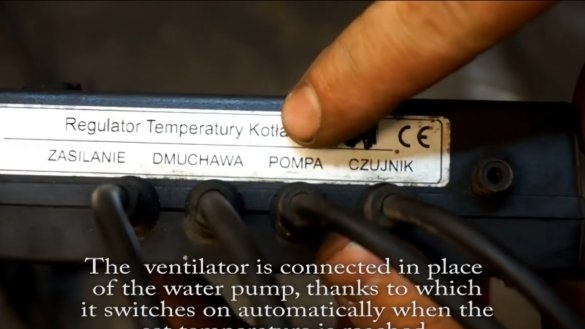

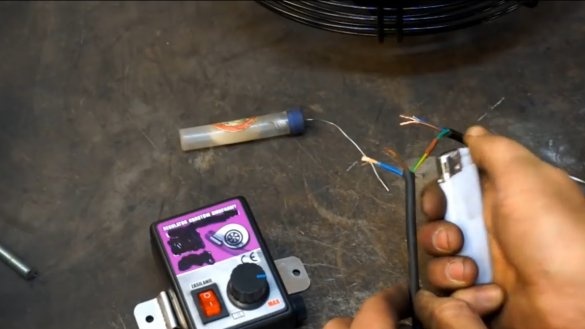

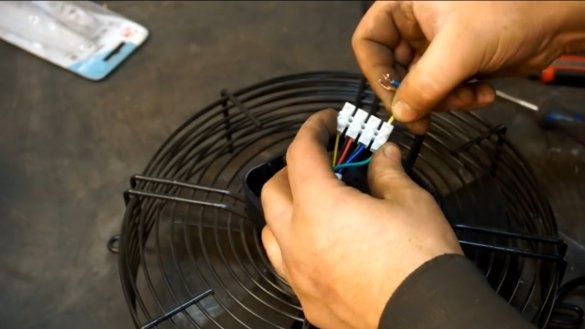

We install the fan in its place and connect the electronics. The fan itself will turn on when the temperature inside the case reaches a certain value. For temperature control, the sensor is located, which is located inside the case. As for the propeller revolutions, they can be adjusted manually using a dimmer.

Thanks to the blasting of the furnace, everything works efficiently, and steel does not overheat, as a result, the service life of the furnace increases. The design is dangerous because in case of burnout of the furnace, the fan can start to drive smoke or carbon monoxide, however, not a single furnace is safe from this.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!