I welcome all fans to craft, I propose to consider instructions for the manufacture of a simple machine for splitting chips do it yourself. Such a machine can be put in the garage or in the right place, having a private home. The advantage of the machine is that it is silent compared to an ax and you do not need a stump for splitting. Even a woman can work on such a machine, getting the right amount of chips for kindling. Everything is going to be quite simple, if the project interests you, I suggest studying it in more detail!

Materials and tools used by the author:

Material List:

- an unnecessary ax;

- profile pipes;

- channel;

- steel plates;

- round timber;

- spring;

- spring;

- paint;

Tool List:

- grinder;

- welding machine;

- drill;

- tape cutting machine;

- vise;

- tape measure, marker.

Manufacturing process homemade:

Step one. Knife making

First of all, we will make a knife that will chop wood. For these purposes, the author used an unnecessary ax. The ax must be cut off from the ax, in the end only the blade should remain.

An axis must be welded to both sides of the blade, which will be attached to the main frame. Here you will need a profile pipe with a thick wall, but it’s better to take a stronger one, for example, a steel bar.

Step Two Base

We weld a reliable base for the machine so that it does not fall. The author used wide rectangular shaped pipes as a material. As a result, it was necessary to properly weld together two pieces of the pipe between each other.

During the assembly process, the author will still weld pieces of profile pipes to the base to increase the area of the base.

Step Three Racks

We make racks, thanks to them we will fix the axis with a knife, and also fix the lever with which we will press on the wood. Racks can be made from a corner or channel. In racks, the author drilled holes, they are needed so that the knife can be adjusted in height for different lengths of chocks.

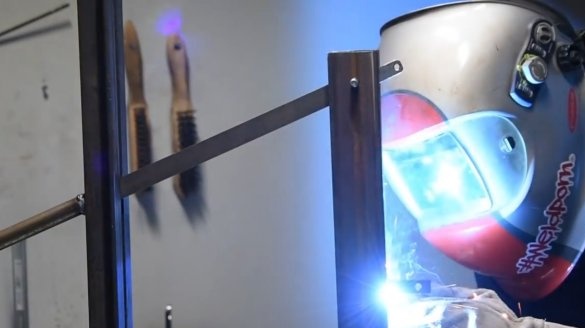

Racks are strictly at right angles welded to the base, everything must be welded very reliably.

Step Four Lever and Ears

We make a strong lever, it can be made of round timber, grinding metal in those places where the lever will pass into the slots in the racks. At the end of the lever there should be an ear under the spring, which will return the lever to its original position. The second ear is welded to the stand, the ears can be made of steel plate.

Step Five Assembly and testing

We sharpen the ax to the state of a razor, a grinder with a petal nozzle will perfectly help with this. Having painted all the details, you can assemble the machine, install the spring, it must be quite strong to return such a long lever to its original position. The homemade product works perfectly, the author perfectly pricks chips for kindling the furnace.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!