Surely many of you often come across various types of grinding work. However, there are situations when using standard tools it is extremely difficult to process the inner surface of round holes.

In this article, Mikhail, the author of the YouTube channel “Good Master”, will tell you how he made a simple device for these varieties of work. This is the so-called drum grinding nozzle for a screwdriver or drill.

Materials

- Oak plank

- Steel bolt, nut, washer M10

- Ball bearing 6200

- Steel blank

- Second glue

- Sandpaper

- Double-sided tape.

Instruments, used by the author.

— Screwdriver

— Crowns, drill

- Lathe.

Manufacturing process.

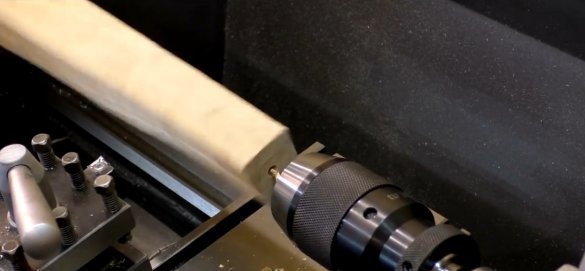

The master will use an oak board as the main material for the handle and drum. He dissolves it into whetstones, and grinds it on a lathe.

Then the handle is cut off.

Then the drums themselves are made, and a hole with a diameter of 12 mm is drilled into them.

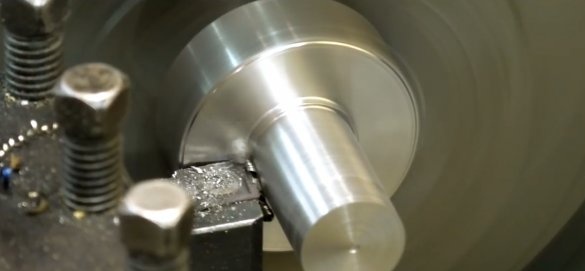

An axle for a drum will be made of a steel bolt M10. The master immediately grinds part of the thread, this part of the part will be fixed in the chuck of a screwdriver. Also, a groove is made on the head under the inner diameter of the bearing.

In order to reduce the beating to a minimum, the master puts the drum on the axis, and grinds it again.

Then the surface of the cylinder is carefully ground. Such processing will reduce the likelihood of beats, and extend the service life of both the bearing in the handle and the screwdriver itself.

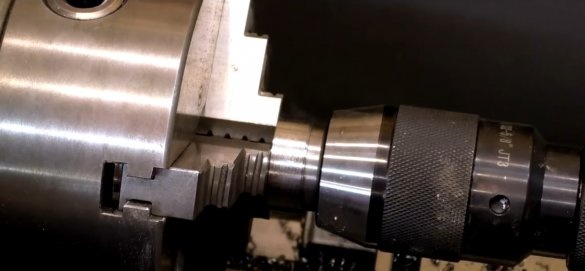

Now you need to make an insert in the handle, and grind one edge of it.

On the other side of the workpiece, the bearing seat is machined.

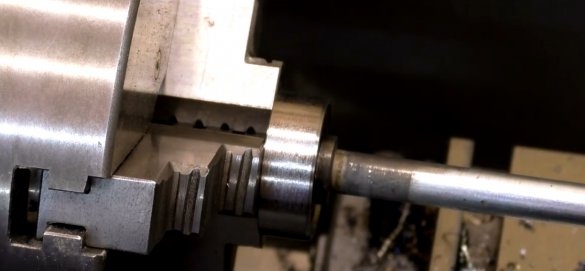

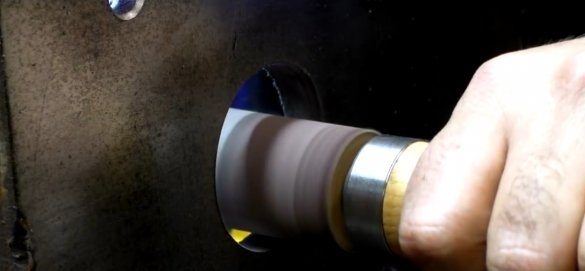

The bearing is pressed into place with the tailstock quill. Then the axis is pressed in.

The axis holder is glued into the handle using ordinary second glue. The wooden surface of the handle is impregnated with linseed oil, and covered with wax.Also in recent article I already talked about the impregnation recipe from Vladimir Natynchik. He told how to impregnate oil-wax from natural rosehip oil and beeswax. This recipe is noteworthy in that it can be used even on products in contact with food.

Thin double-sided tape is great for fixing sandpaper on the drum.

That's all done, the tool can be assembled.

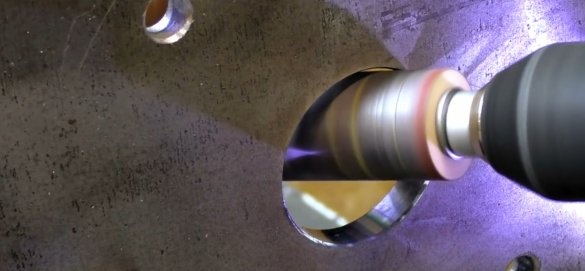

The master for one of his projects had to drill a thick sheet metal with a crown, and after it remained quite serious flaws.

The author uses sandpaper of the 120th and 400th grit. If you want, you can make several drums ahead of time with paper of different grain sizes. You can also vary the diameter of the cylinder.

In just a few minutes, the edge of the hole is finished.

You can also optionally chamfer. This is another matter!

I thank the author for a simple but useful tool for the workshop!

If you have interesting homemade products, share them on this site. Here you will get a real reward, not a “bunch of green stuff" at the entertainment forum.

All good mood, good luck, and interesting ideas!

Author video can be found here.